Diversion tunnel extremely-weak surrounding rock section construction method

A technology for water diversion tunnels with weak surrounding rocks, applied in the field of tunnels, can solve problems such as difficulty in forming rapid closure, difficulty in controlling the setting time, and large diffusion range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Specific engineering application examples of pea gravel backfill grouting provided by the embodiments of the present invention;

[0067] 1) Project overview

[0068] The excavation diameter of the TBM tunnel in this project is 5.48m, the tunnel forming diameter is 4.6m, and the thickness of the segment is 30cm. The gap between the excavated tunnel section and the segment is backfilled with mortar within 90° of the bottom arch, and the rest of the gap is backfilled with pea pebbles grouting.

[0069] During the backfill grouting process, due to the large gap between the segment and the surrounding rock, it is difficult to start the pressure during the grouting process, the backfill grouting cannot be closed normally, and the grouting process cannot be implemented normally, resulting in the grouting being not dense. According to engineering practice, it is planned that every 50m ~ 100m form a closed loop.

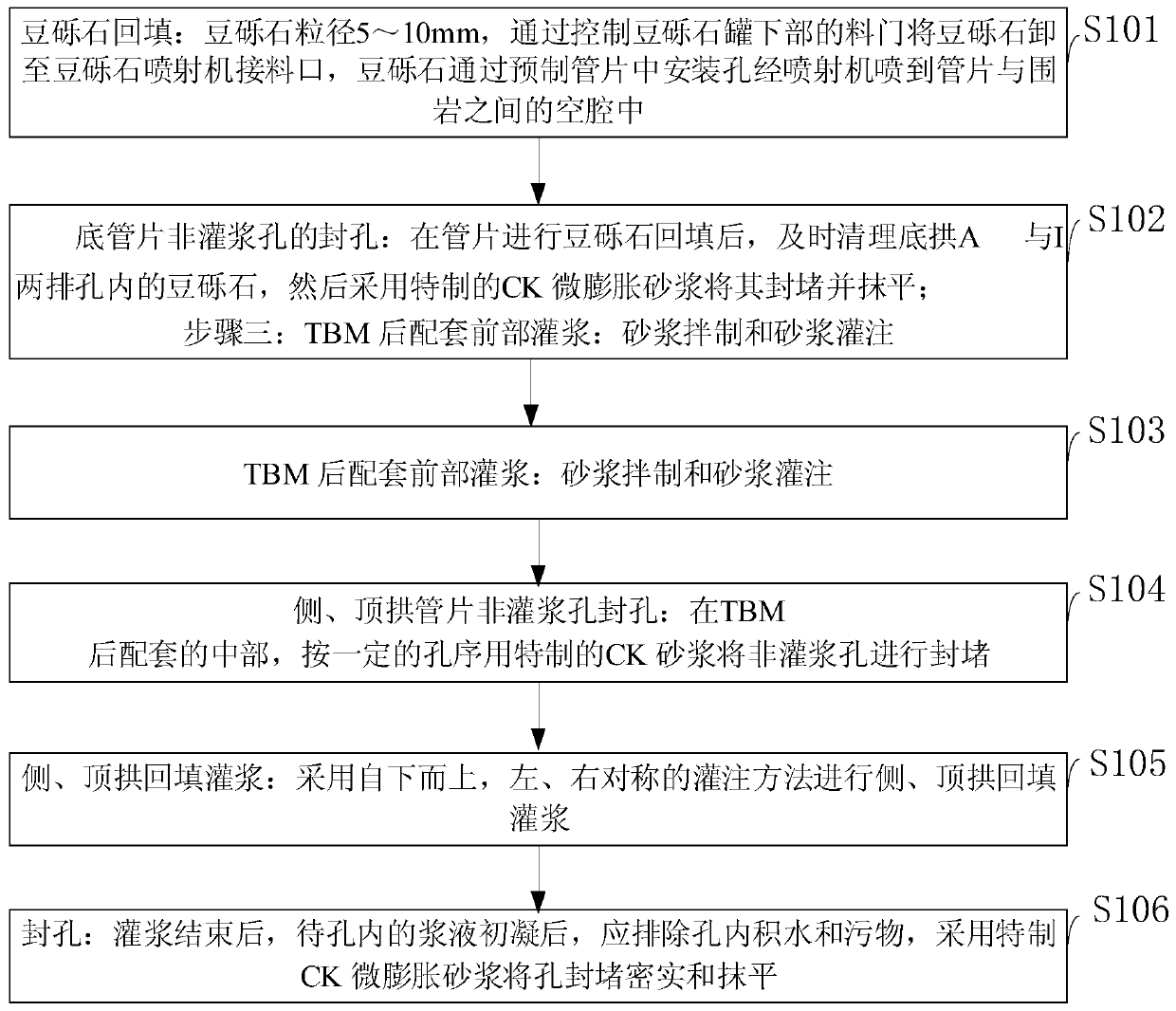

[0070] Closed loop implementation steps:

[0071] (1) A specia...

