Low-temperature curing method for glass ceramic silver-coating silica gel

A glass-ceramic and curing method technology, applied in radioactive purification, nuclear engineering and other directions, can solve problems such as the inability to handle radioactive iodine for a long time, the deformation of the solidified body affects the stability, etc., and achieves good industrial application prospects, low iodine leaching rate, solidification low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] In this example, the common iodine-127 is used to simulate the radionuclide iodine-129. A low-temperature curing method for glass ceramics coated with silver silica gel, comprising the following steps:

[0087] (1) 0.916gSiO 2 , 2.272gB 2 o 3 , 1.694gBi 2 o 3 , 1.118g ZnO was added with deionized water and placed in a colloid mill for 24 hours, then evaporated and dried at 100°C for 6 hours to obtain a glass-ceramic sintered substrate, and the glass-ceramic sintered substrate was placed in a high-temperature muffle furnace, Sintering to obtain glass-ceramic, put glass-ceramic into agate mortar and grind to obtain glass-ceramic powder;

[0088] (2) Add deionized water to the obtained glass ceramic powder, 2.518g silica gel and 1.482g AgI, put it in a colloid mill and grind it thoroughly for 24 hours, then evaporate and dry at 100°C for 6 hours to obtain a dried mixture;

[0089] (3) The dry mixture is pre-pressed at 10MPa to obtain a block-shaped dry mixture;

[0...

Embodiment 2

[0093] In this example, the common iodine-127 is used to simulate the radionuclide iodine-129. A low-temperature curing method for glass ceramics coated with silver silica gel, comprising the following steps:

[0094] (1) 1.782gSiO 2 , 0.448gB 2 o 3 , 2.272gBi 2 o 3 , 1.498g of ZnO was added with deionized water and placed in a colloid mill for 24 hours and then evaporated and dried at 100°C for 6 hours to obtain a glass-ceramic sintered substrate. Put the glass-ceramic sintered substrate into a high-temperature muffle furnace, Sintering to obtain glass-ceramic, put glass-ceramic into agate mortar and grind to obtain glass-ceramic powder;

[0095] (2) Add the obtained glass ceramic powder, 2.518g of silica gel and 1.482g of AgI into deionized water, place it in a colloid mill and grind it thoroughly for 30 hours, then evaporate and dry at 100°C for 6 hours to obtain a dry mixture;

[0096] (3) The dry mixture is pre-pressed at 10MPa to obtain a block-like dry mixture;

...

Embodiment 3

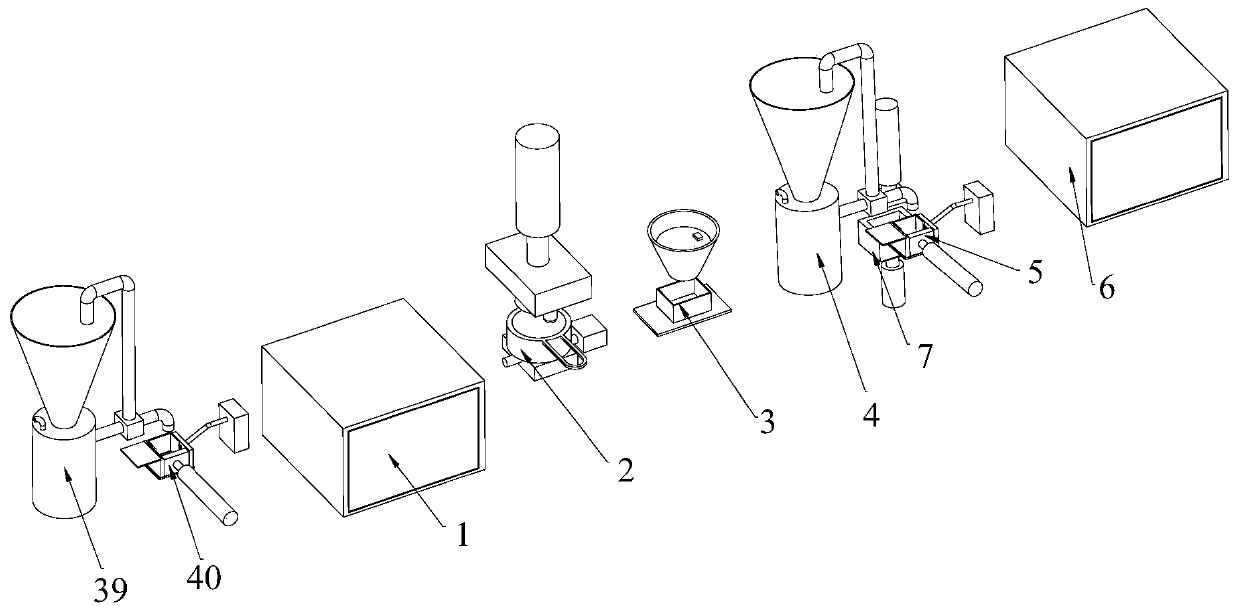

[0107] Such as figure 1 As shown, this embodiment discloses a curing device for implementing the method of the present application, and the curing device includes:

