High-precision laser sensor with distance measuring function and laser control system

A laser sensor, high-precision technology, applied in the field of laser sensors, can solve the problems that the operator cannot judge the working range, cannot detect the receiving distance in real time, and cannot guarantee the leveling accuracy, etc., and achieves good spectral response characteristics, small detection errors, and guaranteed The effect of leveling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

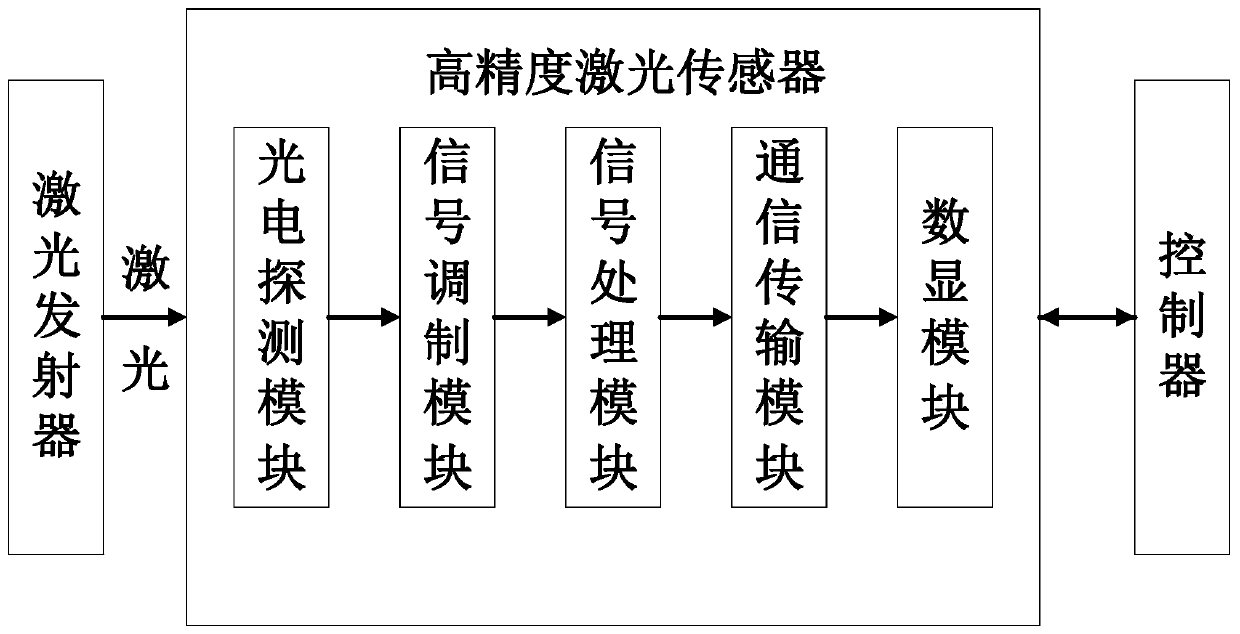

[0038] Such as figure 1 As shown, a high-precision laser sensor with ranging function includes: a photoelectric detection module, a signal modulation module, a signal processing module, a communication transmission module and a digital display module.

[0039] The photoelectric detection module is used to detect laser signals, and perform photoelectric conversion to output electrical signals. The signal modulation module modulates the electrical signal into a TTL level signal. The signal processing module converts the TTL level signal into a digital signal through a microprocessor and performs algorithm processing. The communication transmission module communicates with the controller through the bus. The digital display module feeds back the communication status, elevation position information and distance information from the laser transmitter in real time.

