Oil pump rotor assembly

A rotor and component technology, applied in the field of oil pump rotor component structure, can solve problems such as application limitation, meshing impact, and reduce displacement, and achieve the effects of wide practical value, stable operation, and avoiding oil trapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

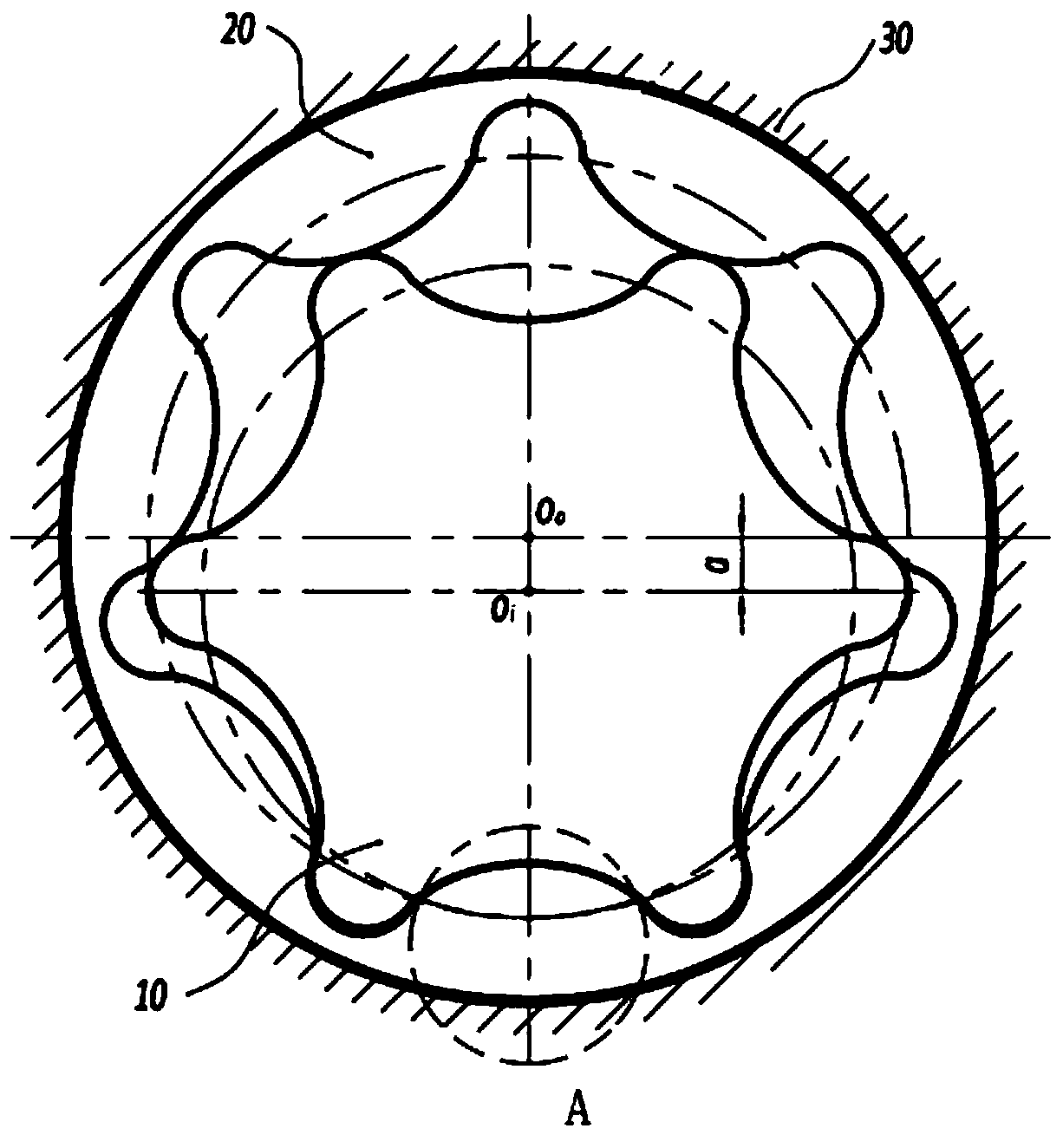

[0025] This embodiment provides an oil pump rotor assembly, including an inner rotor 10 and an outer rotor 20 arranged in a rotor chamber of a casing 30 .

