Natural gas storing-transporting-utilizing integrated device based on hydrate technology

A natural gas and hydrate technology, applied in transportation and packaging, gas/liquid distribution and storage, liquid bottling, etc., can solve the lack of natural gas transportation and replenishment devices, additional heat injection for hydrate decomposition, and long hydrate formation cycle and other problems, to achieve rapid cooling, increase storage capacity, and increase the effect of gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

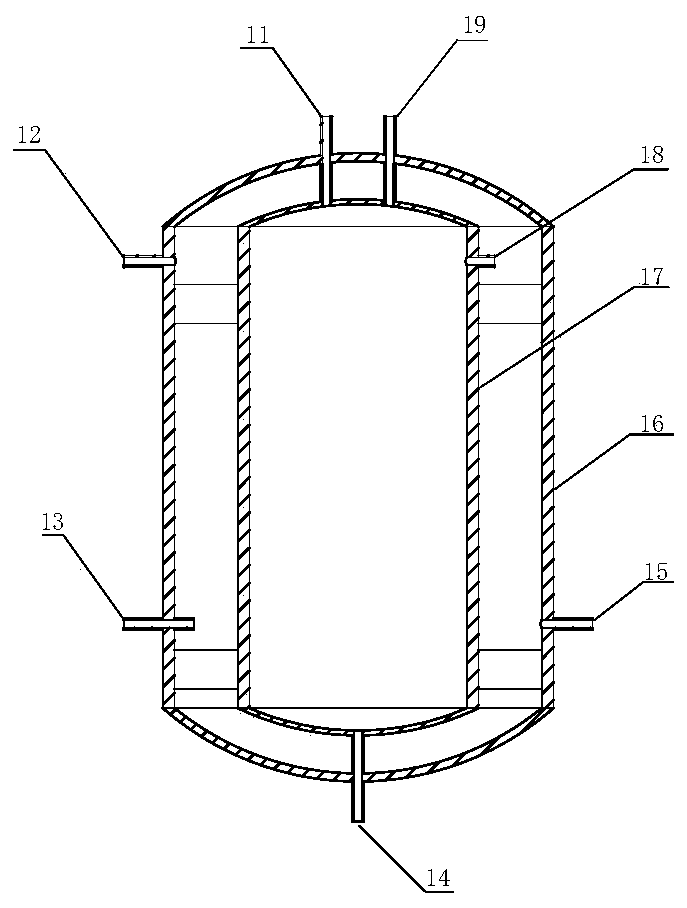

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

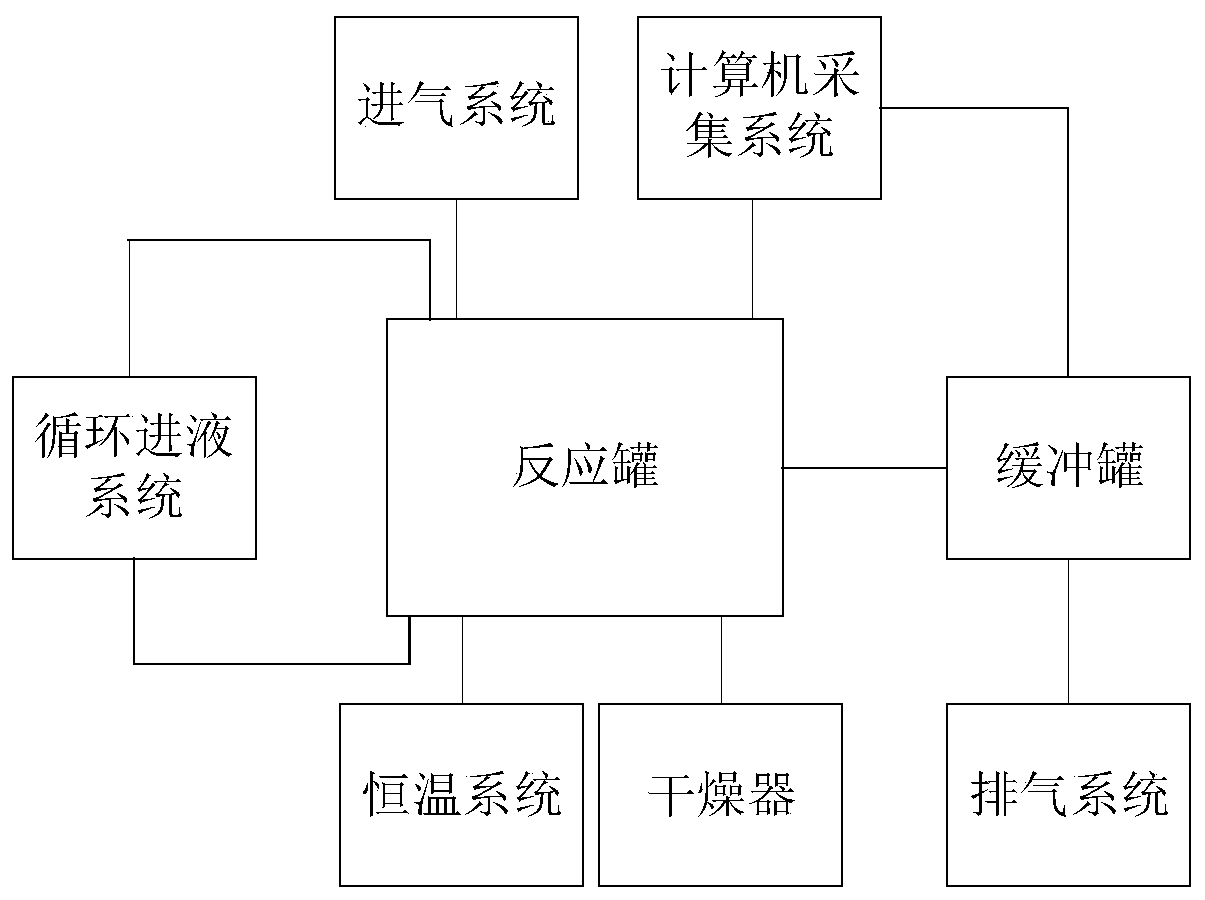

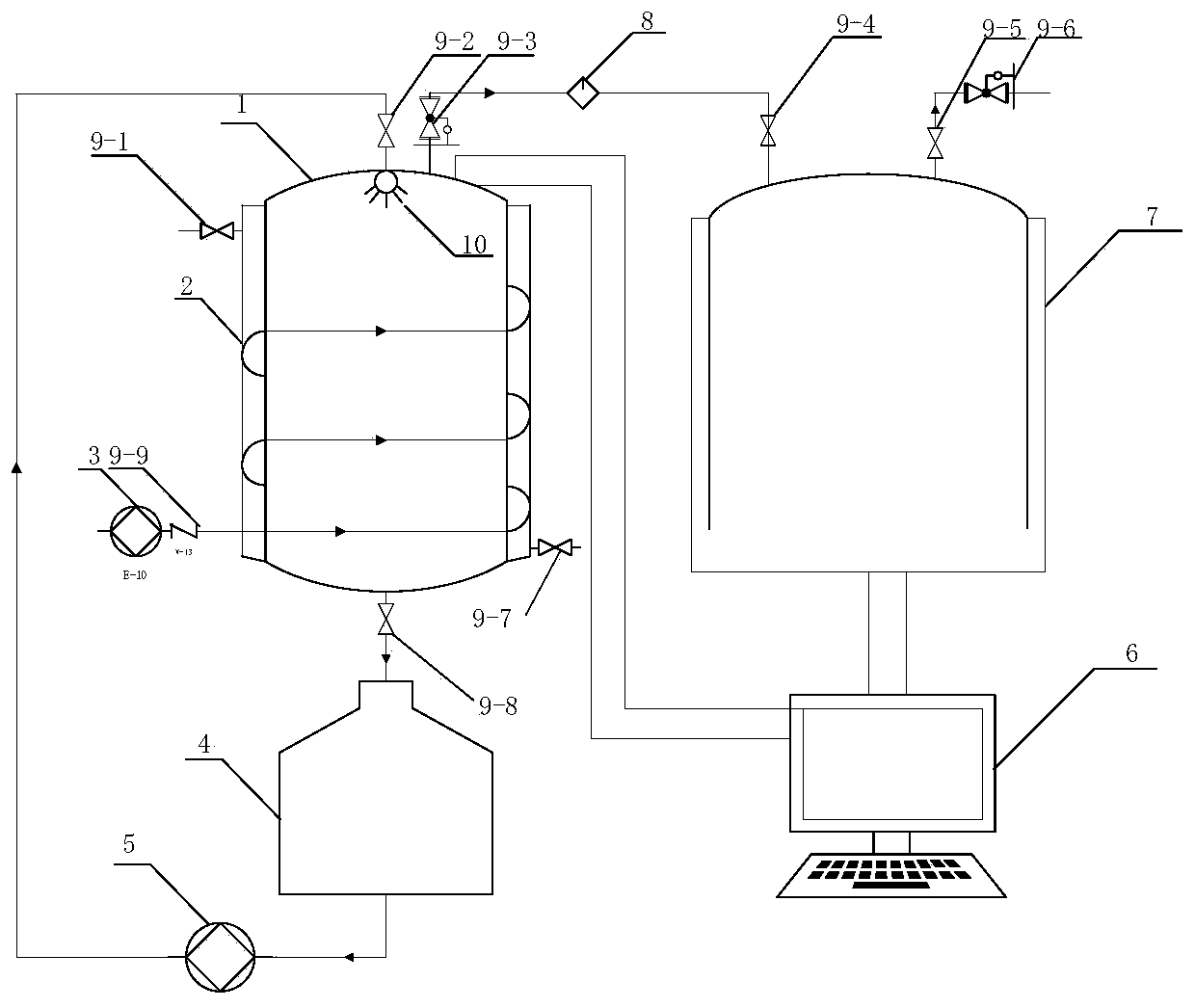

[0021] figure 1 Shown is a block diagram of the working principle of a natural gas storage-transportation-utilization integrated device based on hydrate technology. It enters the reaction tank through the air intake system, and the heat exchange system fully recovers its cooling capacity. The water is atomized in the reaction tank through the circulating liquid inlet system, and the conditions of low temperature and high pressure are maintained under the operation of the heat exchange system to generate natural gas hydrate. When gas is needed, use the decompression principle to decompose hydrate. The decomposed gas enters the buffer tank after being dried by the dryer. The outlet pressure of the buffer tank is adjusted by the exhaust system, which is convenient for connecting to other gas-using devices. The signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com