Technical method of novel root resisting copper mold based electrolytic copper foil

A technology of electrolytic copper foil and process method, applied in the direction of electrolysis process and electroforming, can solve the problems of plant root tip penetration, building body damage, failure, etc., and achieve the effect of uniform crystal structure and neat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

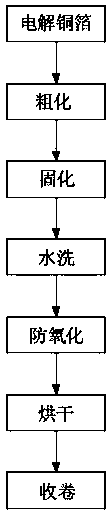

[0026] see figure 1 , the present invention provides a technical solution: a process method of electrolytic copper foil with a new type of root-blocking copper base, which is characterized in that it includes the following steps: the electrolyte is prepared by adding 99% cathode copper plate, sulfuric acid and deionized water to a copper-dissolving tank In the process, under the constant temperature condition of 55 degrees, oxygen is continuously blown into the copper melting tank through the blower, and the copper sulfate aqueous solution is finally obtained through the oxidation reaction process. In the production process of copper foil, the electrolyte is recycled, and the electrolytic copper is continuously precipitated from the titanium roller, thereby continuously consuming the copper in the electrolyte, and the copper in the electrolyte is continuously dissolved by the copper melting tank to replenish the copper consumed in the electrolyte. Keep the copper content in th...

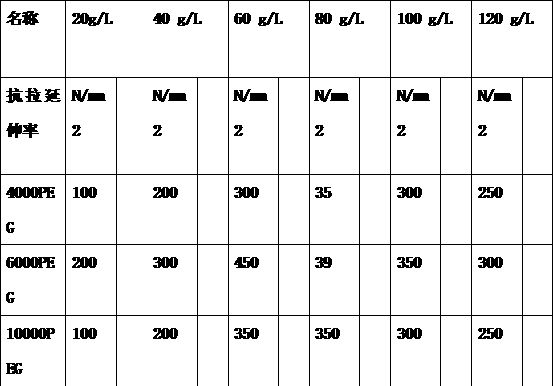

Embodiment 2

[0028] A new type of process method for root-blocking copper base electrolytic copper foil, which is characterized in that it includes the following steps: the electrolyte is prepared by adding 99% cathode copper plate, sulfuric acid and deionized water into a copper-dissolving tank, and the temperature is 55 degrees. Under certain conditions, oxygen is continuously blown into the copper melting tank through a blower, and through an oxidation reaction process, an aqueous solution of copper sulfate is finally obtained. In the production process of copper foil, the electrolyte is recycled, and the electrolytic copper is continuously precipitated from the titanium roller, thereby continuously consuming the copper in the electrolyte, and the copper in the electrolyte is continuously dissolved by the copper melting tank to replenish the copper consumed in the electrolyte. Keep the copper content in the electrolyte in balance at all times. In the process of electrolyte preparation, ...

Embodiment 3

[0030]A new type of process method for root-blocking copper base electrolytic copper foil, which is characterized in that it includes the following steps: the electrolyte is prepared by adding 99% cathode copper plate, sulfuric acid and deionized water into a copper-dissolving tank, and the temperature is 55 degrees. Under certain conditions, oxygen is continuously blown into the copper melting tank through a blower, and through an oxidation reaction process, an aqueous solution of copper sulfate is finally obtained. In the production process of copper foil, the electrolyte is recycled, and the electrolytic copper is continuously precipitated from the titanium roller, thereby continuously consuming the copper in the electrolyte, and the copper in the electrolyte is continuously dissolved by the copper melting tank to replenish the copper consumed in the electrolyte. Keep the copper content in the electrolyte in balance at all times. In the process of electrolyte preparation, n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com