Modular DC energy consumption device and control method

An energy-consuming device and a modular technology, which is applied in the direction of load balancing in the DC network, voltage adjustment of the AC network, integration of the power network operating system, etc., can solve problems such as low reliability, power failure, and voltage increase of the DC transmission line. , to achieve good reliability and safety, reduce the difficulty of equipment manufacturing, and reduce the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing.

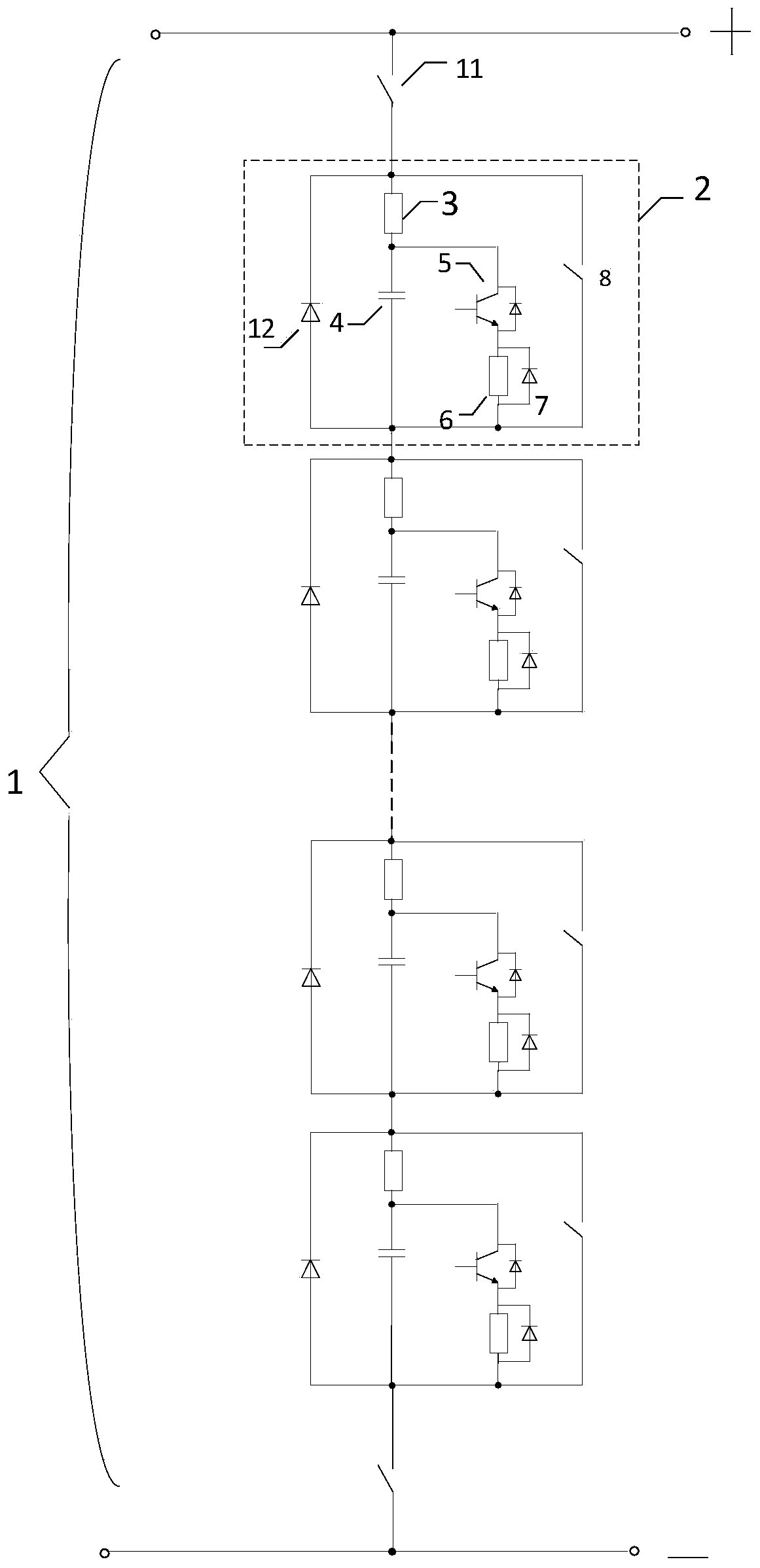

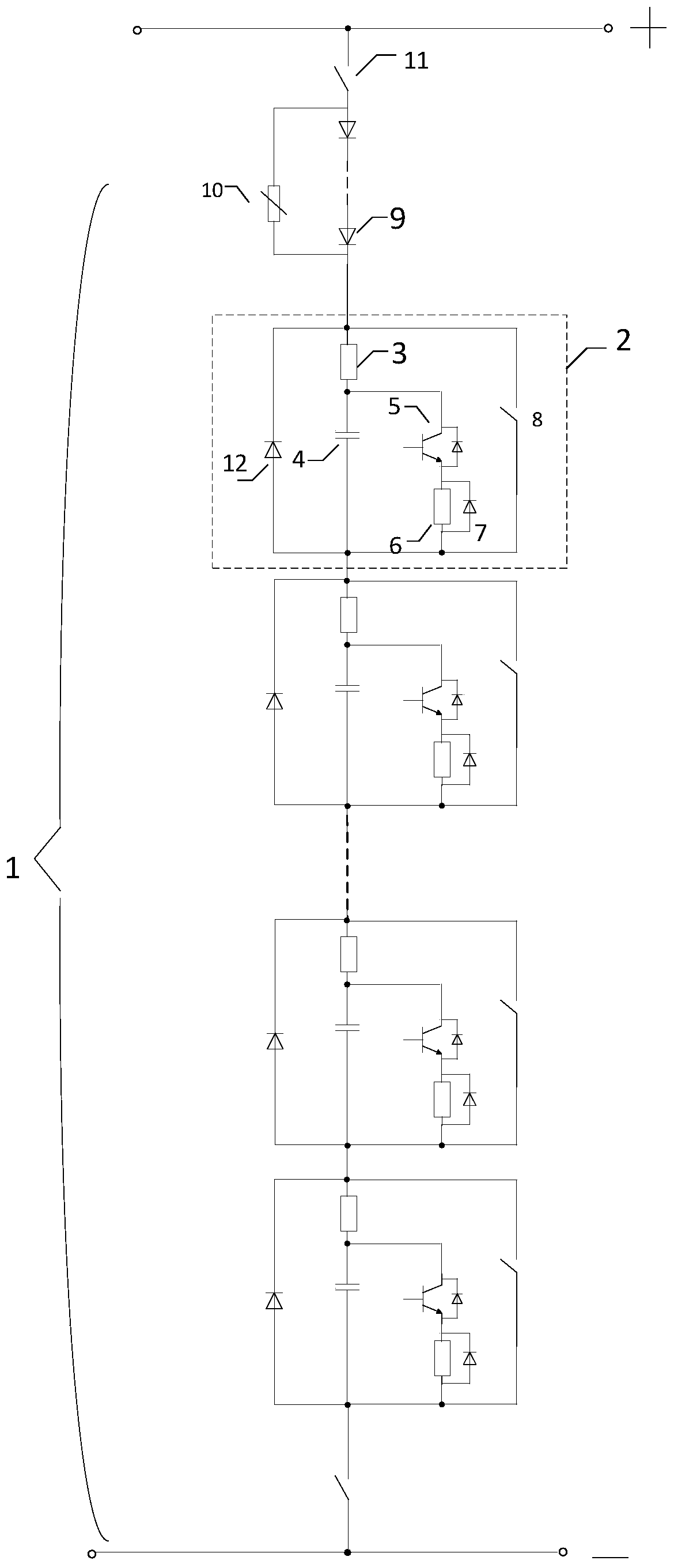

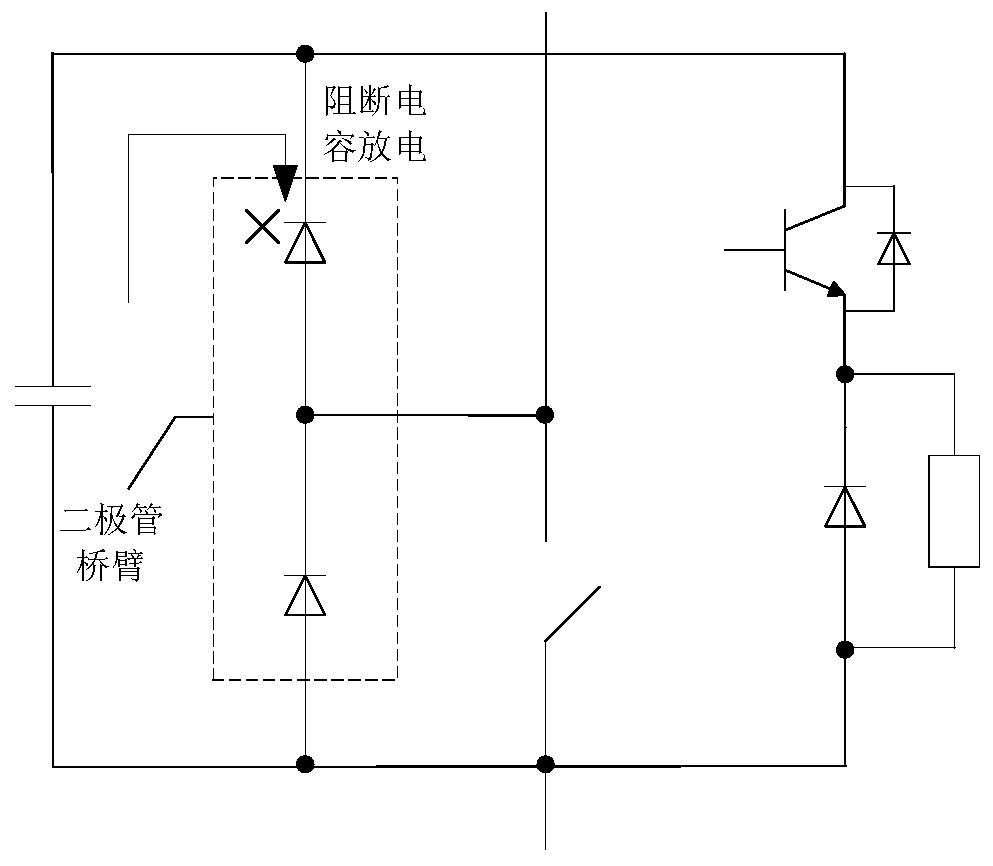

[0046] like figure 1 As shown, the device 1 includes at least two equalizing energy consumption modules 2, and the at least two equalizing energy consuming modules are connected in series in the same direction; the equalizing energy consuming module includes a DC capacitor 4, a current limiting unit 3, Energy consumption branch and bypass switch 8, the DC capacitor is connected in series with the current limiting unit to form a first series unit, and the head end and tail end of the first series unit are used as the head end and tail end of the voltage equalization energy consumption module ; The energy consumption branch is connected in parallel at both ends of the DC capacitor, and the energy consumption branch includes a first power semiconductor device 5 and an energy consumption resistor 6 connected in series; the current limiting unit includes a device with a current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com