Multifunctional shield synchronous grouting model test apparatus

A model test device, synchronous grouting technology, applied in vertical shaft equipment, shaft lining, mining equipment, etc., can solve problems such as single

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

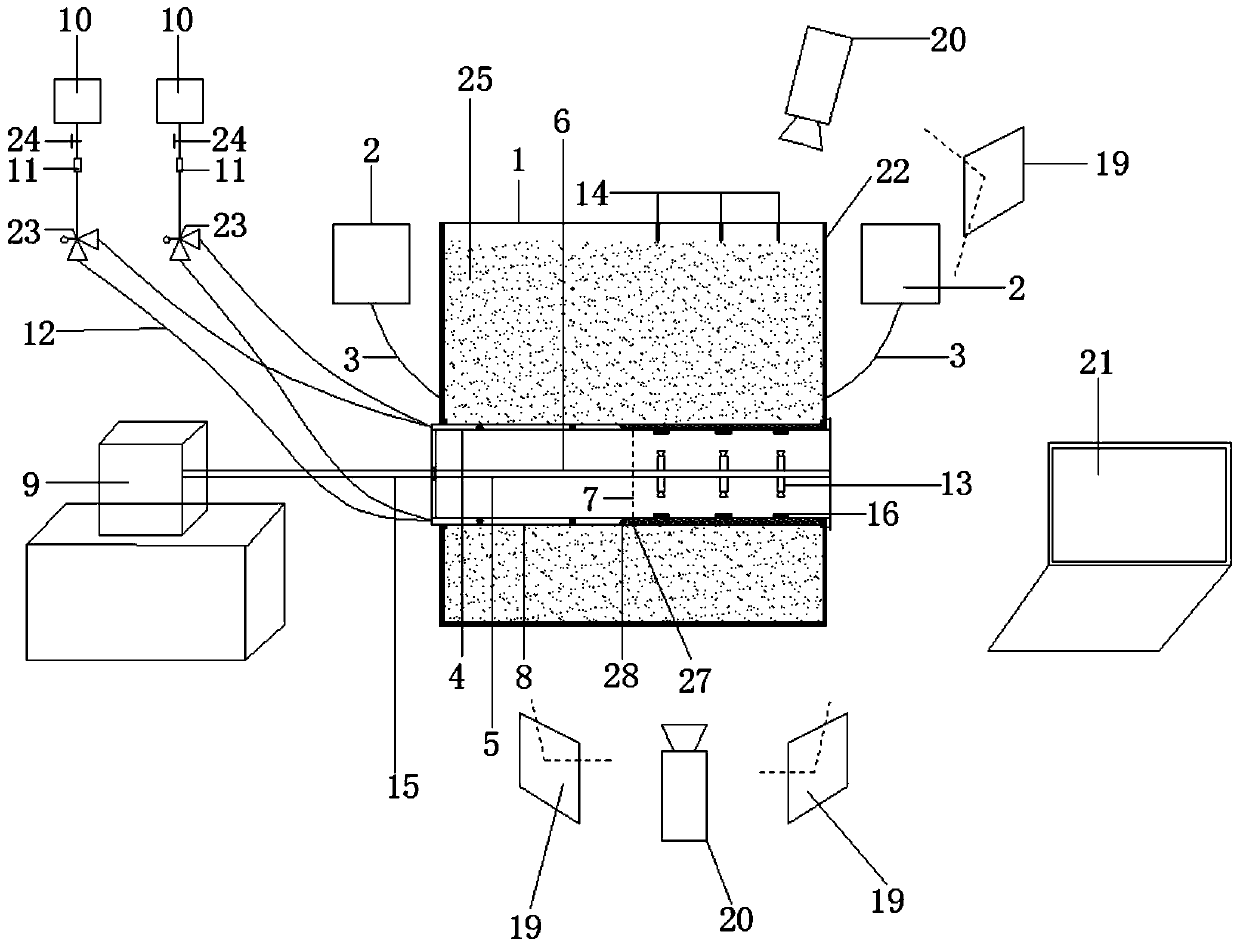

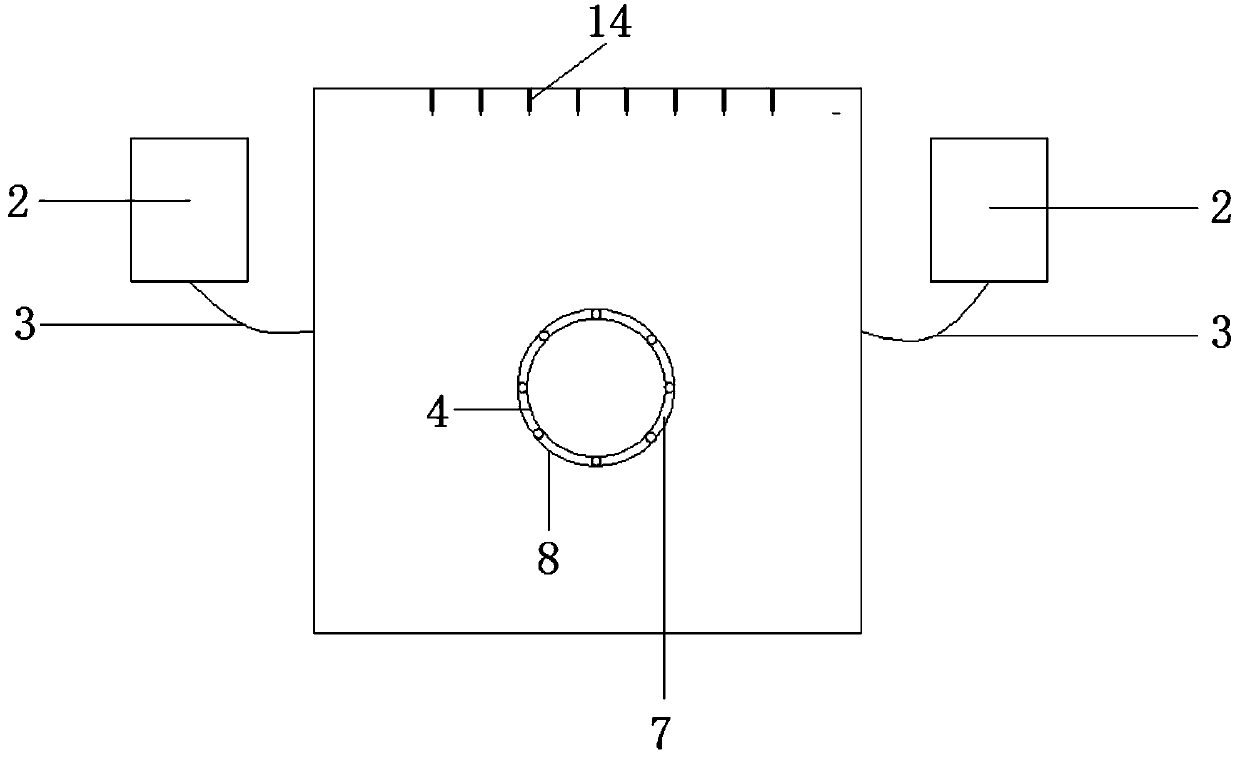

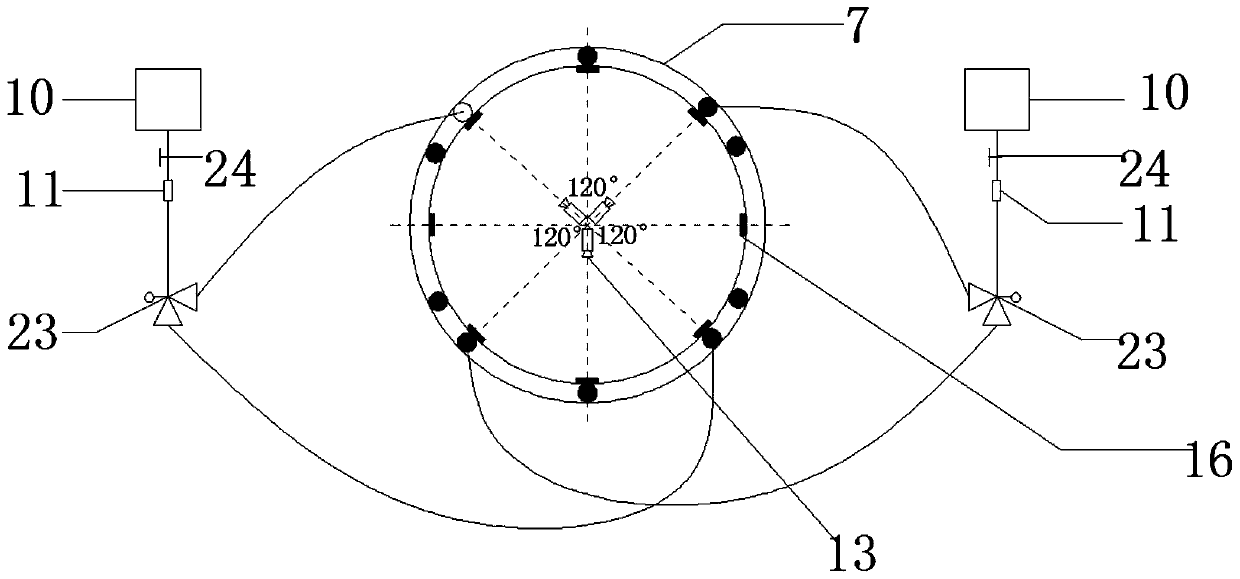

[0024] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0025] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

[0026] Transparent soil box 1; water tank 2; water guide pipe 3; simulated segment 4; fixed rod 5; push rod 6; grouting ring piece 7; simulated shield tail 8; propulsion hydraulic cylinder 9; 11; grouting pipeline 12 grouting pipeline; high-definition wide-angle camera 13; displacement sensor 14; moving rod 15; grouting pressure sensor 16; pore water pressure sensor 17; earth pressure sensor 18; laser 19; high-precision camera 20; Computer 21; organic transparent glass plate 22; three-way flow valve 23; control valve 24; transparent soil 25; ball 26; shield tail brush 27;

[0027] combine figure 1 , figure 2As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com