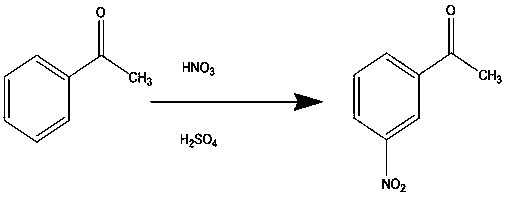

Treatment method of waste acid generated by synthesis of m-nitroacetophenone

A technology for the treatment of nitroacetophenone and waste acid, which is applied in the chemical industry, can solve the problems of producing a large amount, the production equipment is corrosive, and cannot meet the requirements of sustainable development, and achieves the effect of reducing pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

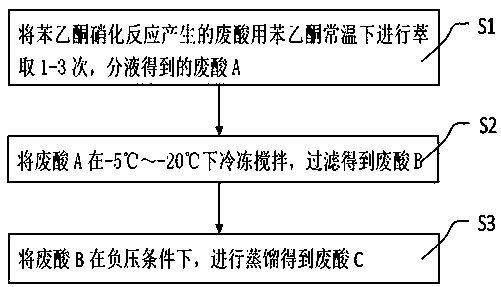

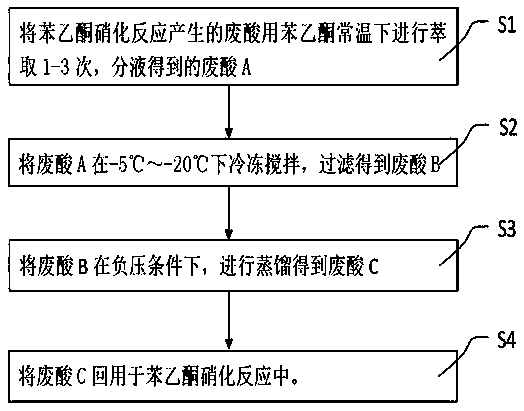

Method used

Image

Examples

Embodiment 1

[0033] Add 69.6g of concentrated sulfuric acid into a 500ml beaker equipped with mechanical stirring and a thermometer, specifically mix 77.06g of concentrated sulfuric acid with a concentration of 92.04% and 19.54g of concentrated sulfuric acid with a concentration of 98%, and then pipette 15ml as a compounding acid 27g of sulfuric acid; start stirring, and slowly add 15g of acetophenone dropwise under the condition of keeping the temperature not exceeding -7°C, so that the reaction temperature is controlled below -10°C and slowly add a mixed acid nitrating reagent, specifically 10ml of fuming nitric acid Pipette and mix with 15ml of the aforementioned mixture of concentrated sulfuric acid, control the speed of dripping, and keep warm for 5 minutes after the completion of the dropwise addition. After the reaction is completed, pour the reaction solution into a beaker containing 100g of ice-water mixture, keep stirring rapidly, and wait until the ice-water mixture is filled. Co...

Embodiment 2

[0036] Add 69.6g of concentrated sulfuric acid into a 500ml beaker equipped with mechanical stirring and a thermometer, specifically mix 78.64g of concentrated sulfuric acid with a concentration of 92.55% and 17.96g of concentrated sulfuric acid with a concentration of 98%, and then pipette 15ml as a compounding acid 27g of sulfuric acid; start stirring, and slowly add 15g of acetophenone dropwise under the condition of keeping the temperature not exceeding -7°C, so that the reaction temperature is controlled below -10°C and slowly add a mixed acid nitrating reagent, specifically 10ml of fuming nitric acid Pipette and mix with 15ml of the aforementioned mixture of concentrated sulfuric acid, control the speed of dripping, and keep warm for 5 minutes after the completion of the dropwise addition. After the reaction is completed, pour the reaction solution into a beaker containing 100g of ice-water mixture, keep stirring rapidly, and wait until the ice-water mixture is filled. Co...

Embodiment 3

[0039] Add 69.6g of concentrated sulfuric acid in a 500ml beaker equipped with mechanical stirring and a thermometer, specifically after mixing 78.46g of 92.22% concentration with 18.14g of concentration 98% concentration of sulfuric acid, then pipette 15ml of sulfuric acid 27g as a compounding acid; Start stirring, and slowly add 15g of acetophenone dropwise under the condition that the temperature does not exceed -7°C, so that the reaction temperature is controlled below -10°C and slowly add a mixed acid nitration reagent, specifically 10ml of fuming nitric acid and 15ml of the above-mentioned pipette Take the mixed concentrated sulfuric acid mixture, control the dropping speed, keep warm for 5 minutes after the dropping is completed, after the reaction is completed, pour the reaction solution into a beaker containing 100g of ice-water mixture, keep stirring rapidly, until the ice is completely melted and vacuum Suction filtration, press dry the solid as much as possible, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com