Water-dissolvable rubber material and preparation method thereof

A rubber material and water-contact technology, applied in the field of functional polymer materials, can solve the problems of insolubility and solubility of rubber, and achieve the effects of high economic value and social value, convenient construction and lower project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

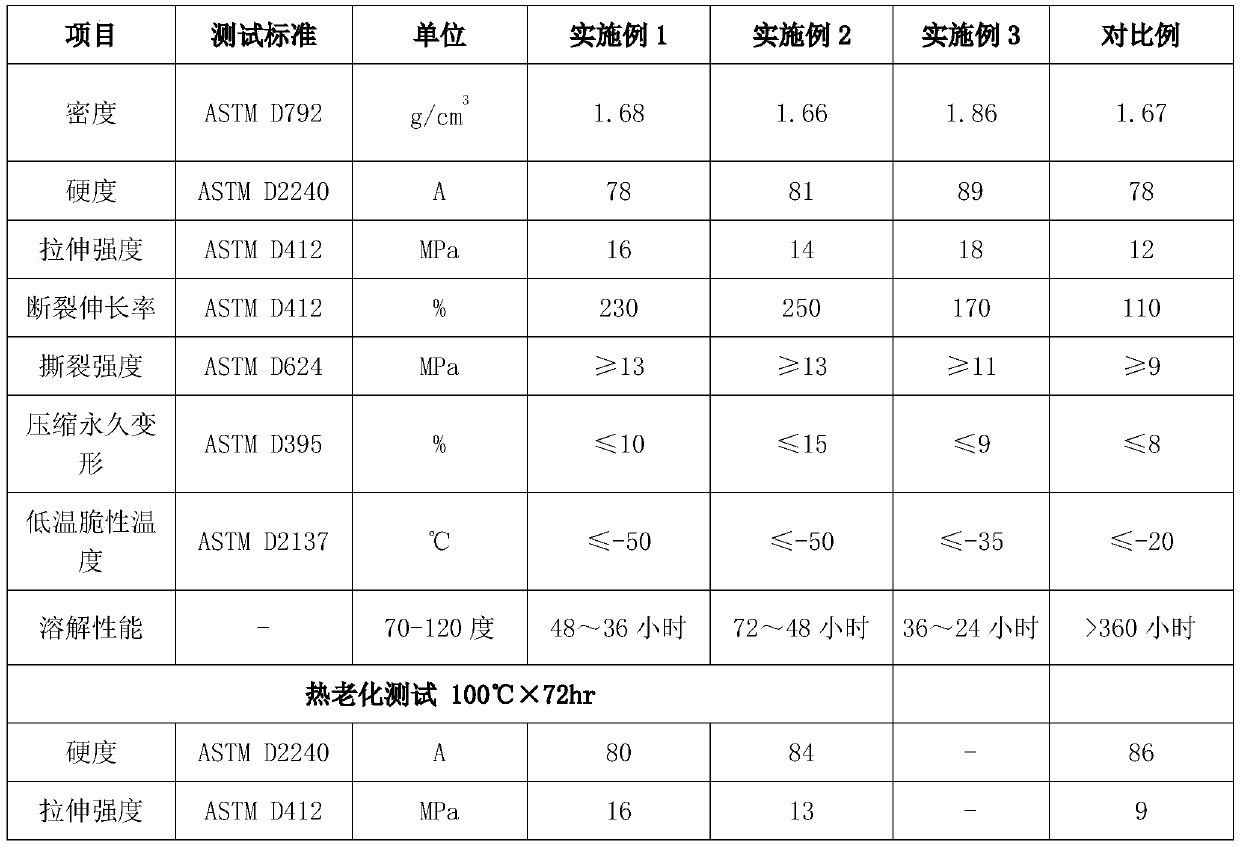

Examples

Embodiment 1

[0030] The present embodiment provides a kind of preparation method of water-soluble rubber, and concrete steps are as follows:

[0031] Step 1: Add 50 parts of dimethylol propionic acid modified polyurethane, 20 parts of ethylenediaminopropanesulfonic acid modified chitosan, polyvinyl alcohol grafted methacrylic acid shrink 15 parts of glyceride, 5 parts of maleic anhydride grafted SBS, 10 parts of carboxymethyl-modified nano-silica, 0.5 parts of coupling agent, 0.5 parts of antioxidant, 2.5 parts of softener, at a blending temperature of 30°C Next, mixed for 30 minutes, left for 30 hours to obtain material 1;

[0032] Step 2: Take the material 1 out of the internal mixer or open mill and enter it into granulation equipment for granulation or into powder milling equipment for grinding into shapes with a particle size of 50-150 mesh. Material 2 was obtained.

[0033] Step 3: Add material 2 to the high-speed mixer at a speed of 400rpm, then add 0.5 parts of crosslinking agent...

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of water-soluble rubber, and concrete steps are as follows:

[0036] Step 1: Add 65 parts of dimethylolpropionic acid modified polyurethane, 15 parts of ethylenediaminopropanesulfonic acid modified chitosan, polyvinyl alcohol grafted methacrylic acid shrink 5 parts of glyceride, 5 parts of maleic anhydride grafted SBS, 10 parts of carboxymethyl-modified nano-silica, 0.5 parts of coupling agent, 0.5 parts of antioxidant, 2.5 parts of softener, at a blending temperature of 30°C Next, mixed for 30 minutes, left for 30 hours to obtain material 1;

[0037] Step 2: Take the material 1 out of the internal mixer or open mill and enter it into granulation equipment for granulation or into powder milling equipment for grinding into shapes with a particle size of 50-150 mesh. Material 2 was obtained.

[0038] Step 3: Add material 2 into a high-speed mixer at a speed of 400rpm, then add 0.5 parts of crosslinking agent, ...

Embodiment 3

[0040]The present embodiment provides a kind of preparation method of water-soluble rubber, and concrete steps are as follows:

[0041] Step 1: Add 20 parts of dimethylol propionic acid modified polyurethane, 25 parts of ethylenediaminopropanesulfonic acid modified chitosan, polyvinyl alcohol grafted methacrylic acid shrink 20 parts of glyceride, 10 parts of maleic anhydride grafted, 20 parts of carboxymethyl-modified nano-silica, 0.8 parts of coupling agent, 0.6 parts of antioxidant, 2.5 parts of softener, at a blending temperature of 30°C , mixed for 30 minutes, and left for 30 hours to obtain material 1;

[0042] Step 2: Take the material 1 out of the internal mixer or open mill and enter it into granulation equipment for granulation or into powder milling equipment for grinding into shapes with a particle size of 50-150 mesh. Material 2 was obtained.

[0043] Step 3: Add material 2 to the high-speed mixer at a speed of 400rpm, then add 0.5 parts of crosslinking agent, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com