Dextrin mortar composite material based on waste mineral powder and preparation method thereof

A composite material and dextrin technology, applied in the field of building materials, can solve problems such as waste of resources, and achieve the effects of saving production costs, good strength and waterproof performance, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

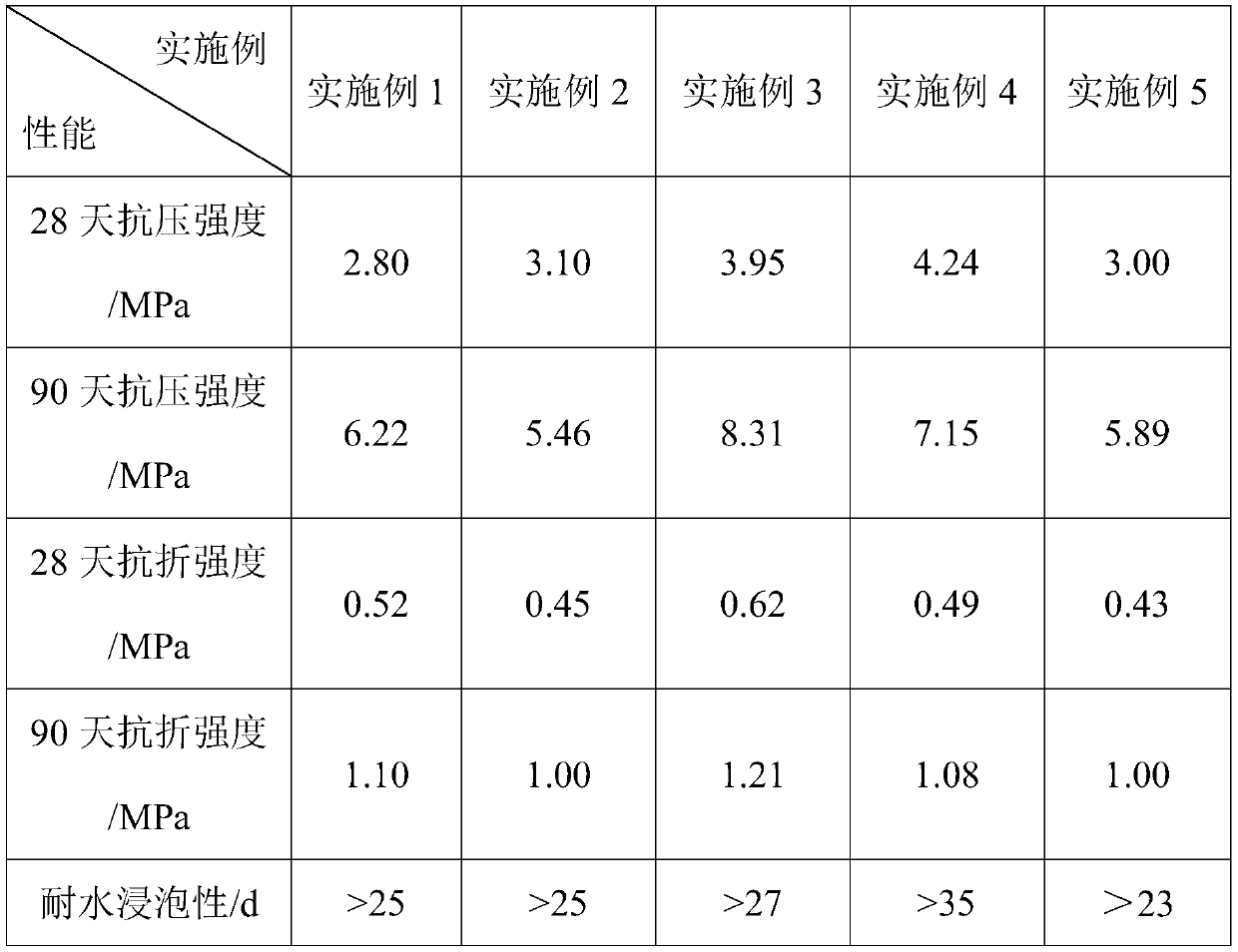

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing a dextrin mortar composite material based on waste ore powder, which is specifically implemented according to the following steps:

[0041] Step 1, take the following raw materials respectively by mass fraction:

[0042] Lime 20.1%, dextrin slurry 10.7%, mineral powder 12.6%, activator 1.2%, water 8.2%, sand 47.2%;

[0043] Among them, the activator is composed of sodium hydroxide and sodium silicate with a mass ratio of 1:2, the quality of the activator is 10% of the mass of mineral powder, and the mineral powder is 62.5% of the mass of lime; the dextrin slurry is composed of dextrin and water Composition with a mass ratio of 1:5.3;

[0044] Step 2. Preparation of gelling material A: Pour the activator and mineral powder into container A, add water and stir evenly, and leave for 1 minute to obtain gelling material A;

[0045] Step 3. Preparation of gelling material B: Pour the dextrin slurry and lime into container B, s...

Embodiment 2

[0048] This embodiment provides a kind of preparation method of the dextrin mortar composite material based on waste mineral powder, and this method is the same as embodiment 1, and difference is:

[0049] The raw materials weighed are lime 20%, dextrin slurry 4.2%, mineral powder 13.4%, activator 1.0%, water 7.0%, sand 54.4%;

[0050] Among them, the quality of the activator is 8% of the mass of the mineral powder; the mineral powder is 68.9% of the mass of the lime; the dextrin slurry is composed of dextrin and water with a mass ratio of 1:11.5;

[0051] The gelling material A was prepared in step 2, and stood for 2.5 minutes; the gelling material B was prepared in step 3, and stood for 3.5 minutes.

Embodiment 3

[0053] This embodiment provides a kind of preparation method of the dextrin mortar composite material based on waste mineral powder, and this method is the same as embodiment 1, and difference is:

[0054] The raw materials weighed are lime 31.6%, dextrin slurry 4.2%, mineral powder 10.5%, activator 1.1%, water 10.5%, sand 42.1%;

[0055] Among them, mineral powder is 33.3% of lime mass; dextrin slurry is composed of dextrin and water with a mass ratio of 1:5.3;

[0056] The gelling material A is prepared in step 2 and left for 2 minutes; the gelling material B is prepared in step 3 and left for 2 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com