Method for testing mixing uniformity of positive electrode materials of lithium battery

A technology of mixing uniformity and positive electrode material, which is applied in the field of testing the mixing uniformity of positive electrode materials of lithium batteries, can solve the problems of complex test process and insufficient accuracy, and achieve the effect of simple test process and high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

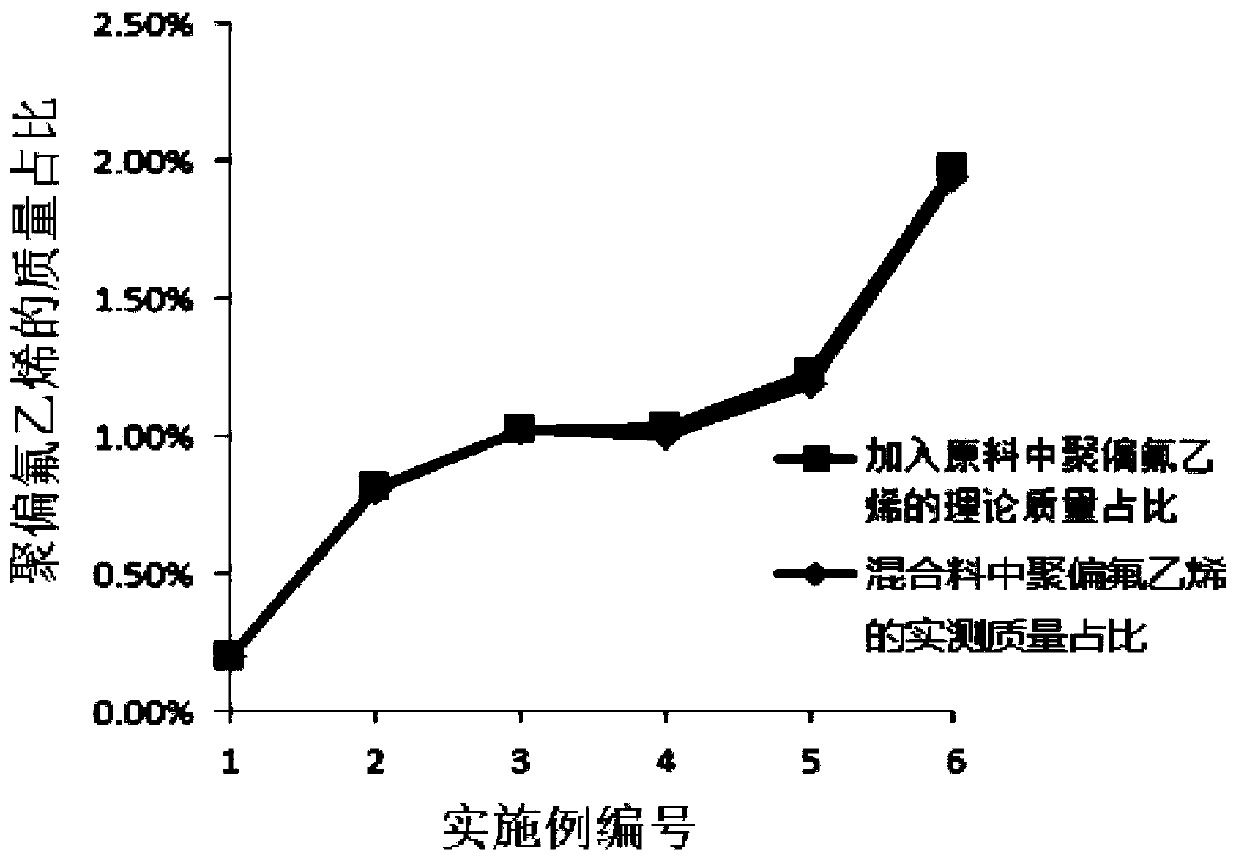

Embodiment 1

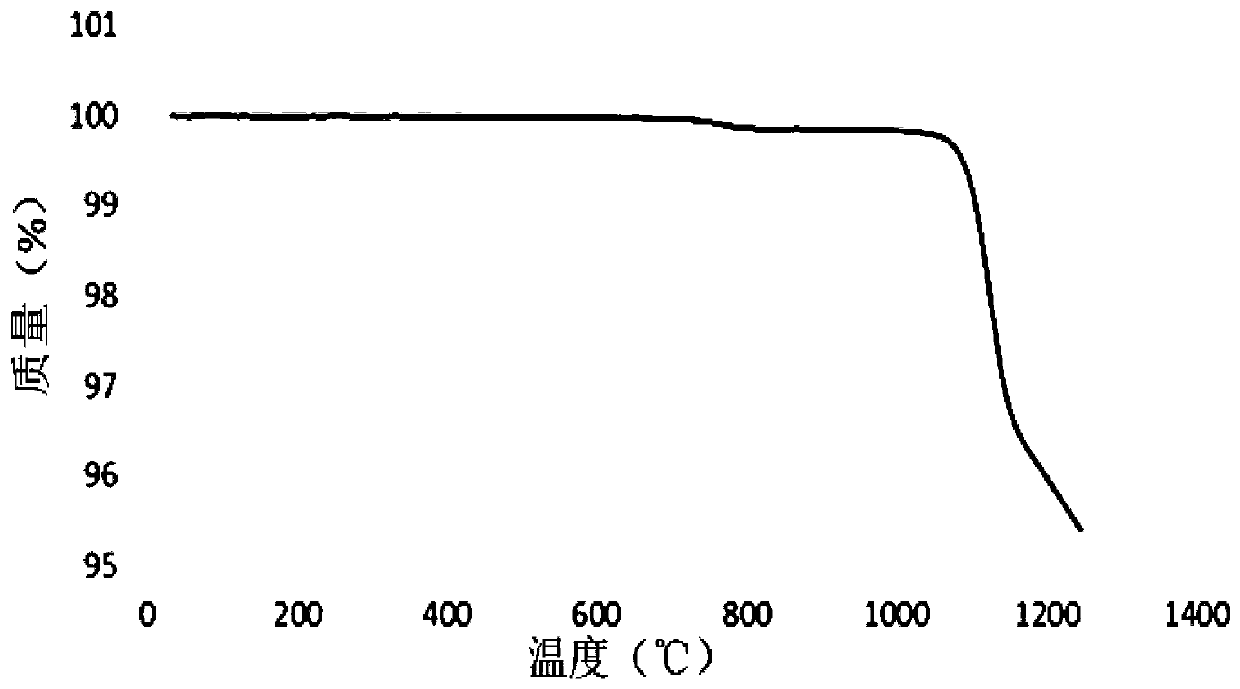

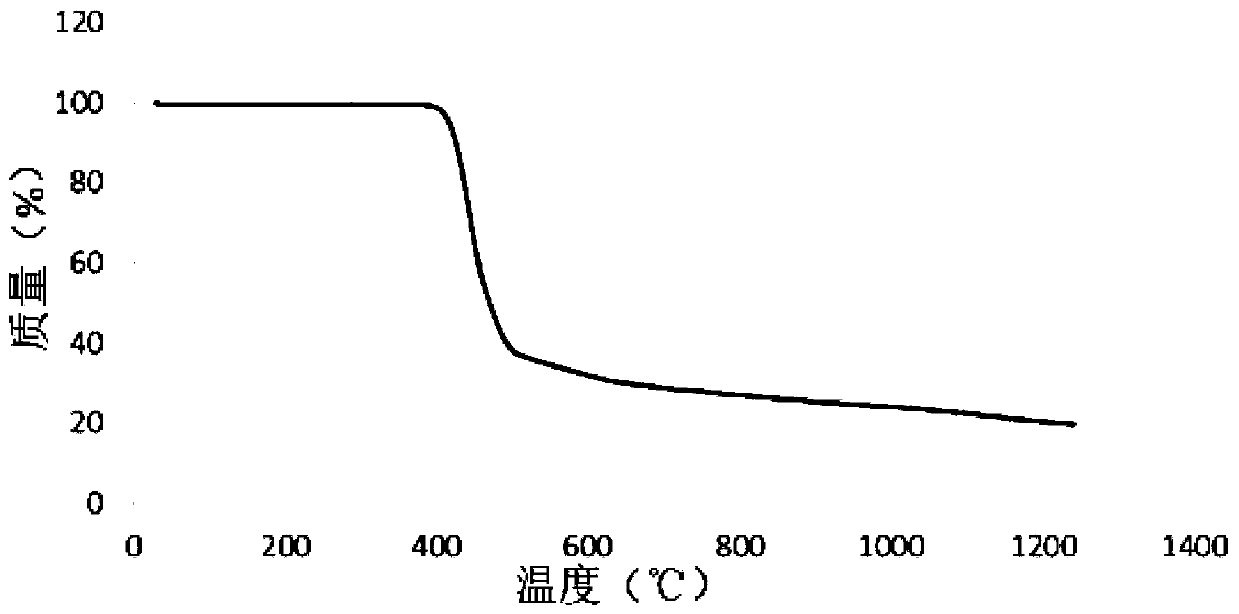

[0054] (1) The test method for the volatility of polyvinylidene fluoride under the theoretical ratio is to weigh the theoretical ratio of lithium cobaltate and polyvinylidene fluoride into the crucible without mixing, heat treatment at 600 ° C for 3 hours, and weigh the residual mass m 残 , calculate the volatilization rate V of polyvinylidene fluoride, the calculation formula is as follows:

[0055]

[0056] Repeat the above steps for 3 times and take the average value to obtain the volatilization rate of polyvinylidene fluoride under the theoretical ratio;

[0057] (2) Lithium cobalt oxide with a theoretical mass ratio of 99.8% and polyvinylidene fluoride with a theoretical mass ratio of 0.2% are mixed to obtain a mixture;

[0058] (3) The mixture obtained in step (2) is heat-treated at 600°C for 3 hours, and the residual amount M of the sample after heat treatment is weighed R , and calculate the measured mass ratio C of polyvinylidene fluoride in the mixture in conjunc...

Embodiment 2

[0061] (1) The volatility test method of the polyvinylidene fluoride under the theoretical proportion is the same as that of Example 1;

[0062] (2) Lithium cobalt oxide with a theoretical mass ratio of 99.19% and polyvinylidene fluoride with a theoretical mass ratio of 0.81% are mixed to obtain a mixture;

[0063] (3) The measured mass ratio of polyvinylidene fluoride in the mixture is C p The test calculation method is exactly the same as that of Example 1.

Embodiment 3

[0065] (1) The volatility test method of the polyvinylidene fluoride under the theoretical proportion is the same as that of Example 1;

[0066] (2) Lithium cobalt oxide with a theoretical mass ratio of 98.98% and polyvinylidene fluoride with a theoretical mass ratio of 1.02% are mixed to obtain a mixture;

[0067] (3) The measured mass ratio of polyvinylidene fluoride in the mixture is C p The test calculation method is exactly the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com