Flavor steamed bread processing technology

A processing technology and technology of steamed buns, which is applied in the field of flavored steamed buns processing technology, can solve the problems of steamed buns being inedible, pressed into dead noodles, and smaller in size, so as to increase the flavor and taste, reduce the amount of addition, and increase the dough speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

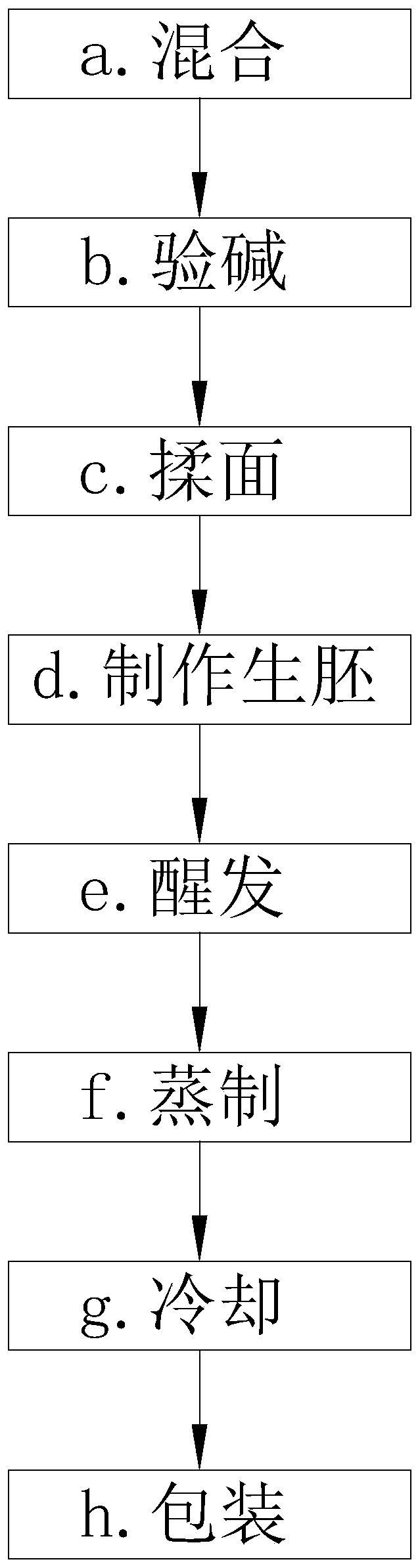

[0040] Such as figure 1 Shown, a kind of flavor steamed bread processing technology comprises the following steps:

[0041] a. Mixing: Mix 20-22kg old flour fertilizer, 140-150g edible alkali, 225-250g salt, 20-25kg water, 175g-200g fresh yeast and 45-50kg flour, then add flour and stir for 15 minutes;

[0042] b. Alkali test: take out a small sample for alkali test, put the small sample in a steamer for 3-5 minutes, take it out, and judge whether it is qualified according to the color and fragrance;

[0043] c. Knead the dough: After the sample is qualified, continue to stir the raw materials for 5 minutes, then divide the dough into 12-14kg balls, put them into the kneading machine and knead the dough, and spread it on the operating table after kneading;

[0044] d. Making raw embryos: Knead 110g-112g of dough and dough to make raw embryos, and arrange th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com