Conduction-oil boiler based on combustion of biomass gas

A heat-conducting oil boiler and biomass gas technology, which is applied in the treatment of combustion products, combustion chambers, combustion methods, etc., can solve problems such as low thermal efficiency of boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

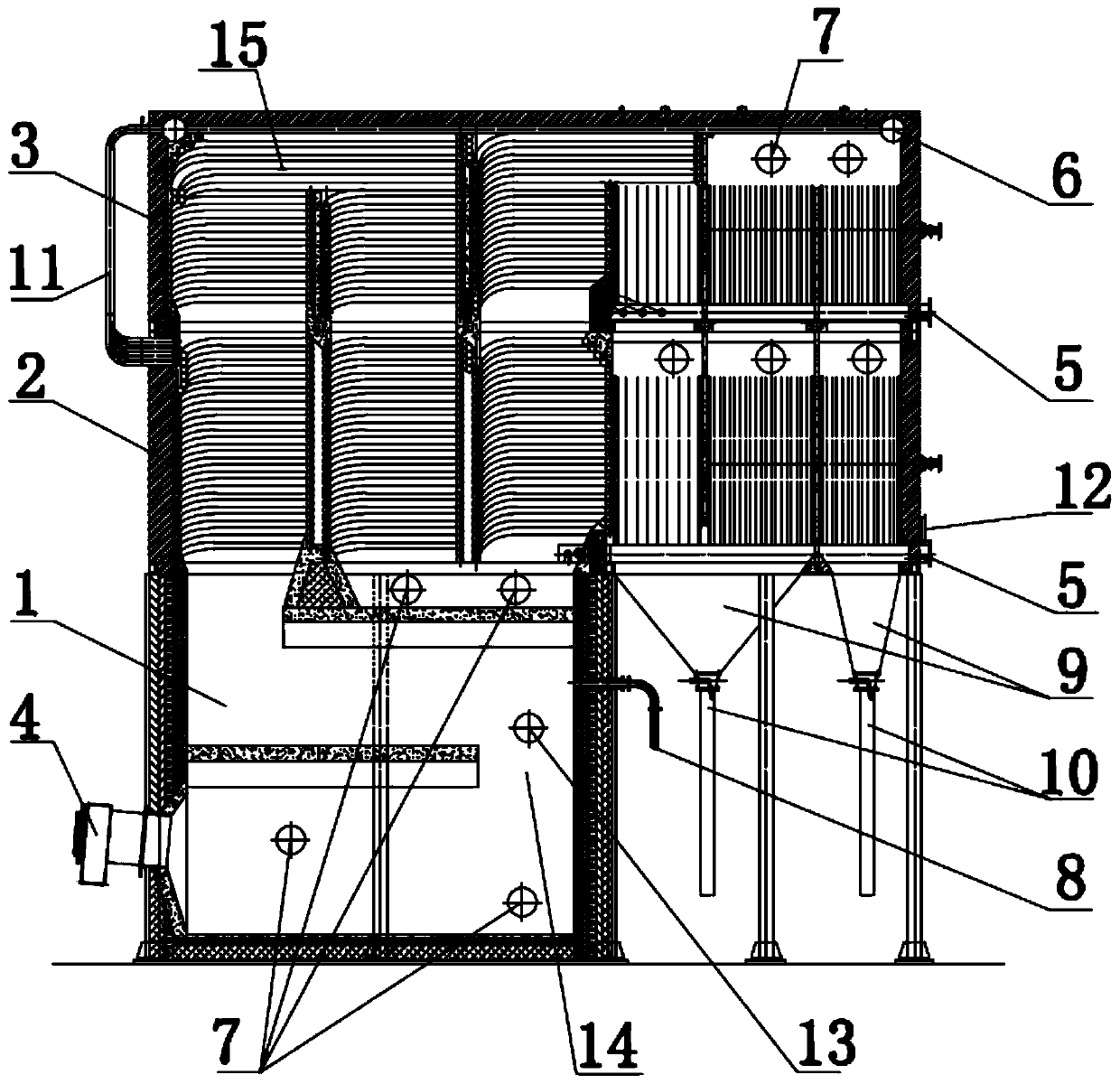

[0026] The specific embodiment of the present invention is as figure 1 As shown, a heat-conducting oil boiler burning biomass gas includes a boiler body arranged up and down and a combustion chamber 1. The gas inlet end of the combustion chamber 1 is provided with a biomass gas burner 4, and the flue gas outlet of the combustion chamber 1 is The end communicates with the flue gas inlet end of the boiler body. The inner cavity of the combustion chamber 1 is provided with at least one first bending channel 14 along the gas flow direction. In this embodiment, the number of the first bending channel 14 is one, and its bending angle is 180 degrees. Under the premise of not needing to increase the size of the combustion chamber 1, its internal space can be utilized to the maximum extent to prolong the combustion of biomass gas. Residence and burn times in chamber 1. There is a horizontally arranged furnace arch in the middle of the inner cavity of the combustion chamber 1. The fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com