Method for carrying out collaborative incineration treatment on semi-dry sludge and garbage

A semi-dry sludge and garbage incineration technology, which is applied in dehydration/drying/concentrated sludge treatment, combustion methods, incinerators, etc., can solve the problem of increased sludge landfill costs, increased farmland heavy metal concentration, and sludge landfill space Reduction and other issues, to achieve the effect of reducing volume, reducing equipment investment and operating costs, and achieving harmlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the example of the present invention is described in detail:

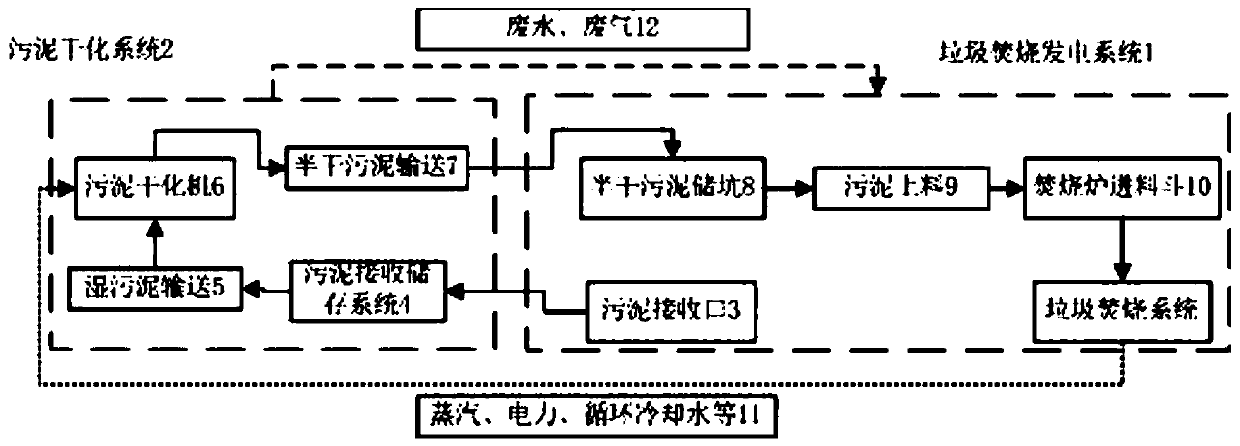

[0032] Such as figure 1 As shown, the reference signs in the drawings of the specification include: waste incineration power generation system 1, sludge drying system 2, sludge receiving port 3, sludge receiving and storage system 4, wet sludge conveying system 5, sludge drying Machine 6, semi-dry sludge transportation 7, semi-dry sludge storage pit 8, sludge feeding system 9, incinerator feed hopper 10, steam\electricity\circulating cooling water and other public systems 11, sludge drying wastewater\ Exhaust gas collection system 12.

[0033] A specific case implementation process of a method for co-incineration of sludge and domestic waste:

[0034] The wet sludge is transported by the sludge truck from the sewage plant into the waste incineration power plant area, enters the garbage unloading hall, and discharges the wet sludge into the sludge receiving an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com