Water-based high-solid-content damping rubber and preparation method thereof

A technology of high solid content and shock-absorbing adhesive, applied in non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve the problems of difficult qualification and high product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

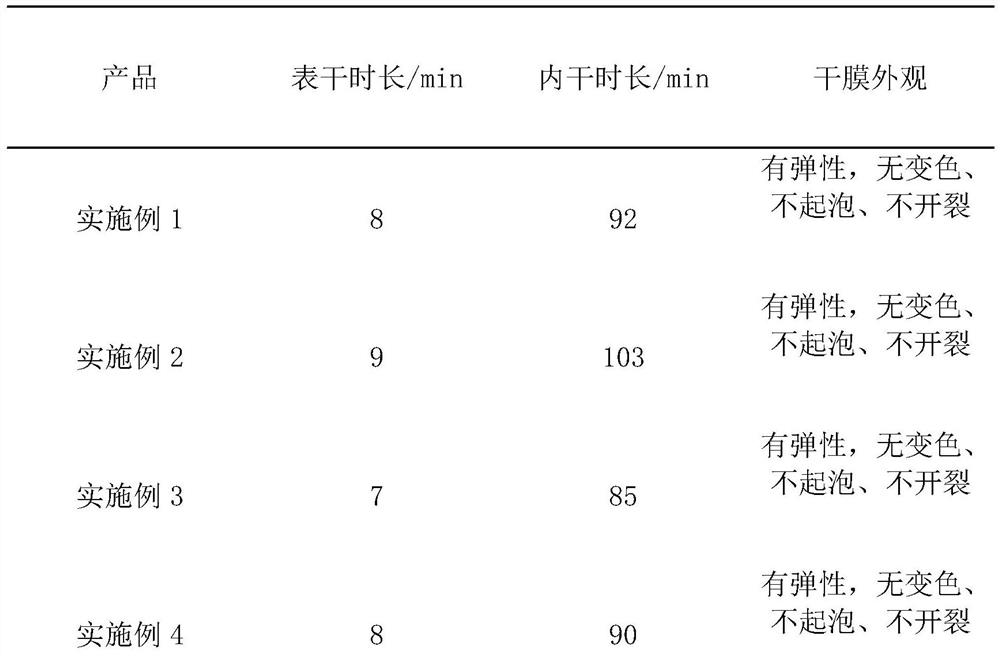

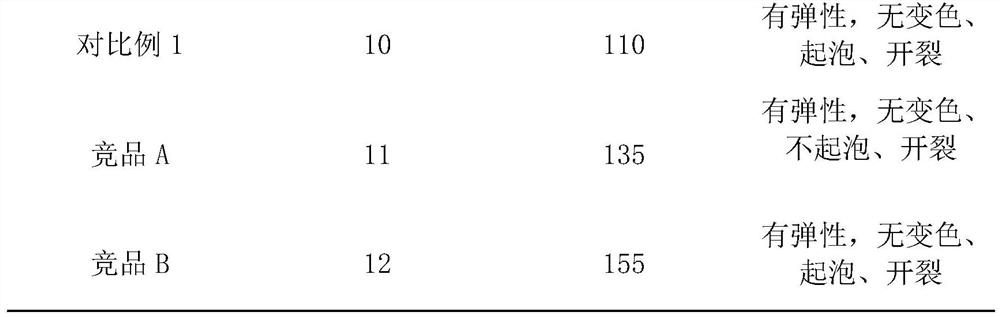

Examples

Embodiment 1

[0037] Embodiment 1: 20% of styrene-acrylic emulsion, 12% of pure acrylic emulsion, 65% of functional powder, and 3% of functional auxiliary agent; wherein the functional powder includes specific components and percentages: talcum powder 20, zinc phosphate 10, carbon black 1, Microsilica powder 4, mica powder 25, mineral fiber 2, modified synthetic fiber 3; functional additives specifically include the specific components and percentages: anti-flash rust agent 1, foam inhibitor 0.3, wetting and dispersing agent 0.2, pH regulator 0.5, rheology additive 0.5.

Embodiment 2

[0038] Example 2: styrene-acrylic emulsion 25, pure acrylic emulsion 20, functional powder 52, functional additive 3; wherein the functional powder includes specific components and percentages: talcum powder 20, carbon black 1, silicon micropowder 4, mica powder 20 , zinc phosphate 5, mineral fiber 1, modified synthetic fiber 1; functional additives include specific components and percentages: anti-flash rust agent 1.5, foam inhibitor 0.2, wetting and dispersing agent 0.2, PH value regulator 0.5, rheology Auxiliary 0.6.

Embodiment 3

[0039]Example 3: styrene-acrylic emulsion 30, pure acrylic emulsion 13, functional powder 47, functional auxiliary agent 10; wherein the functional powder includes specific components and percentages: hollow glass beads 20, carbon black 1, silicon micropowder 4, mica powder 15. Zinc phosphate 5, mineral fiber 1, modified plant fiber 1; functional additives include specific components and percentages: anti-flash rust agent 3.5, foam suppressor 0.8, wetting and dispersing agent 0.6, PH value regulator 2.0, fluid Variable additive 2.5, fungicide 0.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Impact | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com