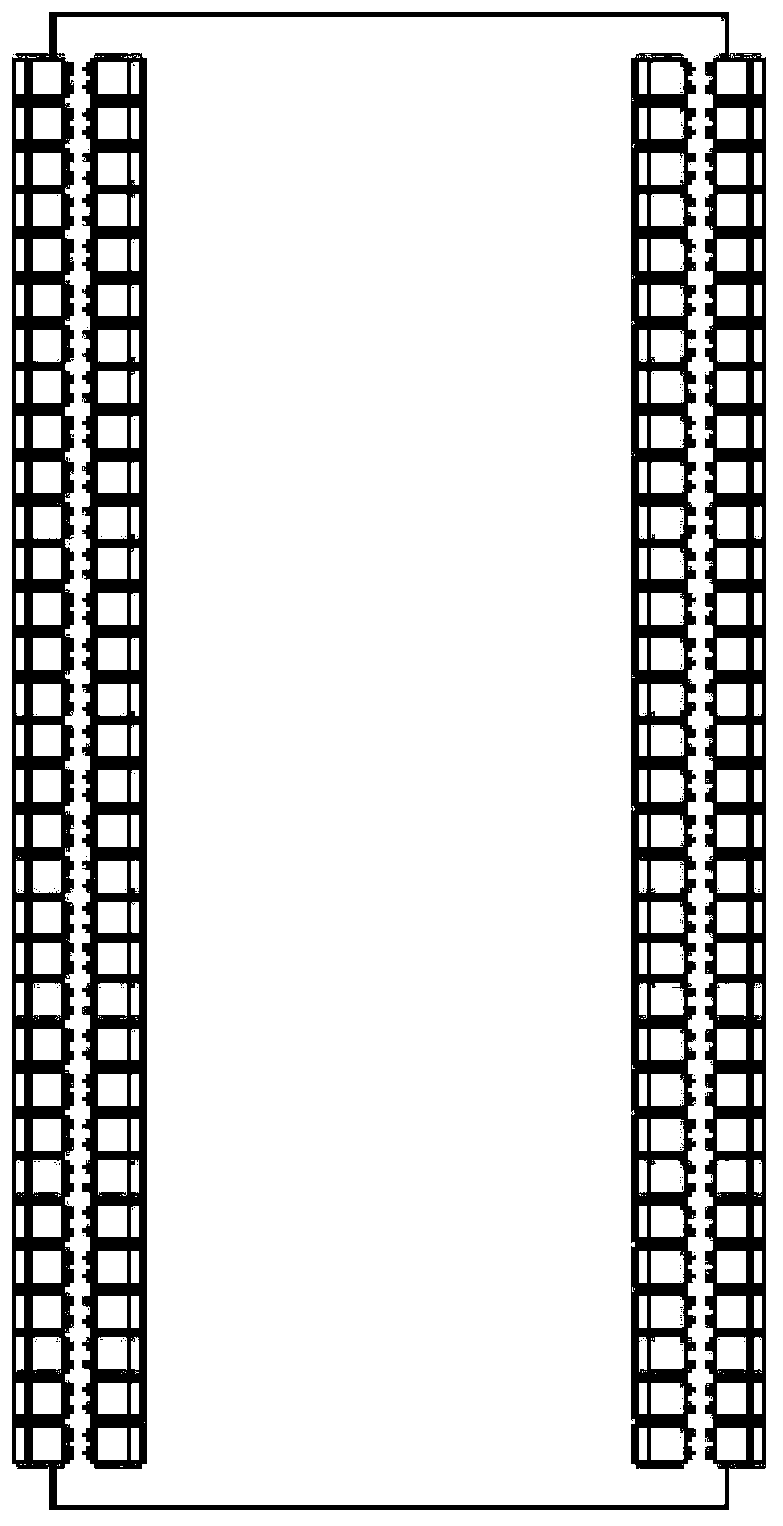

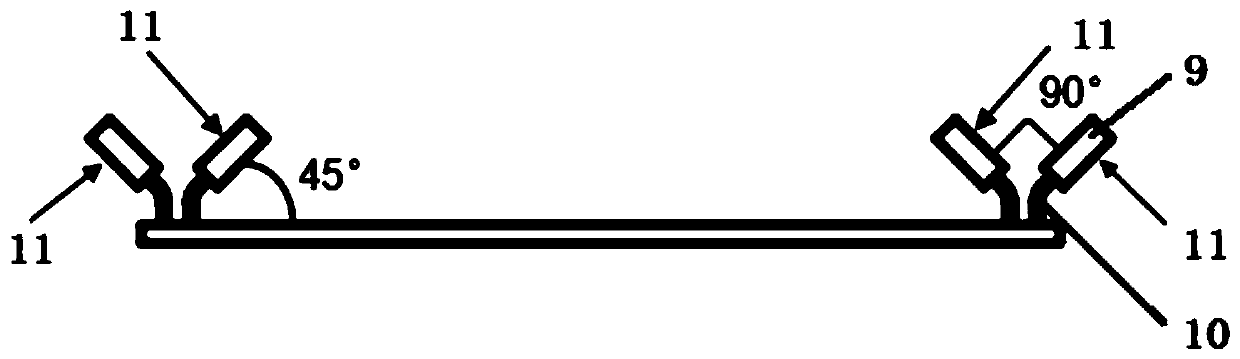

[0040] Such as figure 2 with image 3 As shown, the photoelectric detection module uses photodiodes to form a p...

Embodiment 2

[0044] In practical applications, the laser sensor provided in Example 1 is used together with the control system of the concrete leveling machine to carry out leveling operations on the building ground. The leveling accuracy is required to reach ±3mm. It can accurately judge the distance between the laser sensor and the laser emitter, so as to ensure that the concrete leveling machine always performs leveling operations within a high-precision range of tens of meters.

Embodiment 3

[0046] In practical applications, the laser sensor provided in Example 1 is used together with the paddy field or dry land laser grader control system to carry out farmland leveling operations. The leveling accuracy is required to reach ±20mm. During the process, the distance between the laser sensor and the laser emitter can be accurately judged, so as to ensure that the grader always performs leveling operations within the effective range of several hundred meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com