Anti-fatigue multilayer steel smooth sucker rod and processing process thereof

A multi-layer structure, pumping polished rod technology, applied in drill pipe, drilling equipment, earth-moving drilling, etc., can solve the problems of difficult control of production links, increase processing cost and difficulty, limit popularization and application, etc. The effect of bending performance and fatigue resistance, good comprehensive mechanical properties, excellent toughness and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

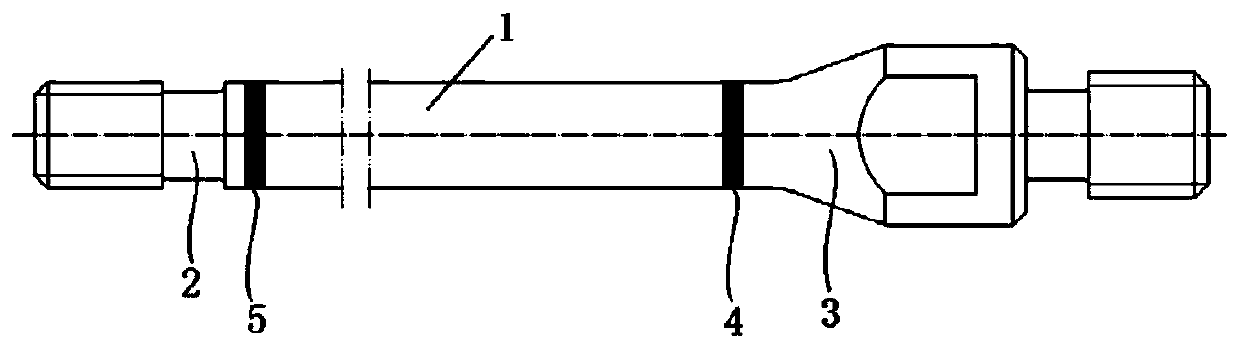

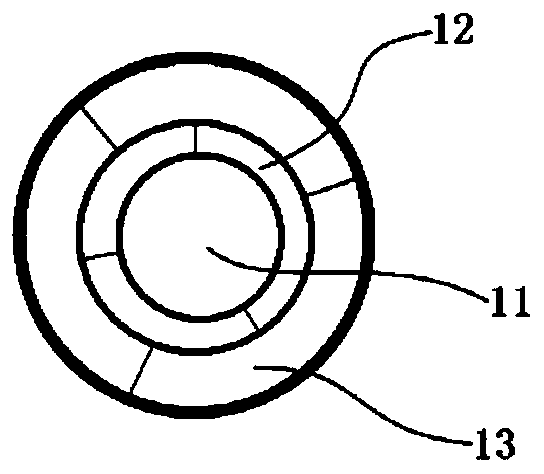

[0027] see figure 1 and figure 2, according to the present invention provides a kind of anti-fatigue multi-layer structure steel oil pumping polished rod, its technical scheme is as follows: It includes upsetting end 3, rod body 1 and closed end 2, and the rod body 1 is placed on the upsetting end Between the head 3 and the closed end 2, the rod body 1 and the cross section of the upset end 3 are connected by a weld 4 welded by friction welding, and the rod body 1 and the closed end The cross-sections of the ends 2 are connected by a weld 5 welded by a friction welding process. The rod body 1 includes a solid steel core rod 11 and a tubular outer layer, and the tubular outer layer includes a first outer layer 12 and The second outer layer 13, the tubular outer layer is composed of arc-shaped steel bars, the tubular outer layer is composed of arc-shaped steel bars, the length of the arc-shaped steel bars is consistent with the solid steel core rod , the first outer layer 12 ...

Embodiment 2

[0035] According to a kind of anti-fatigue multi-layer structure steel oil sucking polished rod provided by the present invention, its technical solution is basically the same as that of Embodiment 1, the difference is as follows: the tubular outer layer includes a first outer layer, a second outer layer and a second outer layer Three outer layers, the tubular outer layer is composed of arc-shaped steel bars, the first outer layer, the second outer layer and the third outer layer each include five arc-shaped steel bars, and the solid steel core rod It is a medium-low carbon chromium-molybdenum alloy steel, with a yield strength of 670 MPa at 0.2% residual deformation, a tensile strength of 840 MPa, an elongation of 11%, and a reduction of area of 35%; the arc-shaped steel bar of the first outer layer It is tough steel with 0.2% residual deformation yield strength of 850 MPa, tensile strength of 960 MPa, elongation of 13%, reduction of area of 52%, and the total content of a...

Embodiment 3

[0037] According to a kind of anti-fatigue multi-layer structure steel oil pumping polished rod provided by the present invention, its technical solution is basically the same as that of Embodiment 1, the difference is as follows: the tubular outer layer includes a first outer layer, a second outer layer, a second outer layer, and a second outer layer. Three outer layers, the fourth outer layer and the fifth outer layer, the tubular outer layer is composed of arc-shaped steel bars, the first outer layer, the second outer layer, the third outer layer, the fourth outer layer and the first outer layer Each of the five outer layers includes seven arc-shaped steel bars. The solid steel core rod is a medium-low carbon chromium-molybdenum alloy steel with a yield strength of 650 MPa at 0.2% of residual deformation, a tensile strength of 830 MPa, and an elongation of 10%. The reduction of area is 32%; the arc-shaped steel bar of the first outer layer is strong and tough steel, the yiel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com