Low-carbon environment-friendly flyknit vamp, preparation method thereof and shoe produced by using same

A low-carbon environmental protection, flying weaving technology, applied in the field of flying weaving shoes, can solve the problems of low-carbon environmental protection, etc., and achieve the effect of reducing energy consumption, reducing pollution, heating up and keeping warm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

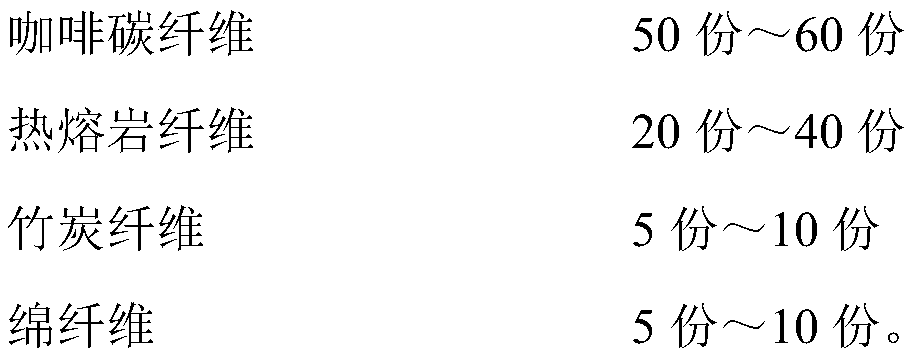

[0032] A low-carbon and environmentally friendly fly-woven shoe upper is made of the following components in parts by weight:

[0033]

[0034] Among them, coffee carbon fiber is made of coffee grounds as raw material, after high-temperature calcination treatment, so that the crystal phase and pores of coffee grounds are in the best state, and then ground into nano-scale powder, and then made into coffee carbon masterbatch, and then dried, spun Coffee carbon fiber made by silk and drawing.

[0035] Among them, hot lava fiber is a new type of textile fiber material processed by mixing volcanic lava "obsidian spar" nanocomposite materials and fiber raw materials.

[0036] Among them, the coffee carbon fiber and the hot lava fiber are both produced and provided by Foshan Nanhai Xiqiao Zhihong Textile Co., Ltd.

[0037] The above-mentioned preparation method of a low-carbon and environment-friendly flying woven shoe upper comprises the following steps:

[0038] Step 1, dope c...

Embodiment 2

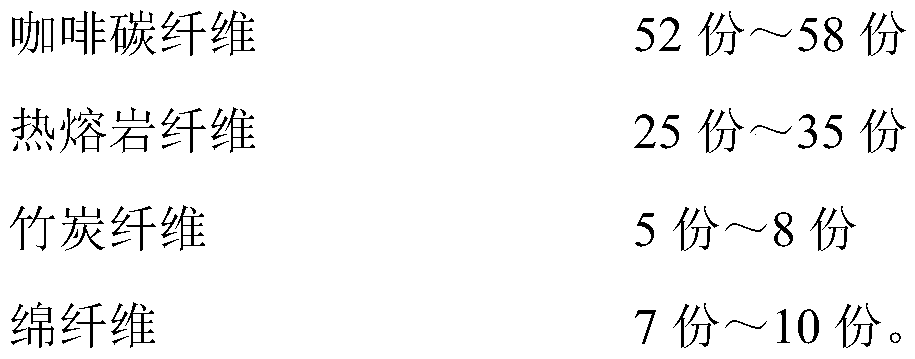

[0043] A low-carbon and environmentally friendly fly-woven shoe upper is made of the following components in parts by weight:

[0044]

[0045] Among them, coffee carbon fiber is made of coffee grounds as raw material, after high-temperature calcination treatment, so that the crystal phase and pores of coffee grounds are in the best state, and then ground into nano-scale powder, and then made into coffee carbon masterbatch, and then dried, spun Coffee carbon fiber made by silk and drawing.

[0046] Among them, hot lava fiber is a new type of textile fiber material processed by mixing volcanic lava "obsidian spar" nanocomposite materials and fiber raw materials.

[0047] Among them, the coffee carbon fiber and the hot lava fiber are both produced and provided by Foshan Nanhai Xiqiao Zhihong Textile Co., Ltd.

[0048] The above-mentioned preparation method of a low-carbon and environment-friendly flying woven shoe upper comprises the following steps:

[0049] Step 1, dope c...

Embodiment 3

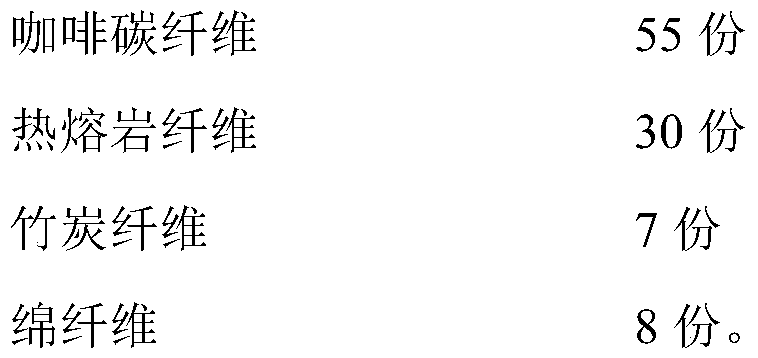

[0054] A low-carbon and environmentally friendly fly-woven shoe upper is made of the following components in parts by weight:

[0055]

[0056] Among them, coffee carbon fiber is made of coffee grounds as raw material, after high-temperature calcination treatment, so that the crystal phase and pores of coffee grounds are in the best state, and then ground into nano-scale powder, and then made into coffee carbon masterbatch, and then dried, spun Coffee carbon fiber made by silk and drawing.

[0057] Among them, hot lava fiber is a new type of textile fiber material processed by mixing volcanic lava "obsidian spar" nanocomposite materials and fiber raw materials.

[0058] Among them, the coffee carbon fiber and the hot lava fiber are both produced and provided by Foshan Nanhai Xiqiao Zhihong Textile Co., Ltd.

[0059] The above-mentioned preparation method of a low-carbon and environment-friendly flying woven shoe upper comprises the following steps:

[0060] Step 1, dope c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com