Device and method for laboratory glass sample melting

A laboratory and sample fusion technology, applied in glass furnace equipment, glass manufacturing equipment, furnace types, etc., can solve problems such as excessive viscosity difference between upper and lower sides, uneven composition, etc., to achieve elimination of glass streaks, uniform composition, and reduced gas content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

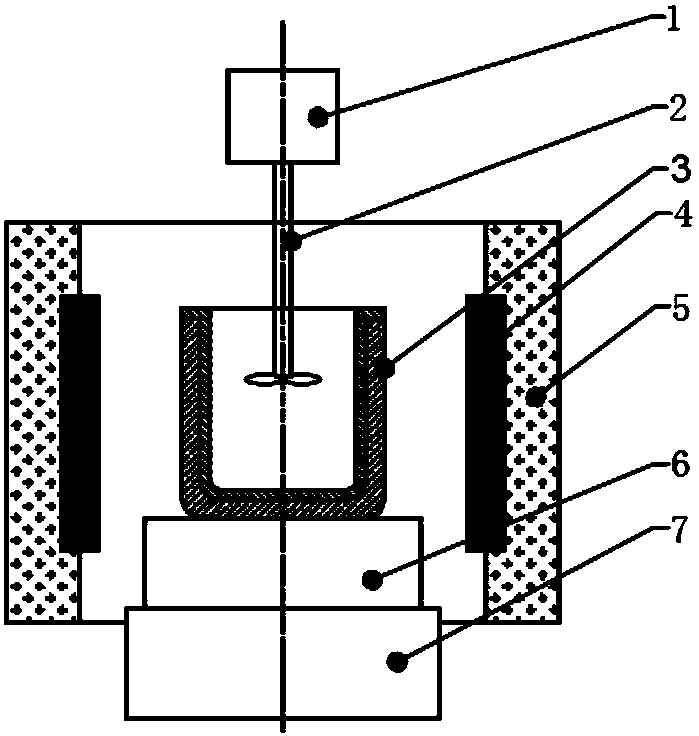

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0015] The laboratory pours the weighed batch materials into the melting sample crucible 3. The crucible is made of two kinds of materials, the inner and outer materials. The inner material is made of precious metal platinum or platinum-rhodium alloy. The clarification temperature is close to 1700°C, and the melting point of pure platinum is 1768°C, so pure platinum or platinum-rhodium alloy materials are used as the inner wall of the crucible to ensure the needs of glass melting samples. The outer layer of the crucible is wrapped with high-temperature resistant ceramic fiber cotton, which can prevent platinum or platinum-rhodium alloy from being oxidized when exposed to air. At the same time, it also plays a role of heat preservation, support and insulation for the crucible, prolonging the service life of the crucible. The crucible with the batch material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com