A low-dielectric-constant poly(arylene ether nitrile) foam material having a double-peak foam structure, and a preparing method and use thereof

A technology of polyarylether nitrile and foam materials, which is applied in the field of special engineering plastics, can solve the problems of restricting the development of special engineering plastic foams, achieve good mechanical properties, passivate crack diffusion, and broaden the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

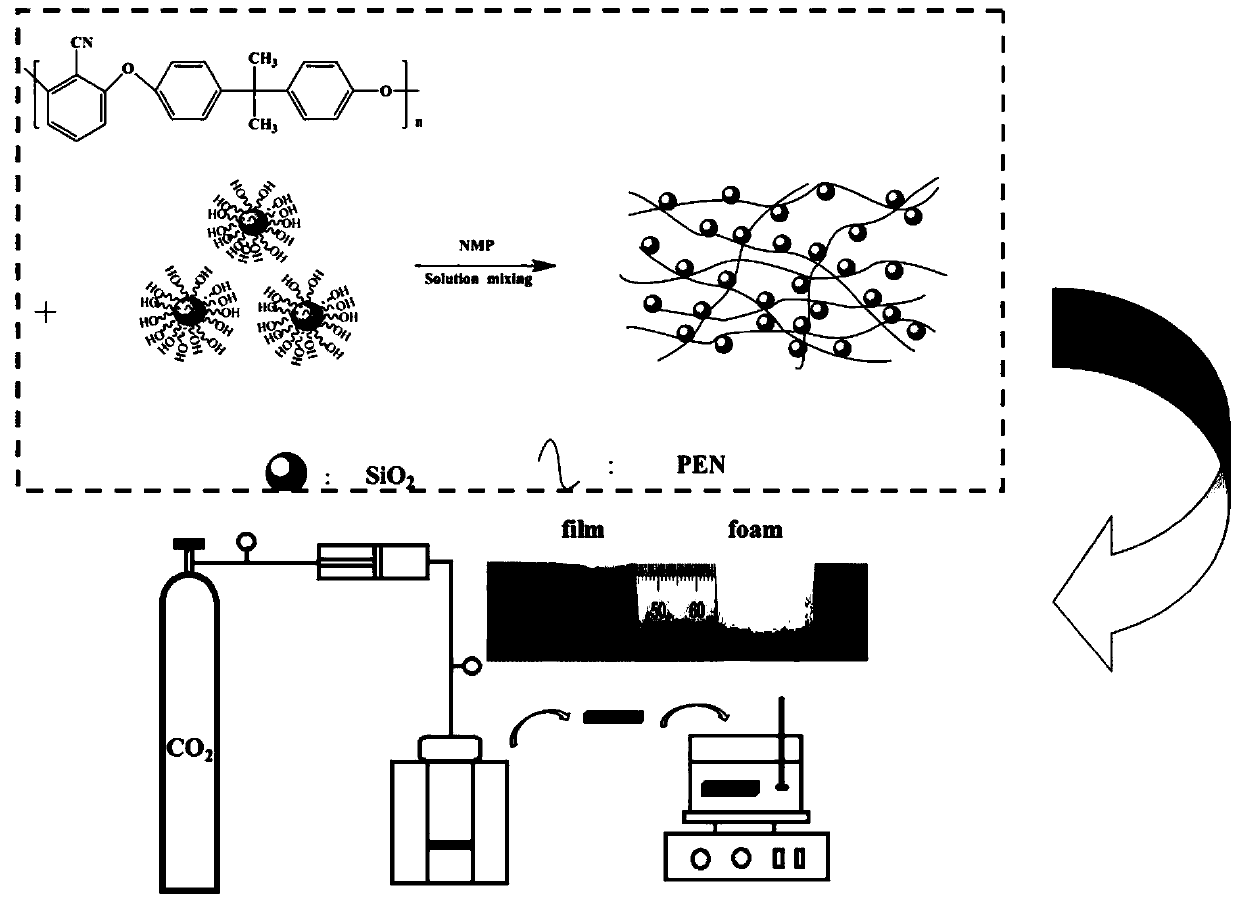

[0030] In any embodiment, the preparation method of the low-dielectric polyarylether nitrile foam material with bimodal cell structure of the present invention, the schematic diagram is as follows figure 1 As shown, it specifically includes the following steps:

[0031] 1) Preparation of samples to be foamed

[0032] Using N-methylpyrrolidone as solvent, a certain amount of nano-SiO 2 Add to the solvent and ultrasonically disperse for 30 minutes; in addition, use N-methylpyrrolidone as the solvent, add a certain amount of PEN powder into the solvent and stir at 200°C for 30 minutes to fully dissolve the PEN; then mix the above two solutions, stir and sonicate 30min; then pour the solution on the surface of a clean glass plate and cast it into a film; put the glass plate in an oven and dry it at 180°C for 12 hours to remove the solvent, and after the glass plate is naturally cooled to room temperature, immerse it in a water tank, and the film will fall off automatically ; Aft...

