Buckling-resistant anti-peep film

An anti-peep film and bending-resistant technology, applied in optics, instruments, optical components, etc., can solve the problems of difficult to control the thickness of vinyl, uneven filling, slow speed, etc., and achieve easy peeling, good toughness, and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

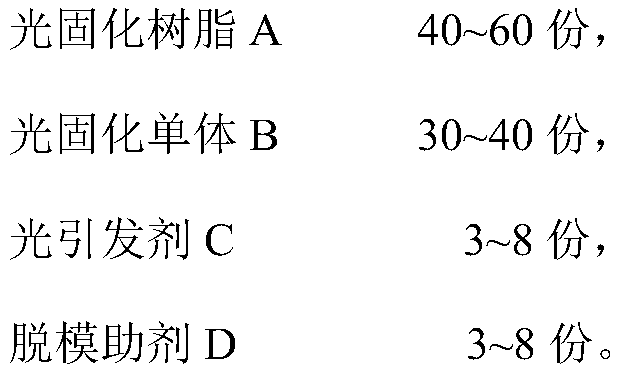

[0044] The parts by mass of each component of the glue in the transmission layer are as follows: 40 parts of DR-U029 (manufactured by Changxing) for oligomers, 4 parts of functionality, 40 parts of OPPEA (manufactured by KPX) for monomers, and 184 (double Key Chemical Manufacturing) 4 parts, TPO (Double Bond Chemical Manufacturing) 0.5 parts, release aid is ZG-400 (TEGO Company) 5 parts.

[0045] The parts by mass of each component of the absorbing layer glue are as follows: 30 parts of polyether polyurethane methacrylate BR-202 (DYMAX company) for oligomers, 30 parts of monomer BPA8EODA (DSM), and 30 parts of monomer OPPEA (manufactured by KPX) is 5 parts, the auxiliary agent is 1 part of RAD2200 (TEGO company), the initiator is selected as 1 part of 127 (manufactured by double bond chemical industry), 2 parts of TPO (manufactured by double bond chemical industry), 7 parts of color paste, Thiol accounts for 3 parts.

[0046] The substrate layer is a PET substrate produced by...

Embodiment 2

[0048] The parts by mass of each component of the glue in the transmission layer are as follows: 40 parts of DR-U029 (manufactured by Changxing) for oligomers, 4 parts of functionality, 40 parts of OPPEA (manufactured by KPX) for monomers, and 184 (double Key Chemical Manufacturing) 4 parts, TPO (Double Bond Chemical Manufacturing) 1.5 parts, release aid is ZG-400 (TEGO Company) 3 parts.

[0049] The parts by mass of each component of the glue for the absorption layer are: 30 parts of polyether polyurethane methacrylate BR-202 (DYMAX company) for oligomers, 30 parts of monomer BPA8EODA (DSM), and 30 parts of monomer OPPEA (manufactured by KPX) is 5 parts, the additive is 1 part of RAD2200 (TEGO company), the initiator is selected as 1 part of 127 (manufactured by double bond chemical industry), 2 parts of TPO (manufactured by double bond chemical industry), 784 (manufactured by double bond chemical industry) ) 0.2 parts. The color paste accounts for 7 parts, and the mercaptan...

Embodiment 3

[0052]The parts by mass of each component of the glue in the transmission layer are as follows: 15 parts of CN8010NS (manufactured by Sartomer) and 35 parts of 6158B-80 (manufactured by Changxing) are selected as the oligomer, and the average functionality of the mixture is 3.5; the monomer is selected from OPPEA (manufactured by KPX) 35 parts; the initiator is selected as 4 parts of 184 (manufactured by double bond chemical industry), 1.5 parts of TPO (manufactured by double bond chemical industry); the demoulding aid is 5 parts of ZG-400 (manufactured by TEGO company).

[0053] The parts by mass of each component of the glue in the absorbing layer are: 30 parts of polyester polyurethane methacrylate XR-741MS (DYMAX company) for oligomer, 30 parts of monomer BPA6EODA (DSM), and 30 parts of monomer OPPEA (KPX company) ratio is 5 parts, auxiliary agent RAD2200 (TEGO company) 1 part, initiator is selected as 127 (manufactured by double bond chemical industry) 1 part, TPO (manufac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com