[0108] The first colloid mill 39 is used for grinding B2O3, Bi2O3, ZnO and SiO2;

[0109] The first drying device 40 is used to receive the raw material from the first colloid mill 39 and dry the raw material;

[0110] The first sintering device 1 is used to sinter the raw materials dried by the first drying device 40 to obtain glass ceramics;

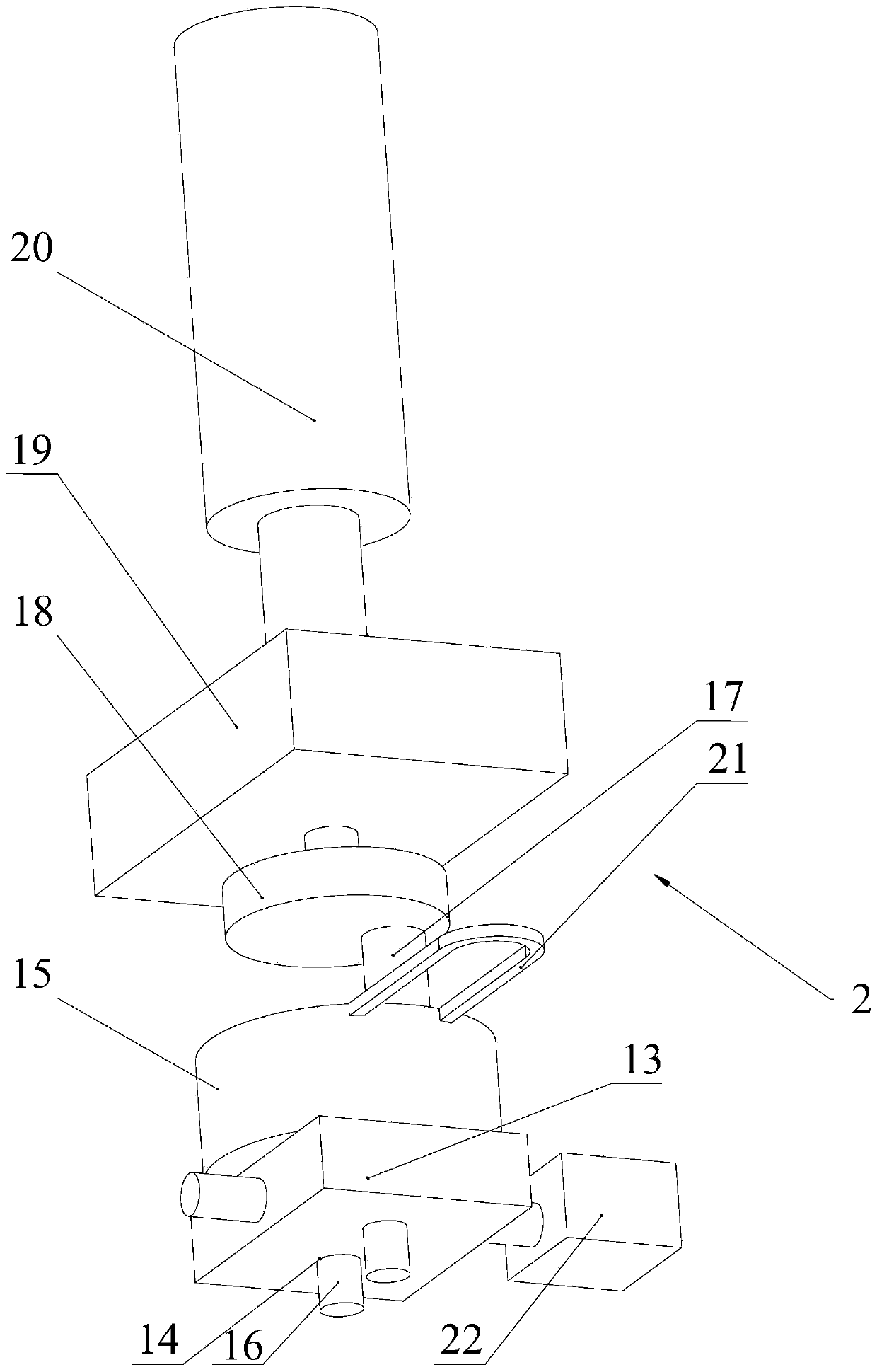

[0111] Glass-ceramic grinding device 2, for grinding glass-ceramic into glass-ceramic powder;

