Preparation method of foam type biomaterial film

A biomaterial and foam technology, applied in the field of biomaterial films, can solve the problems of reducing postoperative complications, inconvenient tissue repair, accelerating wound healing, etc., achieving the effects of scientific and reasonable preparation method, control of wound bleeding, and strong plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

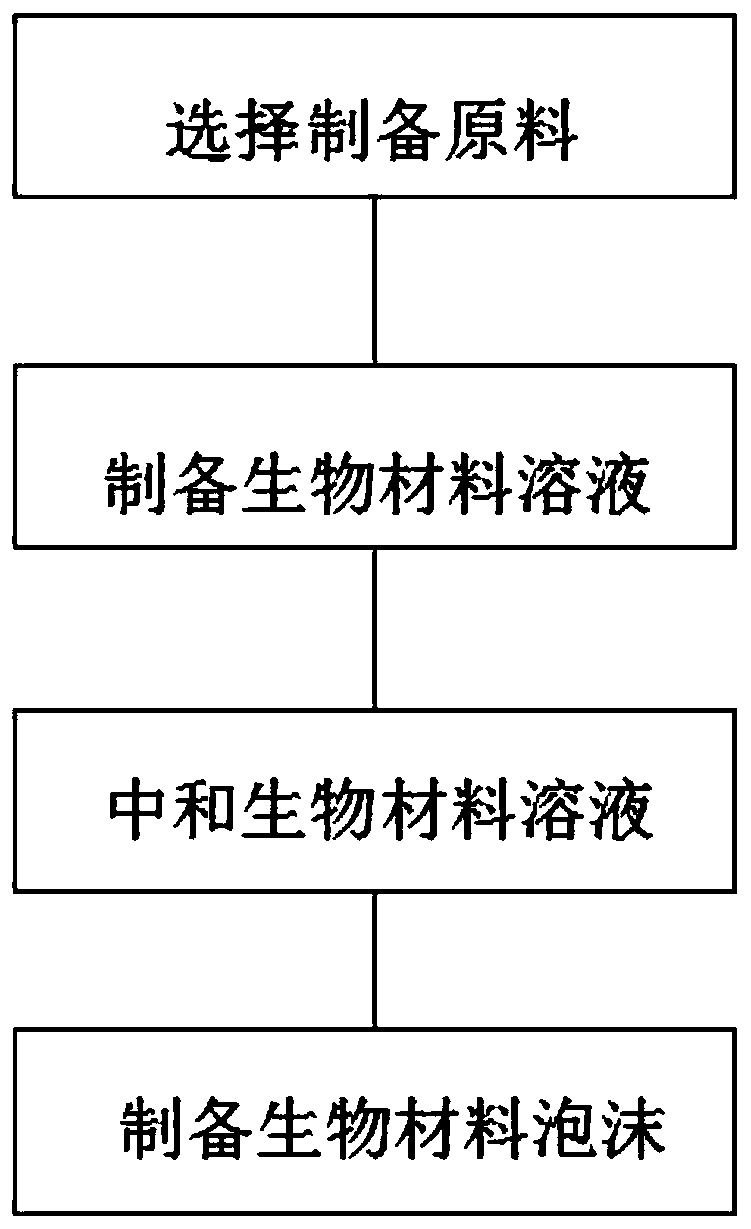

[0021] The invention provides a technical solution: a method for preparing a foam biomaterial film, comprising the following steps:

[0022] S1: Select the preparation material, the preparation material is biological material, liquid and gas, the liquid is water and phosphate buffer solution, the biological material includes collagen, hyaluronic acid, gelatin, butyl polyester, alginate and histone Several, the gas is one of non-toxic gases such as air, oxygen, nitrogen and carbon dioxide, and the effect of carbon dioxide is the best;

[0023] S2: preparing a biological material solution, mixing and stirring the biological material and the HCL solution until the mixture is stirred into uniform biological material solutions of different concentrations for later use;

[0024] S3: Neutralize the biological material solution, take a suitable size dialysis bag and boil it in water for one minute, seal one end of the dialysis bag, move the dialysis bag to the sterile operating table,...

Embodiment 2

[0028] The invention provides a technical solution: a method for preparing a foam biomaterial film, comprising the following steps:

[0029] S1: Select the preparation material, the preparation material is biological material, liquid and gas, the liquid is water and phosphate buffer solution, the biological material includes collagen, hyaluronic acid, gelatin, butyl polyester, alginate and histone Several, the gas is one of non-toxic gases such as air, oxygen, nitrogen and carbon dioxide, and the effect of carbon dioxide is the best;

[0030] S2: preparing a biological material solution, mixing and stirring the biological material and the HCL solution until the mixture is stirred into uniform biological material solutions of different concentrations for later use;

[0031] S3: Neutralize the biological material solution, take a suitable size dialysis bag and boil it in water for one minute, seal one end of the dialysis bag, move the dialysis bag to the sterile operating table,...

Embodiment 3

[0035] The invention provides a technical solution: a method for preparing a foam biomaterial film, comprising the following steps:

[0036] S1: Select the preparation material, the preparation material is biological material, liquid and gas, the liquid is water and phosphate buffer solution, the biological material includes collagen, hyaluronic acid, gelatin, butyl polyester, alginate and histone Several, the gas is one of non-toxic gases such as air, oxygen, nitrogen and carbon dioxide, and the effect of carbon dioxide is the best;

[0037] S2: preparing a biological material solution, mixing and stirring the biological material and the HCL solution until the mixture is stirred into uniform biological material solutions of different concentrations for later use;

[0038] S3: Neutralize the biological material solution, take a suitable size dialysis bag and boil it in water for one minute, seal one end of the dialysis bag, move the dialysis bag to the sterile operating table,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com