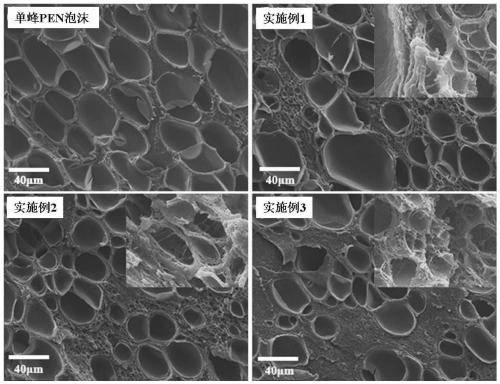

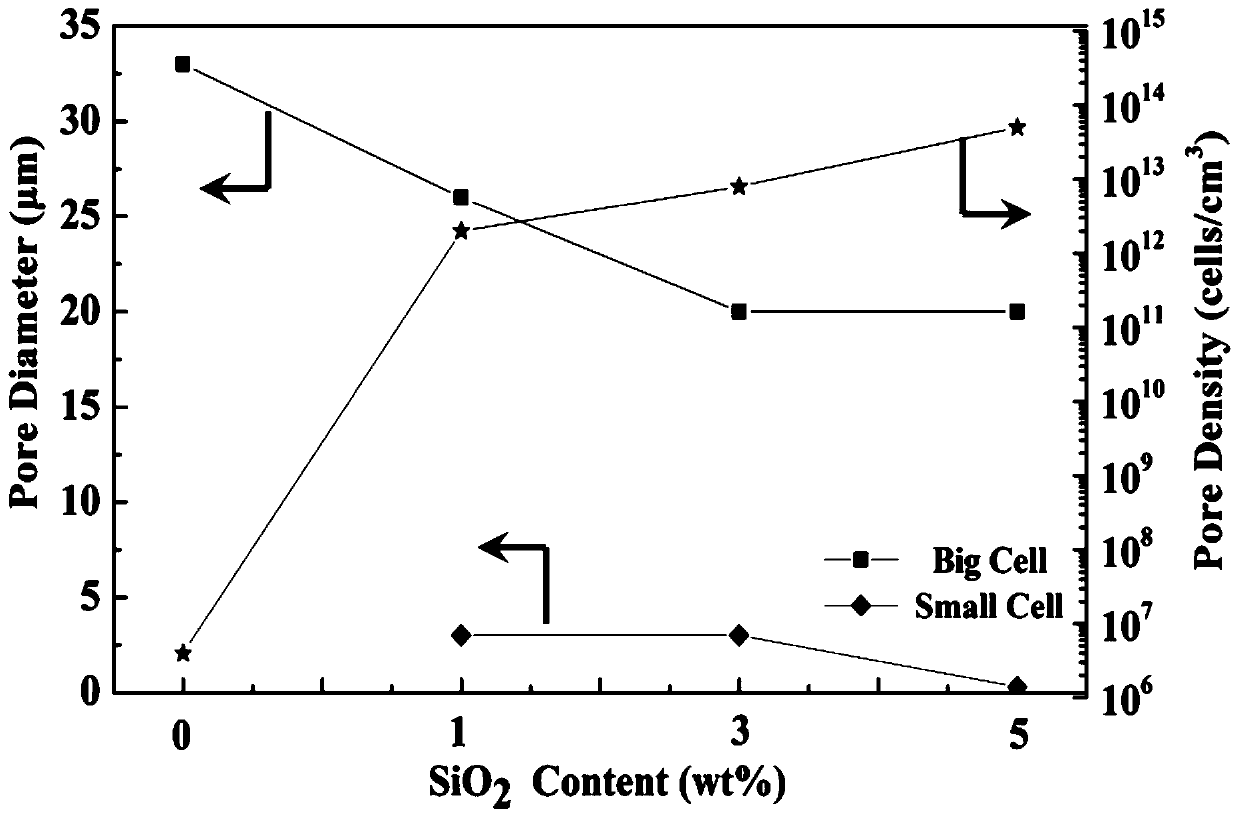

Embodiment 1

[0037] PEN resin and nano SiO 2 The matching ratio is as follows:

[0038] Raw material name

Embodiment 2

[0040] PEN resin and nano-SiO 2 The matching ratio is as follows:

[0041] Raw material name

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com