Self-supporting carbon nanofiber load molybdenum disulfide composite material, and preparation method and application thereof

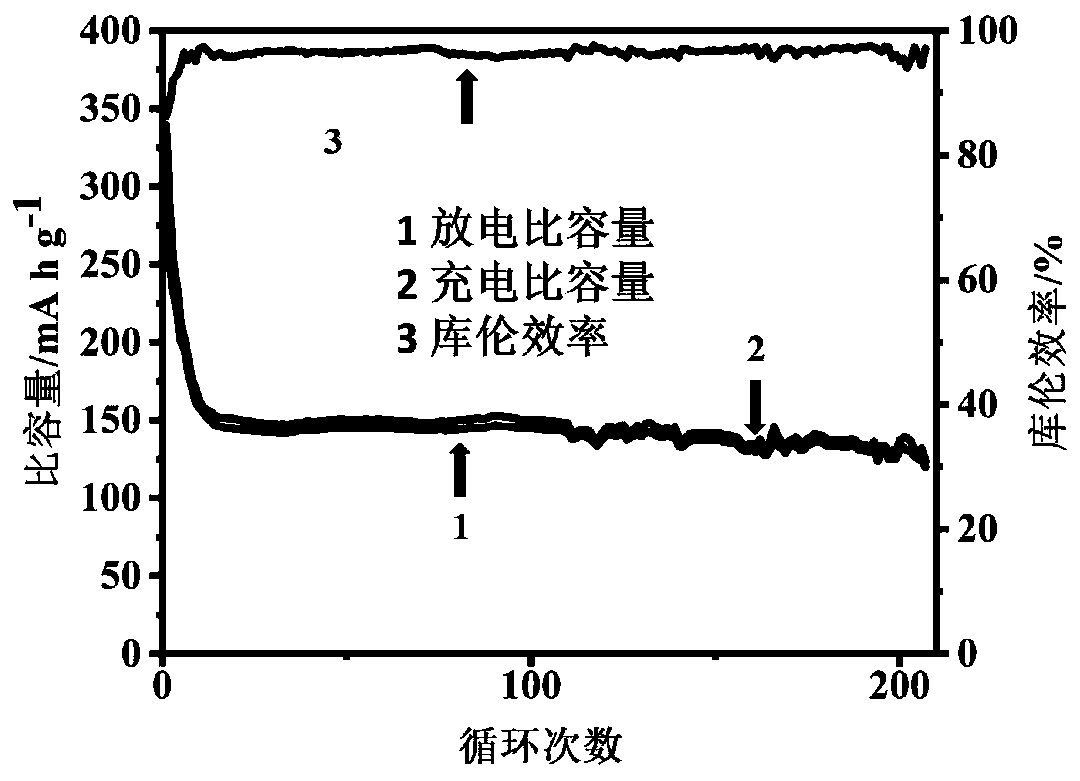

A technology of carbon nanofibers and molybdenum disulfide, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor cycle stability, battery performance degradation, and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of self-supporting carbon nanofiber loaded molybdenum disulfide composite material, comprising the following steps:

[0033] Will (NH 4 ) 2 MoS 4 The powder is dissolved in N,N-dimethylformamide and then polyacrylonitrile is added to obtain an electrospinning precursor;

