Multidimensional mechanical arm 3D radar material level scanner

A robotic arm, multi-dimensional technology, applied in the direction of manipulators, mechanical equipment, instruments, etc., can solve the problems of high price, only measurement, inaccurate precision data, etc., to achieve the effect of high density, increase measurement range, and improve cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention is described in more detail to facilitate understanding of the present invention.

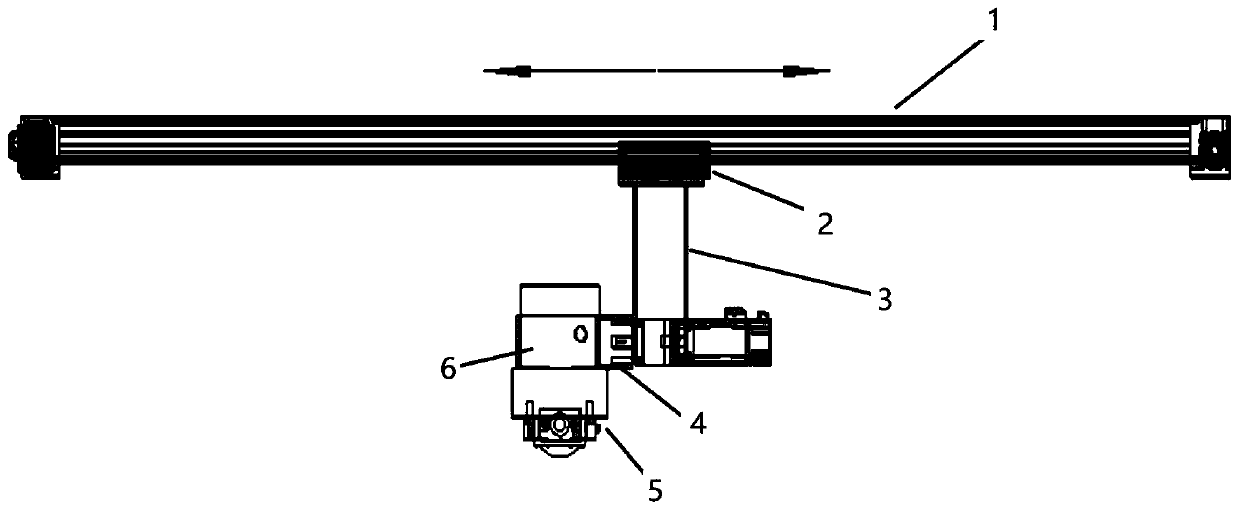

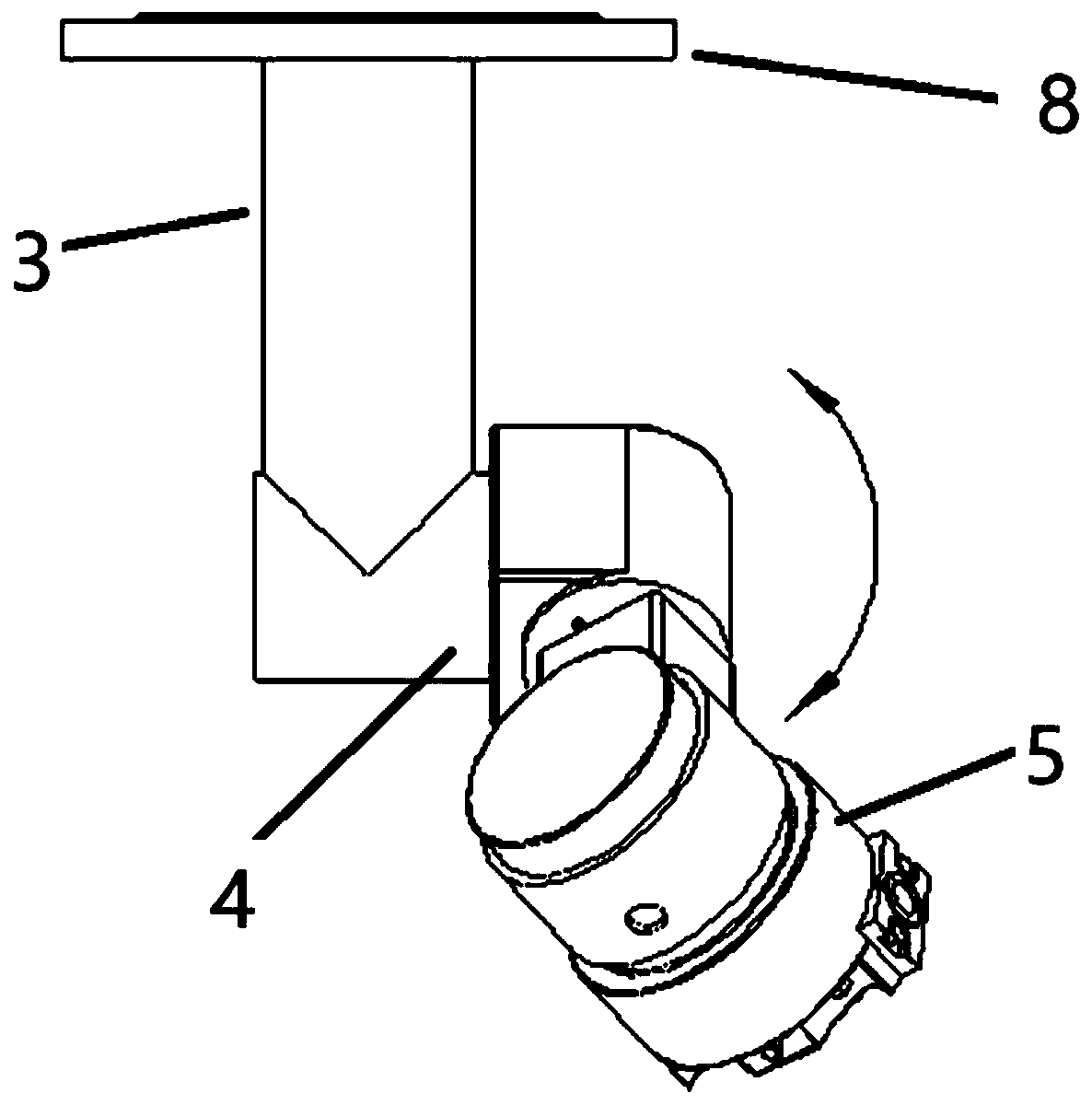

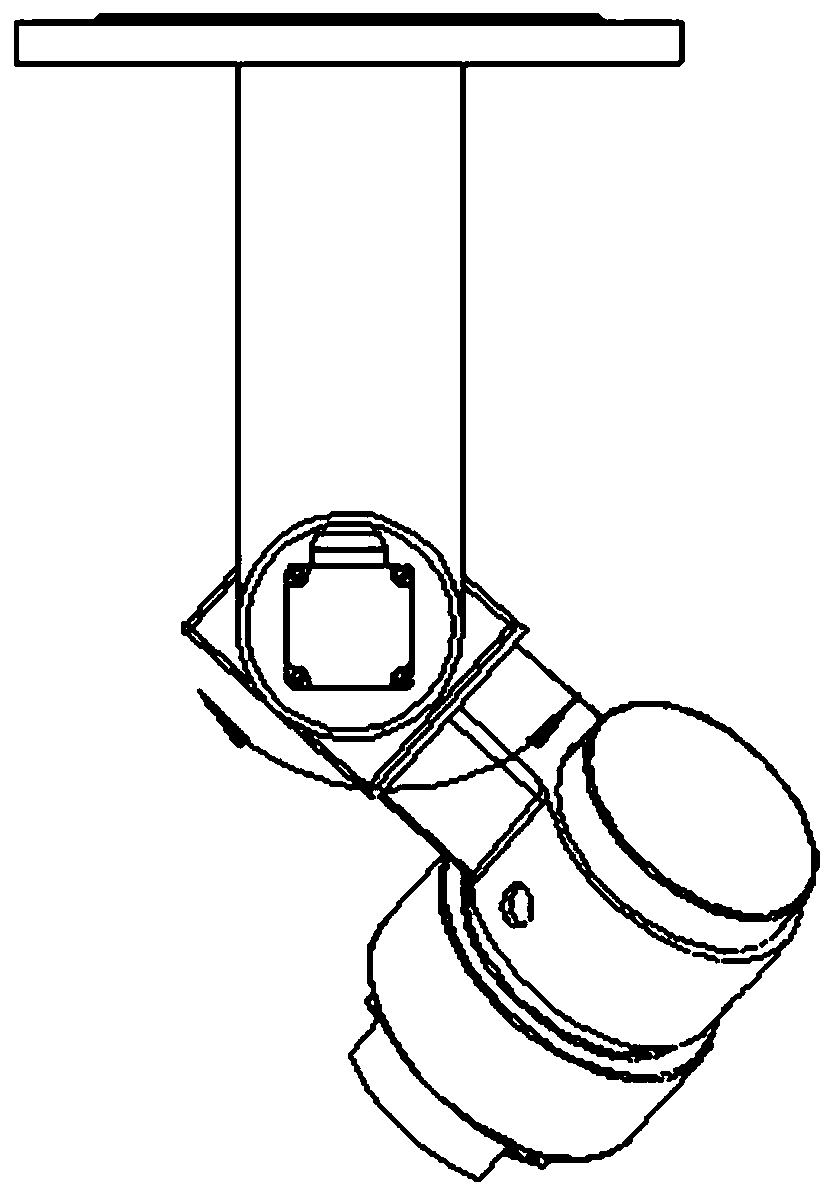

[0033] Such as Figure 1 to Figure 9 As shown, the multi-dimensional manipulator 3D radar level scanner of the present invention includes a track 1, a base 2, a first manipulator 3 (the first manipulator can use a stacker-reclaimer or an aircraft mounted on the track, crane etc.), the second mechanical arm 4 and the radar 5, the radar is installed on the end of the second mechanical arm, and the radar can turn and reciprocate at the end of the second mechanical arm; the second mechanical arm The top end of the first mechanical arm (the first mechanical arm can be replaced by a stacker-reclaimer installed on the track or an aircraft, a crane, etc.), the first mechanical arm (the first mechanical arm can be replaced by a stacker-reclaimer installed on the track The top of the stacker-reclaimer or aircraft, crane, etc.) is installed on the flange 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com