Preparation method of tunneling oxidation passivation PERC battery with selective contact with emitter junction

A technology of tunneling oxidation and tunneling oxide layer is applied in the field of tunneling oxidation passivation PERC battery preparation to achieve the effect of improving battery Voc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

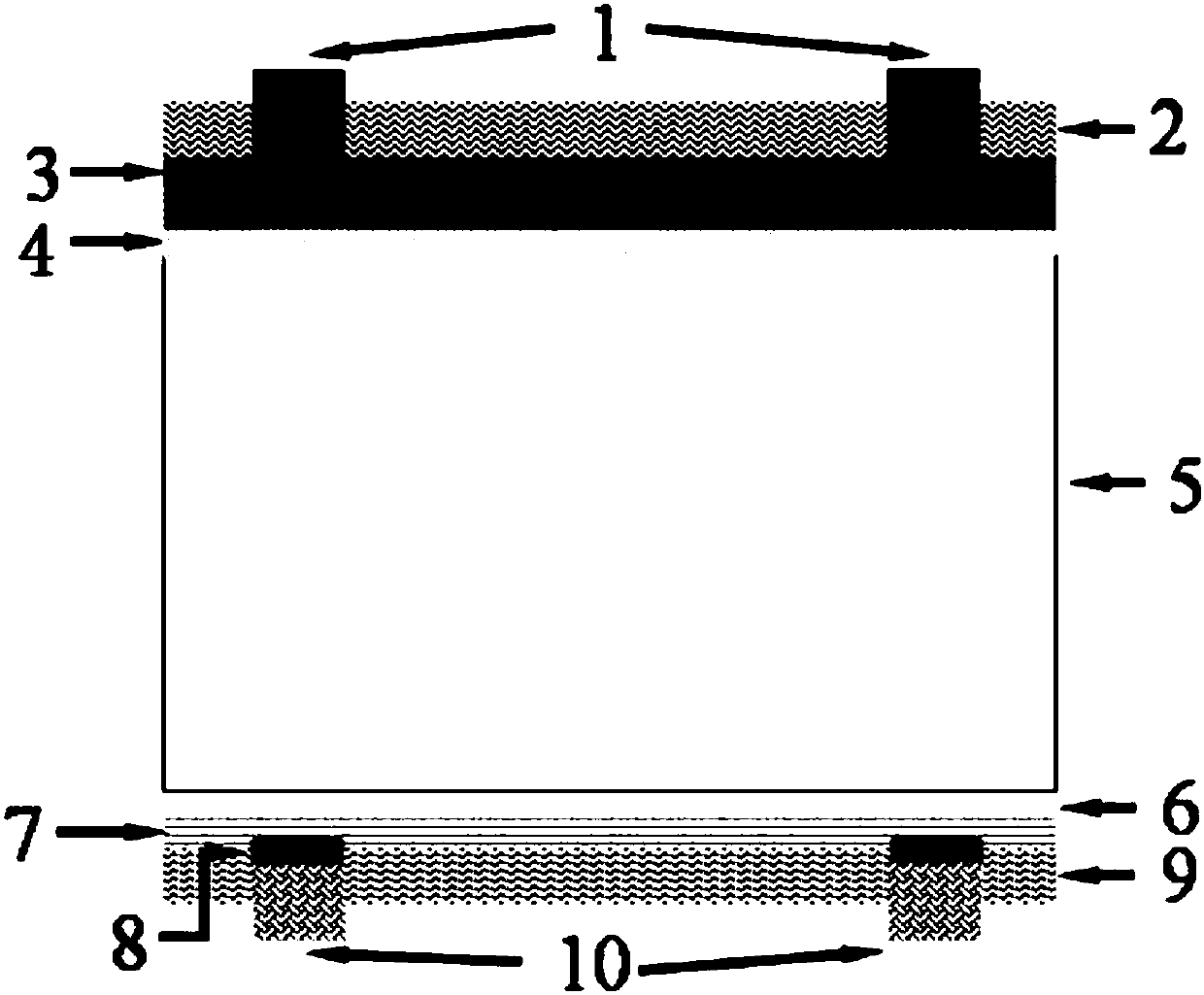

[0034] A tunnel oxidation passivation PERC cell with selective contact of the emitter junction (such as figure 1 The preparation method shown) adopts the following steps:

[0035] (1) The silicon wafer 1 (P-type silicon wafer in this embodiment) is removed from the damaged layer in an alkali texturing tank, the surface is polished, and the front side texturing is performed to form a 1-6μm high pyramid suede (in this embodiment 3μm high pyramid suede), that is, suede made of silicon wafer.

[0036] (2) Use wet chemical or high temperature thermal oxidation method to prepare tunnel oxide layer SiO on silicon wafer texture 2 4. The thickness is 0.5nm-2nm, and the CVD method is used to deposit the thickness of 10nm-500nm on the front surface of the silicon wafer 5, and the P atom content is 1×10 19 cm -3 -1×10 21 cm -3 的P-doped polysilicon layer 3;

[0037] Specifically in this embodiment, the tunneling oxide layer SiO 2 4 is the ultra-thin tunneling oxide layer SiO 2 , Thickness 1.8-2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com