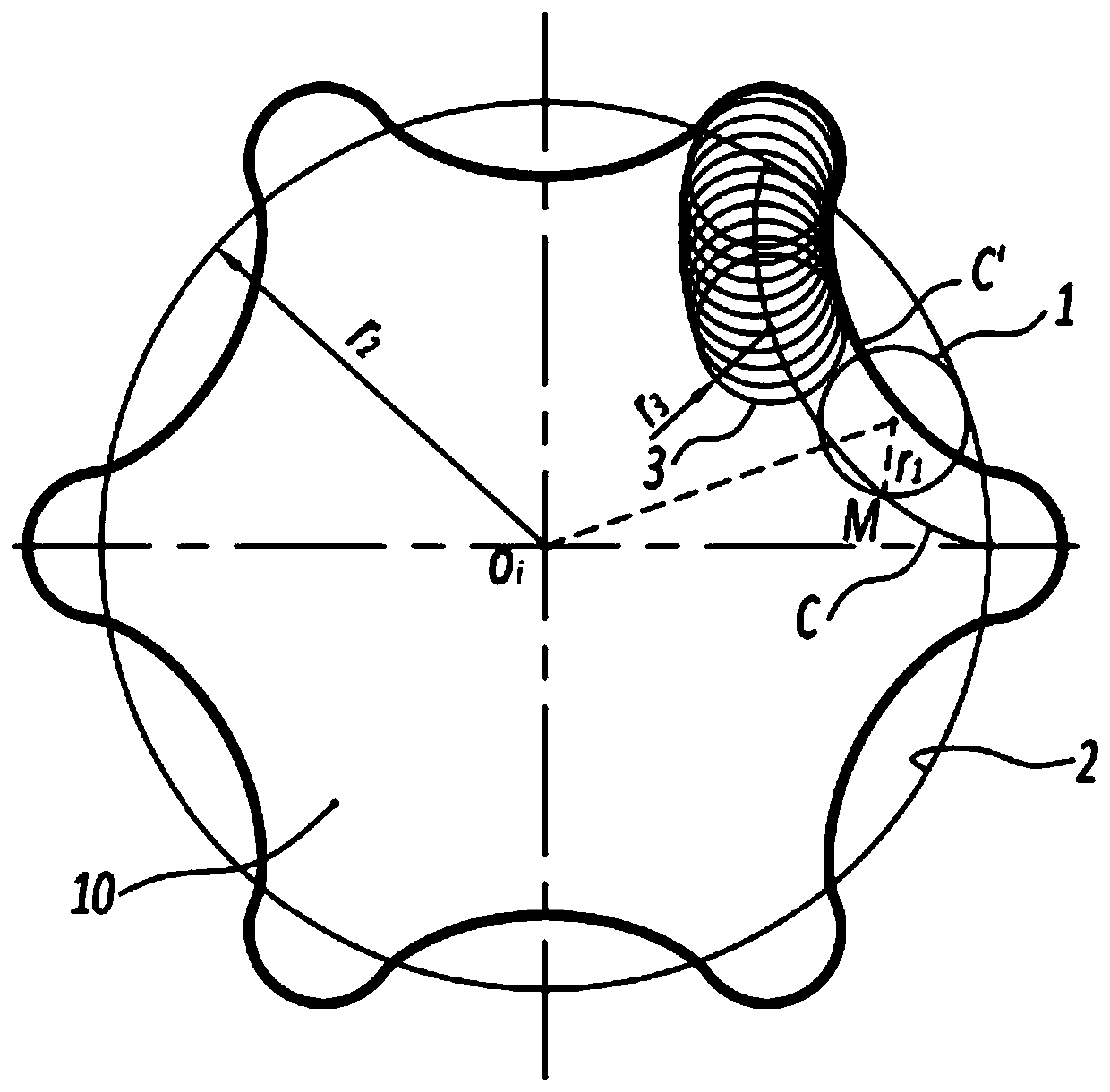

[0026] The tooth profile profile of the inner rotor 10 has a radius r 3 And the envelope curve C' of a set of trajectory circle I3 whose center is on the hypocycloid C. The hypocycloid C is the locus of a fixed point M on the circumference of the rolling circle I1 when the rolling circle I1 is inscribed on the base circle I2 for rolling without slip. The radius of the rolling circle I1 is r 1 . The radius of the base circle I2 is r 2 .

