Full-automatic tray type slide vibration cleaning mechanism

A cleaning mechanism and tray-type technology, applied to dryers, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of low cleaning efficiency, affecting detection results, poor cleaning effect, etc., and achieve good cleaning effect , improve cleaning efficiency, and meet the effect of rapid inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

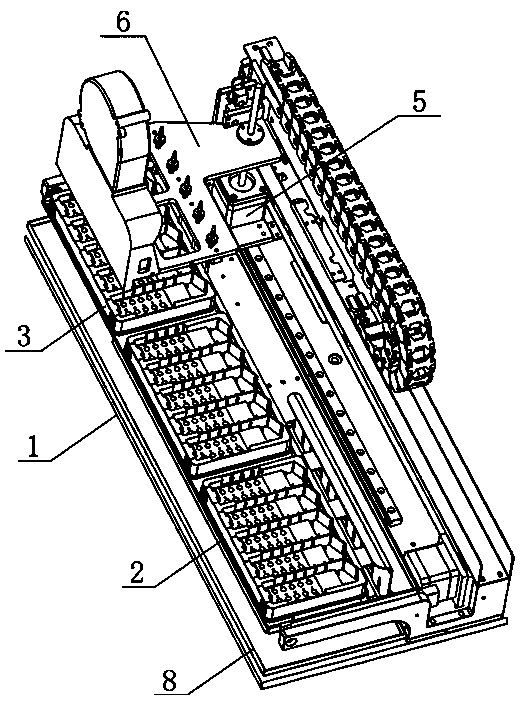

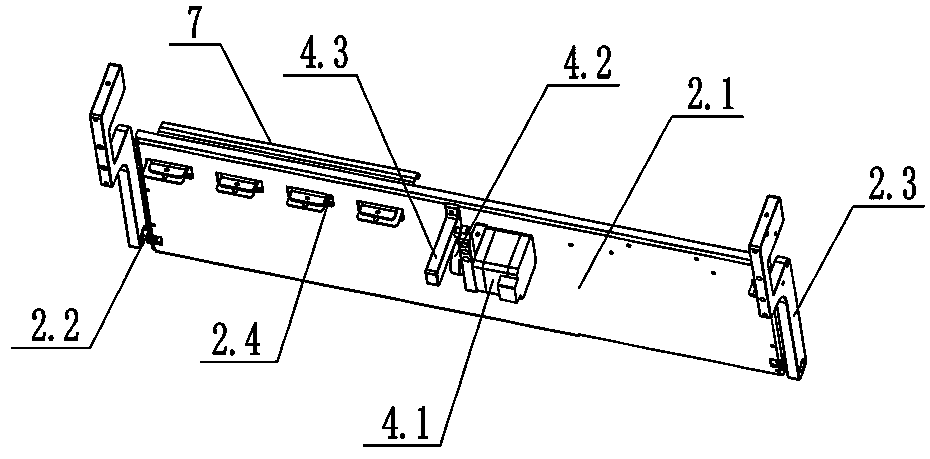

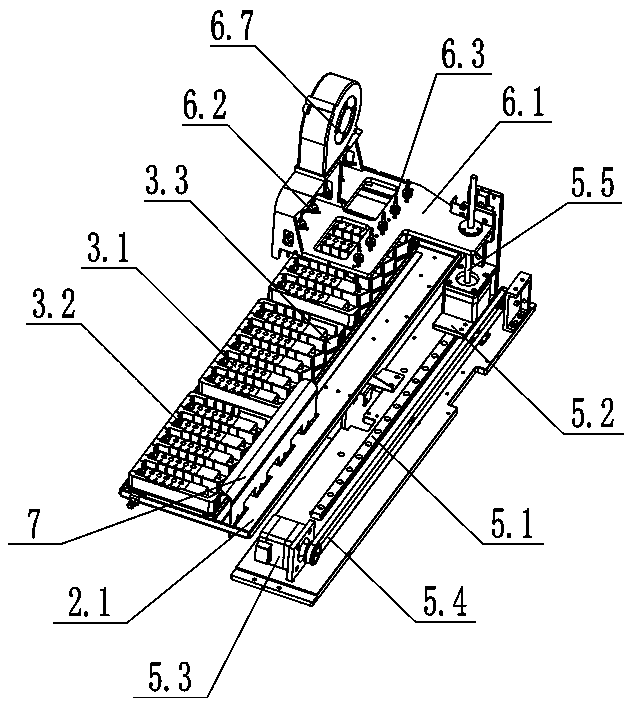

[0020] like figure 1 As shown, the full-automatic tray-type slide cleaning mechanism of the present invention includes a base 1 on which a shaking table 2 connected to the shaking mechanism is hinged, and the shaking table 2 includes a platform for placing a slide tray 3 Supporting plate 2.1, both sides of supporting plate 2.1 are connected with grooved support arm 2.3 through rotating shaft 2.2, and support arm 2.3 is fixed on the base 1. like figure 2 As shown, a rocking motor 4.1 is installed at the bottom of the supporting plate 2.1, and the rocking motor 4.1 is connected to the ejector rod 4.3 between the base 1 and the shaking table 2 through a cam 4.2. When the shaking motor 4.1 is started, the shaking table 2 will shake, causing the liquid in the slide tray 3 to shake, thereby improving the washing effect on the slide. The supporting plate 2.1 is provided with three stations successively along the length direction: cleaning area, soaking area, and air-drying area, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com