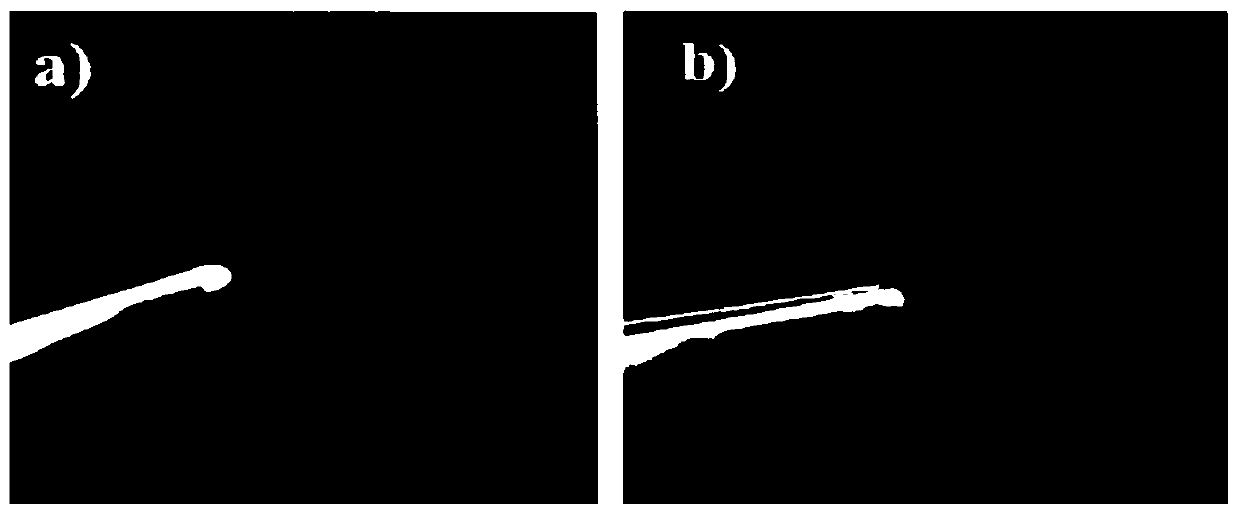

[0034] Spinning and jetting the electrospinning precursor to obtain fibers;

[0035] Pre-oxidizing the fiber in an air atmosphere to obtain a pre-oxidation product;

[0036] The preoxidized product was placed in Ar-H 2 Reduction is carried out in a mixed atmosphere to obtain a reduction product;

[0037] The reduction product is carbonized in an inert atmosphere to obtain the self-supporting flexible carbon nanofiber supported molybdenum disulfide composite material.

[0038] The present invention will (NH 4 ) 2 MoS 4 The powder is dissolved in N,N-dimethylformamide and then polyacrylonitrile is added to obtain an electrospinning precursor. ...

Embodiment 1

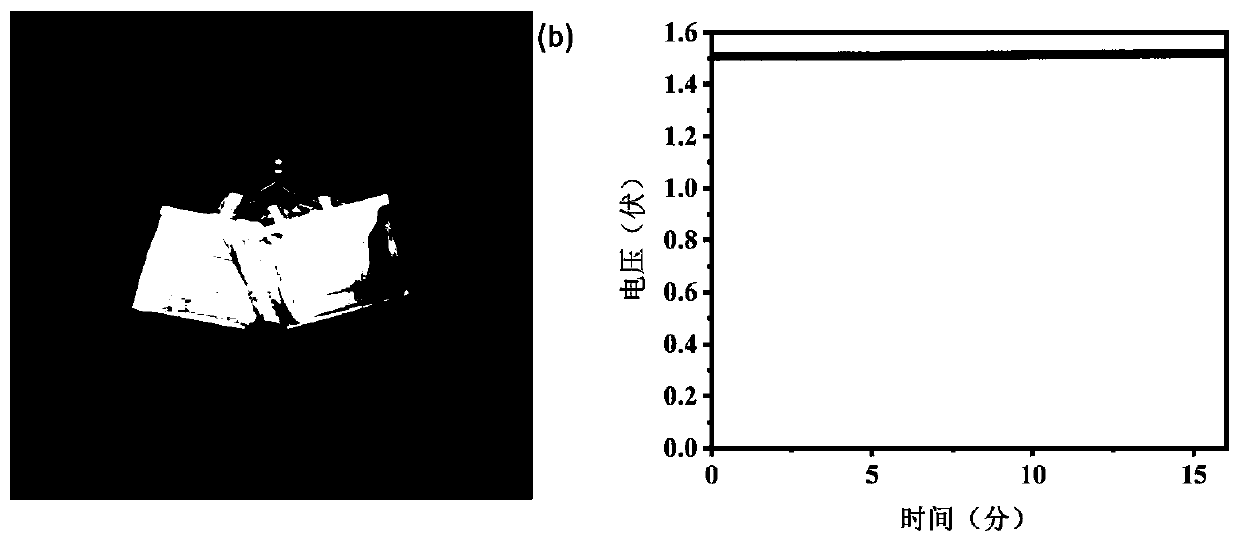

[0059] Step 1: Self-supporting flexible carbon nanofibers loaded MoS 2 Preparation of composite materials

[0060] Preparation of electrospinning precursors:

[0061] Will (NH 4 ) 2 MoS 4 After grinding into a micron-level (below 100 micron) powder with an agate mortar, weigh (NH 4 ) 2 MoS 4 Dissolved in N,N-dimethylformamide solution, after fully dissolved, add polyacrylonitrile (Mw=120,000) to prepare electrospinning precursor, (NH 4 ) 2 MoS 4 The mass ratio to polyacrylonitrile is 0.5:1, the concentration of the electrospinning precursor is 8%, and the electrospinning precursor is obtained after magnetic stirring at 50° C. for 8 hours.

[0062] Electrospinning process:

[0063] The prepared electrospinning precursor was sucked into a 10 mL medical syringe, and a needle with a diameter of 1.6 mm was used for spinning jet. The electrospinning voltage was 20KV, the distance between the needle and the receiving plate was 15cm, and the advancing speed was 10μL / min.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com