Method for preparing rice straw feed

A technology of rice straw and feed, which is applied in the field of preparing rice straw feed, can solve the problems of spoilage and deterioration, the effect of inhibition is not obvious, and is rarely used, and achieves the effects of low cost, obvious effect of weight gain, and improvement of immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

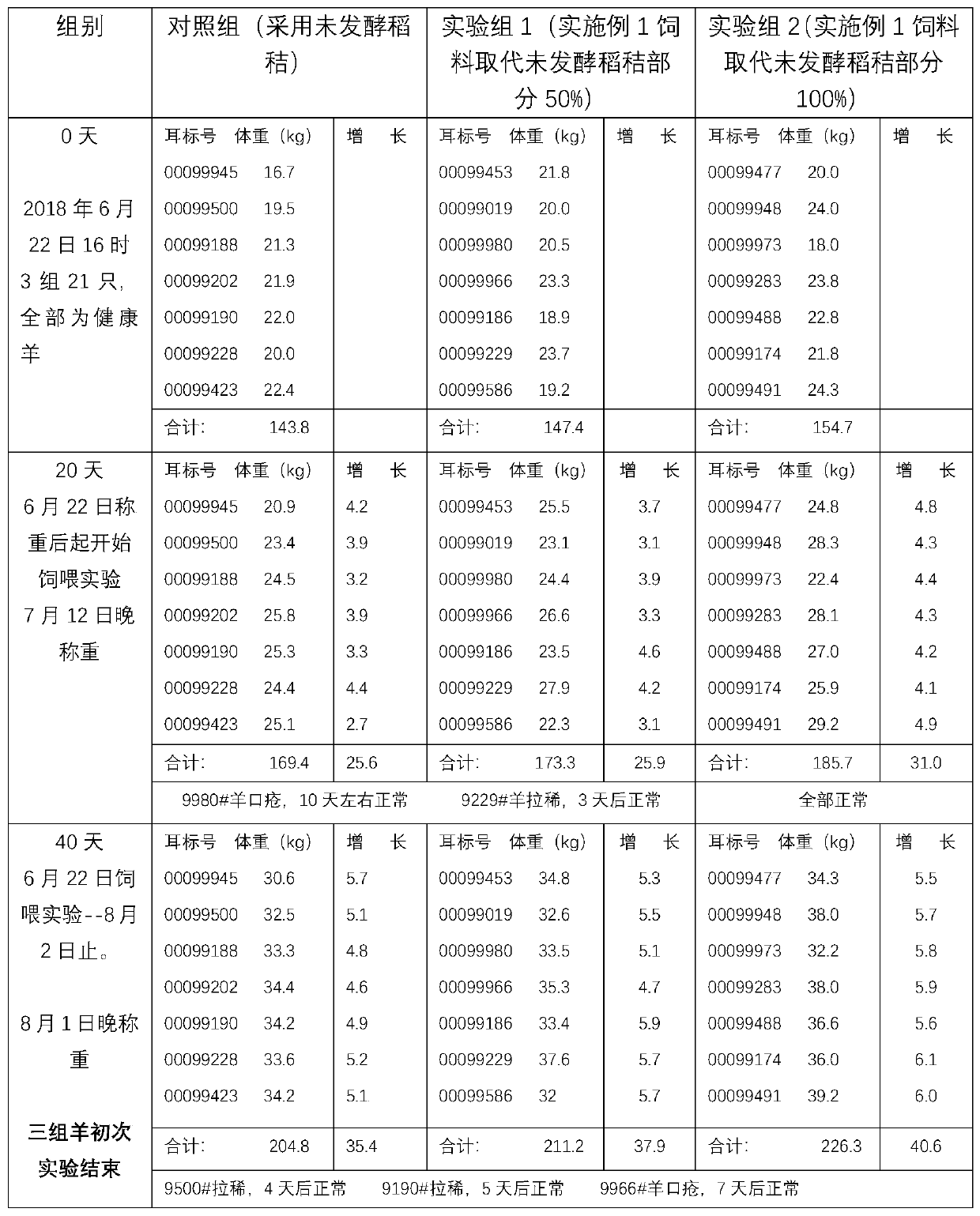

Examples

Embodiment 1

[0027] A method for preparing rice straw feed, comprising the following steps:

[0028] A. Cut the rice stalks into 3-6cm segmental stalks for later use;

[0029] B. After diluting the cellulase and the lactic acid bacteria group with water respectively, mix them in proportion, and then spray them on the surface of the segmented straw with an agricultural electric sprayer, and stir and mix evenly;

[0030] C. Compact the section-shaped straw and use a fully automatic baling and wrapping machine to wrap the film on the periphery of the section-shaped straw to isolate it from the air, and seal it for storage;

[0031] D. After storage for 95 days, rice straw feed can be obtained.

[0032] The lactic acid bacteria group includes Lactobacillus panis (Lactobacillus bread) and Lactobacillus plantarum (Lactobacillus plantarum), and the mass ratio is 1:1.

[0033] The cellulase solution is 75 FPU / ml.

[0034] The mass volume ratio of the straw to the cellulase solution is 3g:1.5mL....

Embodiment 2

[0040] A method for preparing rice straw feed, comprising the following steps:

[0041] A. Cut the rice stalks into 3-6cm segmental stalks for later use;

[0042] B. After diluting the cellulase and the lactic acid bacteria group with water respectively, mix them in proportion, and then spray them on the surface of the segmented straw with an agricultural electric sprayer, and stir and mix evenly;

[0043] C. Compact the section-shaped straw and use a fully automatic baling and wrapping machine to wrap the film on the periphery of the section-shaped straw to isolate it from the air, and seal it for storage;

[0044] D. After storage for 90 days, rice straw feed can be obtained.

[0045]The lactic acid bacteria group includes Lactobacillus panis (Lactobacillus bread) and Lactobacillus plantarum (Lactobacillus plantarum), with a mass ratio of 1:3.

[0046] The cellulase solution is 60 FPU / ml.

[0047] The mass volume ratio of the straw to the cellulase solution is 1g:2.5mL. ...

Embodiment 3

[0053] A method for preparing rice straw feed, comprising the following steps:

[0054] A. Cut the rice stalks into 3-6cm segmental stalks for later use;

[0055] B. After diluting the cellulase and the lactic acid bacteria group with water respectively, mix them in proportion, and then spray them on the surface of the segmented straw with an agricultural electric sprayer, and stir and mix evenly;

[0056] C. Compact the section-shaped straw and use a fully automatic baling and wrapping machine to wrap the film on the periphery of the section-shaped straw to isolate it from the air, and seal it for storage;

[0057] D. After storage for 120 days, rice straw feed can be obtained.

[0058] The lactic acid bacteria group includes Lactobacillus panis (Lactobacillus bread) and Lactobacillus plantarum (Lactobacillus plantarum), and the mass ratio is 4:1.

[0059] The cellulase solution is 80 FPU / ml.

[0060] The mass volume ratio of the straw to the cellulase solution is 5g:0.5mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com