One-time pouring concrete inverted arch and construction method thereof

A technology for pouring concrete and construction method, which is applied in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of long conversion time, prolonged construction period, large design funds and manpower, etc., to shorten construction time, improve construction efficiency, The effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

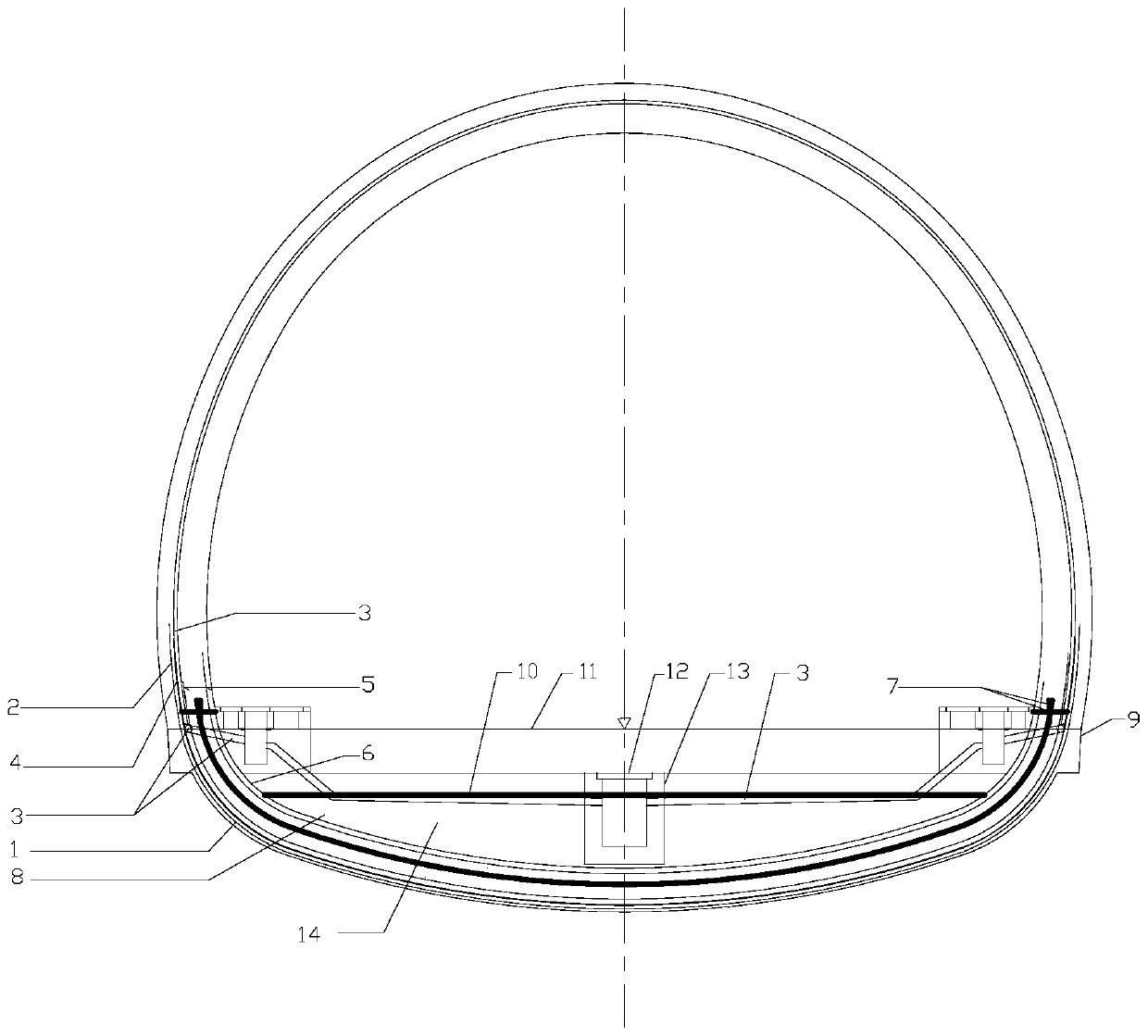

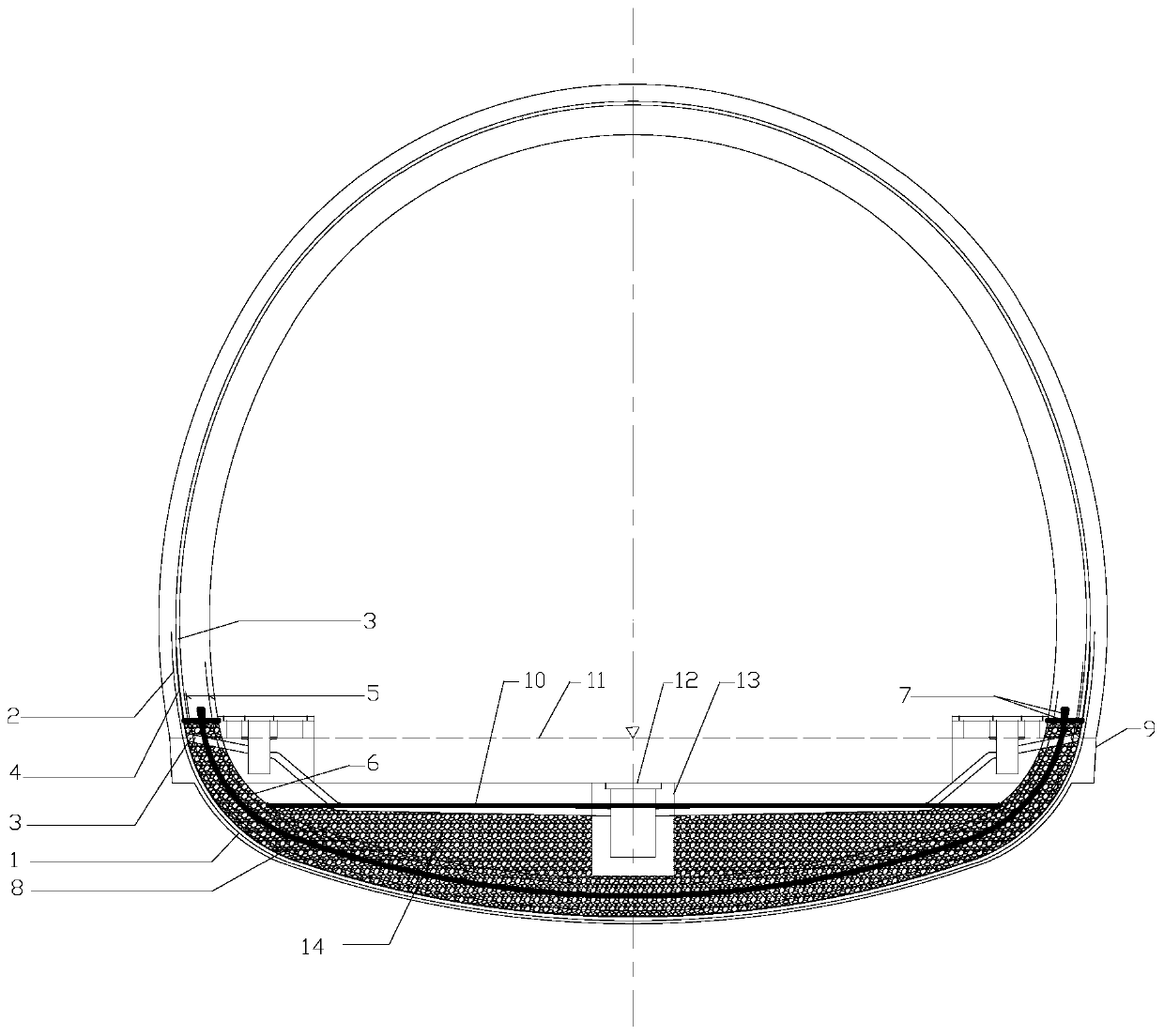

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 2 The tunnel tunnel face shown in , the outermost layer is the primary support 1 of the inverted arch, and the low side walls 9 of the inverted arch on both sides of the lower part start with the secondary lining of the inverted arch formed by pouring the inverted arch concrete 8 , and in the middle of the lower part Fill concrete 14 for the inverted arch. The secondary lining of the inverted arch in the prior art refers to a layer of reinforced support layer uniformly poured inward along the initial support 1 of the inverted arch, with embedded steel bars and a complete set of closed formwork, including After the inverted arch formwork in the middle of the inverted arch, usually high-grade C50 concrete can be used to pour from the window of the formwork. After pouring, the inverted arch formwork is removed, the central gutter formwork is installed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com