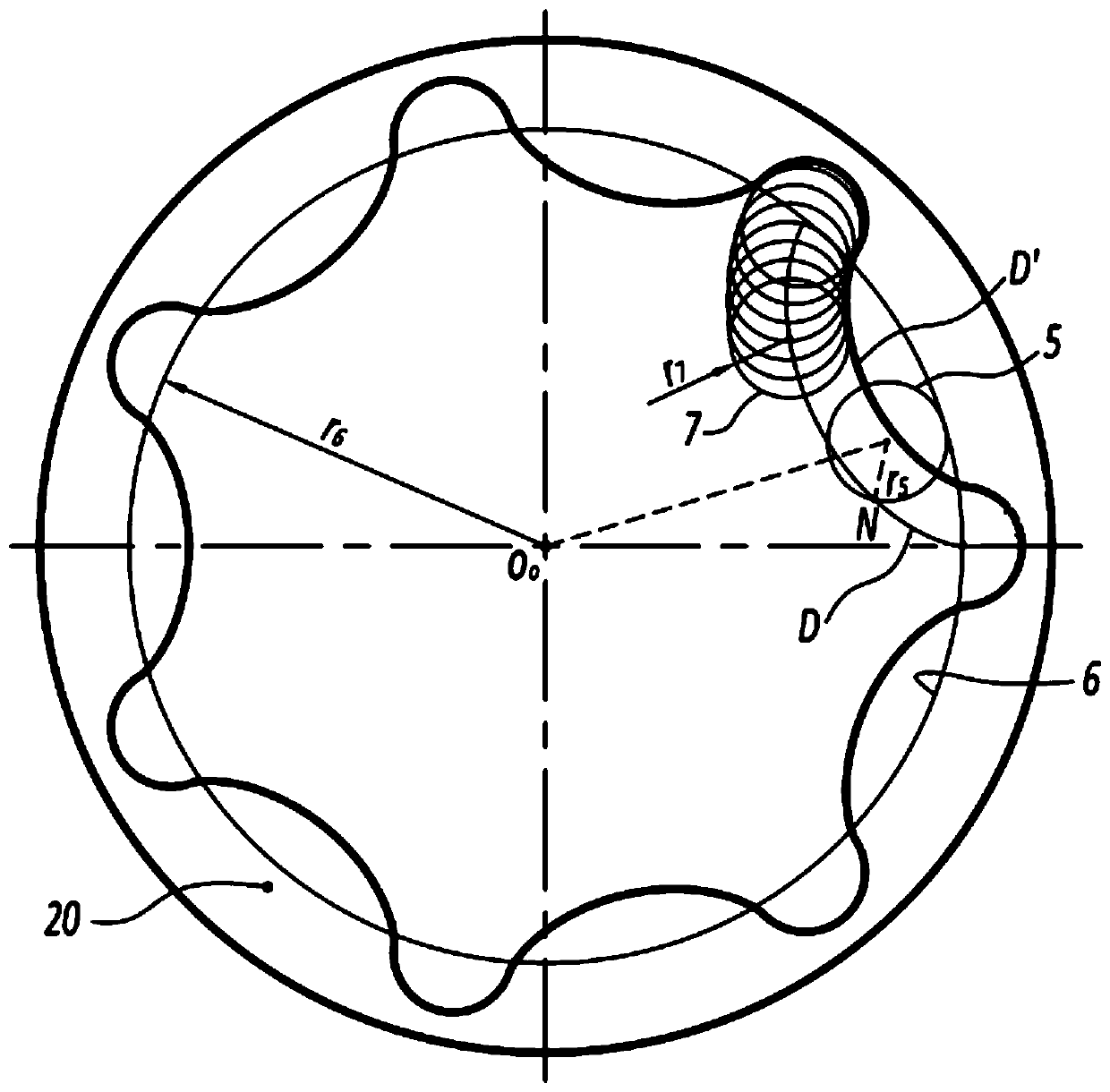

[0027] The tooth profiles of the outer rotor 20 have a radius r 7 And the envelope curve D' of a set of trajectory circle II7 whose center is on the hypocycloid D. The hypocycloid D is the locus of a fixed point N on the circumference of the rolling circle II5 when the rolling circle II5 is inscribed on the base circle II6 for rolling without sliding. The radius r of the spherical I...

Embodiment 2

[0031] This embodiment provides an oil pump rotor assembly, including an inner rotor 10 and an outer rotor 20 arranged in a rotor chamber of a casing 30 .

[0032] see figure 1 , the inner rotor 10 is in conjugate engagement with the outer rotor 20 . The inner rotor 10 has 6 teeth and the outer rotor 20 has 7 teeth. The casing 30 has a suction port for sucking fluid and a discharge port for discharging fluid. The inner rotor 10 and the outer rotor 20 are conjugated in constant ratio transmission. The center of the inner rotor is O i , the center of the outer rotor is O o , the center distance between the inner rotor 10 and the outer rotor 20 is a.

[0033] see figure 2 , the formation process of the tooth profile of the inner rotor 10 is as follows: the rolling circle I1 is inscribed with the fixed base circle I2 and performs pure rolling, and the trajectory of a point M on the rolling circle I1 forms a hypocycloid C. The hypocycloid C is closed, and the hypocycloid C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com