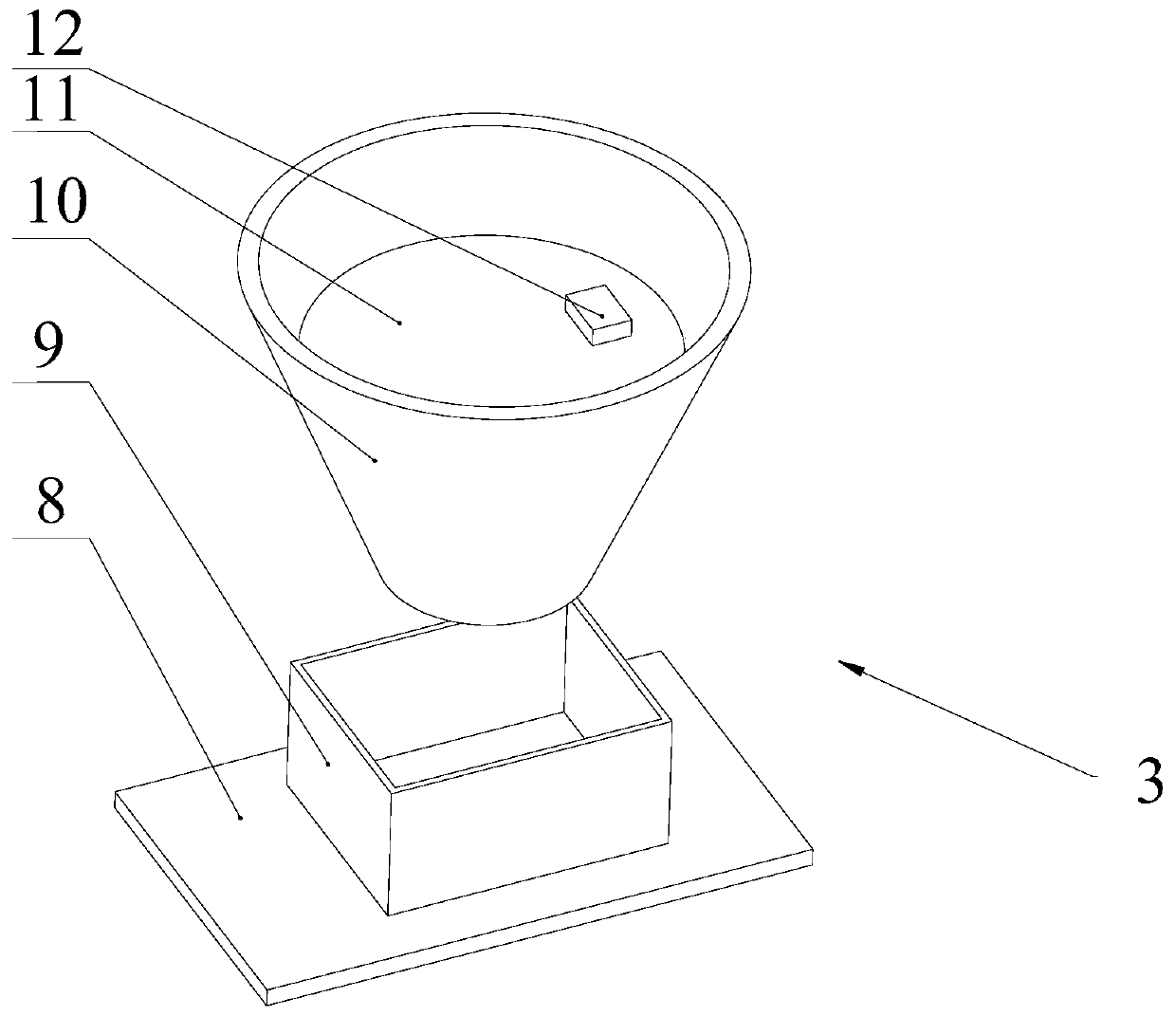

[0112] Silver-coated silica gel particle filter mechanism 3;

[0113] The second colloid mill 4 is used for mixing and grinding silver-coated silica gel particles and glass ceramic powder;

[0114] The second drying device 5 is used to receive the wet mixture from the second colloid mill 4, and dry the mixture to obtain a dry mixture;

[0115] The second sintering device 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com