Embodiment 2

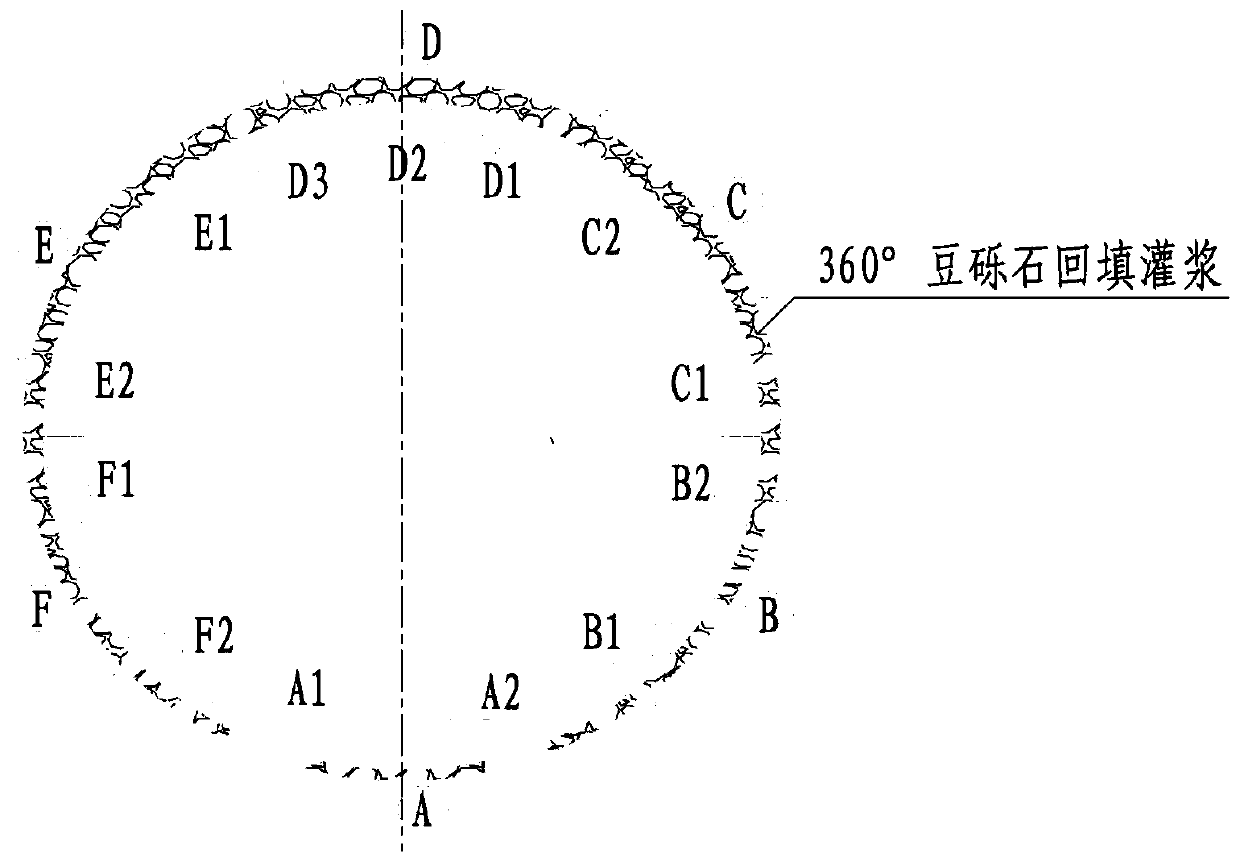

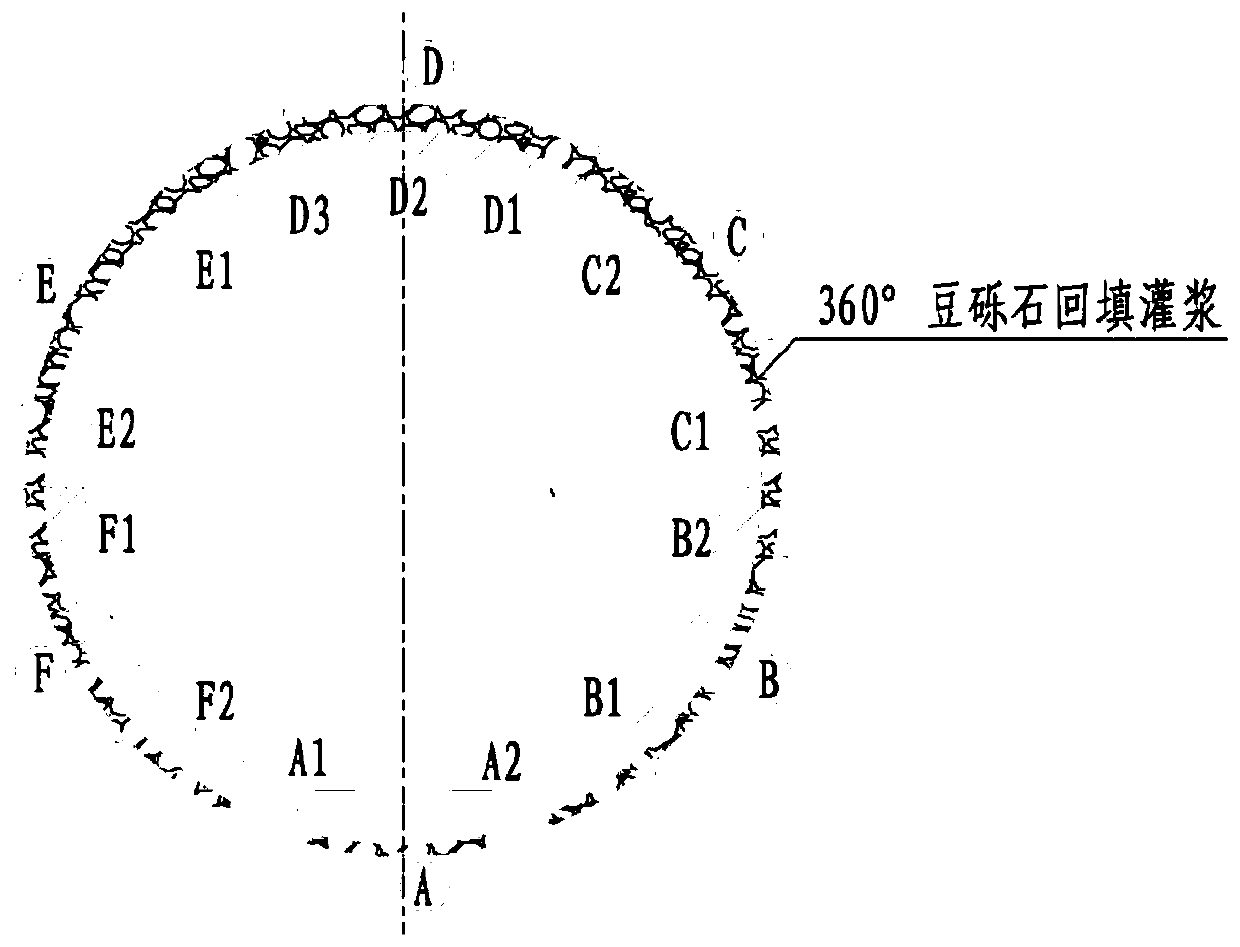

[0130] TBM construction includes 5# construction branch tunnel K0+558.3~K+3+535.04 and water conveyance main tunnel T5+580~T16+110 TBM construction tunnel section, using a double shield TBM for construction, 5# construction branch tunnel (TBM access tunnel) length 3535.04m, TBM construction section longitudinal slope -2.365%, excavation length 2976.74m, main tunnel stake number T5+850~T16+110, length 10260m, longitudinal slope 0.1%, of which stake number T5+850~ T10+950 and T12+750~T15+100 are excavated by TBM with a total length of 7.45km. The excavation diameter of the TBM is 5.48m, and the section is circular. Prefabricated C50 and C60 concrete segment linings are used. The inner diameter of the segment lining is 4.6m, the thickness of the segment is 30cm, and the outer diameter of the segment is 5.2m. The 360° range of the void is filled with pea gravel and backfilled with grouting.

[0131] Such as figure 2 As shown, the schematic diagram of the grouting area behind th...

Embodiment 3

[0159] 1), TBM bean gravel backfill grouting construction process:

[0160] (1) Construction process

[0161] Bean gravel backfilling→pointing→closed ring→bottom arch filling quick-setting cement slurry→side arch non-grouting hole sealing→primary grouting→secondary grouting→sealing→checking

[0162] (2) Bean gravel dredging: When the segment is pushed out of the tail shield, the pea gravel on both sides of the segment should be backfilled first, and then the top bean gravel should be backfilled.

[0163] (3) Bottom grouting: to discharge the flowing water (construction water and external water) in the cavity of the partition bottom arch. Construction backfilling and grouting When the bottom arch segments are assembled, use bagged gypsum powder or bagged mortar mixed with dry material to seal. Then do the bottom grouting.

[0164] (iv) Closed ring grouting: set a closed ring every 30-50 meters for pressure grouting grout sealing.

[0165] (5) One-time grouting: After the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com