Assembled local curved space and repeated rubbing swinging type shock insulation system

A seismic isolation system and prefabricated technology, applied in the direction of earthquake-proof, protective buildings/shelters, building components, etc., can solve the problems of poor durability, easy corrosion of metal, and limited support size, so as to achieve full space utilization and improve Vibration isolation effect, the effect of prolonging the natural vibration period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

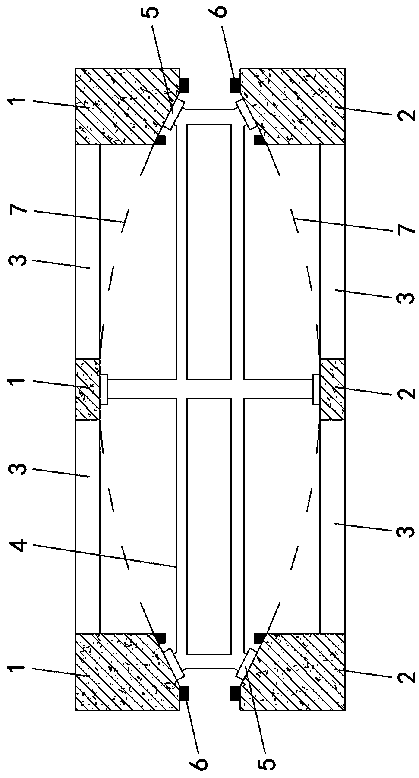

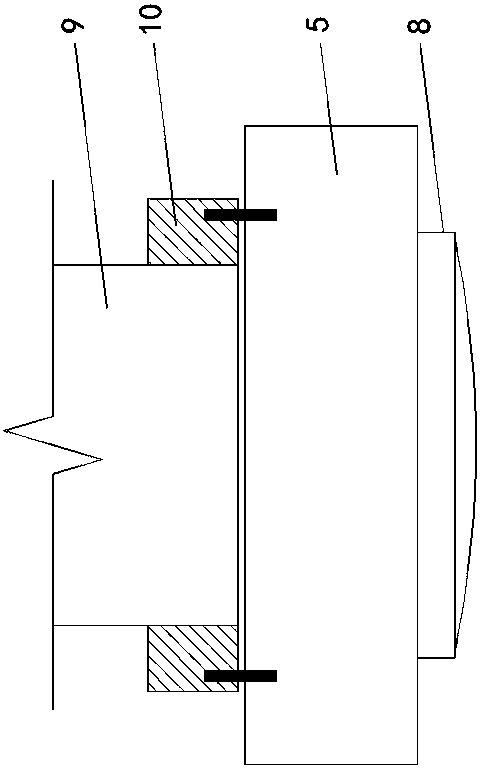

[0016] Specific implementation mode one: as Figure 1~Figure 3 As shown, the present invention discloses a prefabricated partial curved surface space complex friction pendulum type seismic isolation system, including a sliding frame 4 and two groups of seismic isolation piers, and the two groups of seismic isolation piers are reinforced concrete structures or steel pipe concrete structure, two sets of seismic isolation piers are arranged in arrays and divided into an upper seismic isolation pier layer composed of a plurality of upper seismic isolation piers 1 and a lower seismic isolation pier layer composed of a plurality of lower seismic isolation piers 2. The upper surface of the earthquake-isolation pier column layer is arranged flush, and the lower surface of the lower earthquake-isolation pier column layer is arranged flush. The upper seismic isolation pier column 1 and every two adjacent lower seismic isolation pier columns 2 are connected and fixed through the pier col...

specific Embodiment approach 2

[0017] Specific implementation mode two: as figure 1 As shown, this embodiment is a further description of Embodiment 1. The lower end of the upper seismic isolation pier 1 and the upper end of the lower seismic isolation pier 2 located at the edge are fixed with anti-collision limiting piers 6, The anti-collision limiting pier 6 is prefabricated with high ductility fiber concrete, and is fixed with the seismic isolation pier column by embedded parts welding, which has good impact resistance.

specific Embodiment approach 3

[0018] Specific implementation mode three: as figure 1 , 2 As shown, this embodiment is a further description of specific embodiment 1 or specific embodiment 2. The end face of each of the shock-absorbing pier columns on the sliding surface and the contact surface of each of the sliding column caps 5 are set There is a wear-resistant layer, and the wear-resistant layer is made of low-friction material (friction coefficient less than 0.15), preferably polytetrafluoroethylene material, and the end surface of the shock-isolation pier on the sliding surface and the contact surface of the sliding column cap 5 are dipped and polished to meet After request, the wear-resistant layer is made by spraying or pasting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com