Feeding device for a die-cutting creasing machine

A technology of feeding device and creasing machine, which is applied in the direction of transportation and packaging, conveyor objects, machining/deformation, etc. It can solve the problems that affect the production progress, easy to get stuck at the die-cutting station, etc., and improve production efficiency , reduce the risk of abnormal shutdown, reduce the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

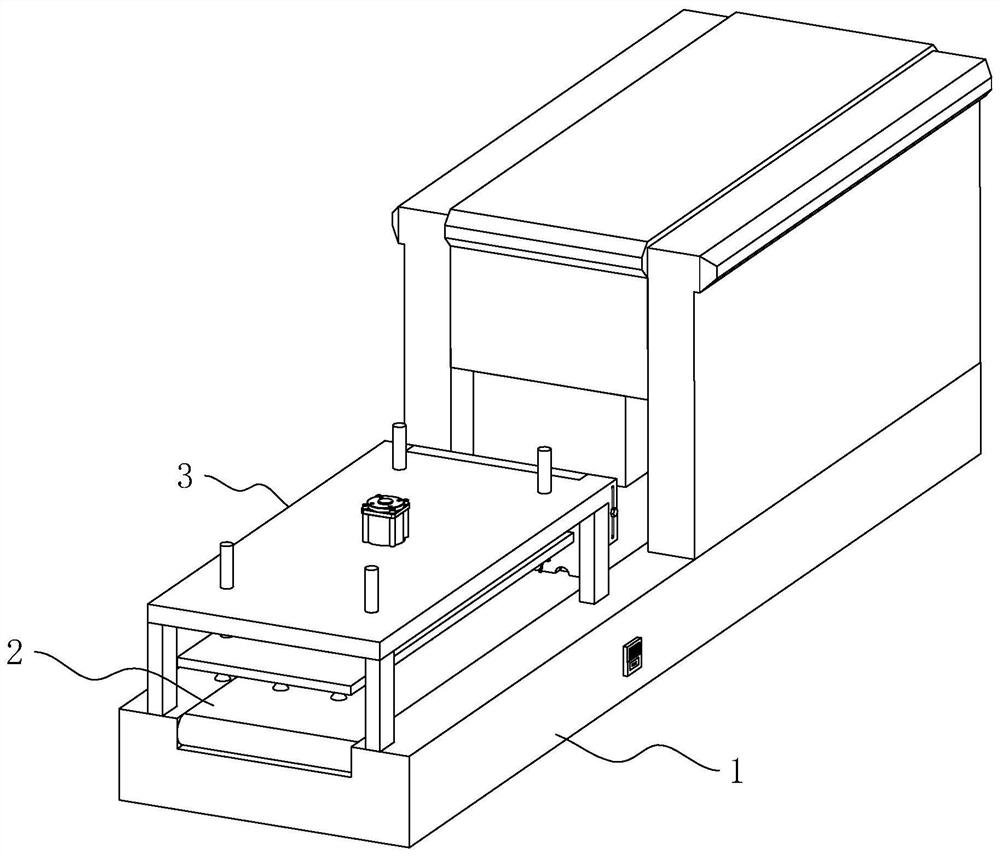

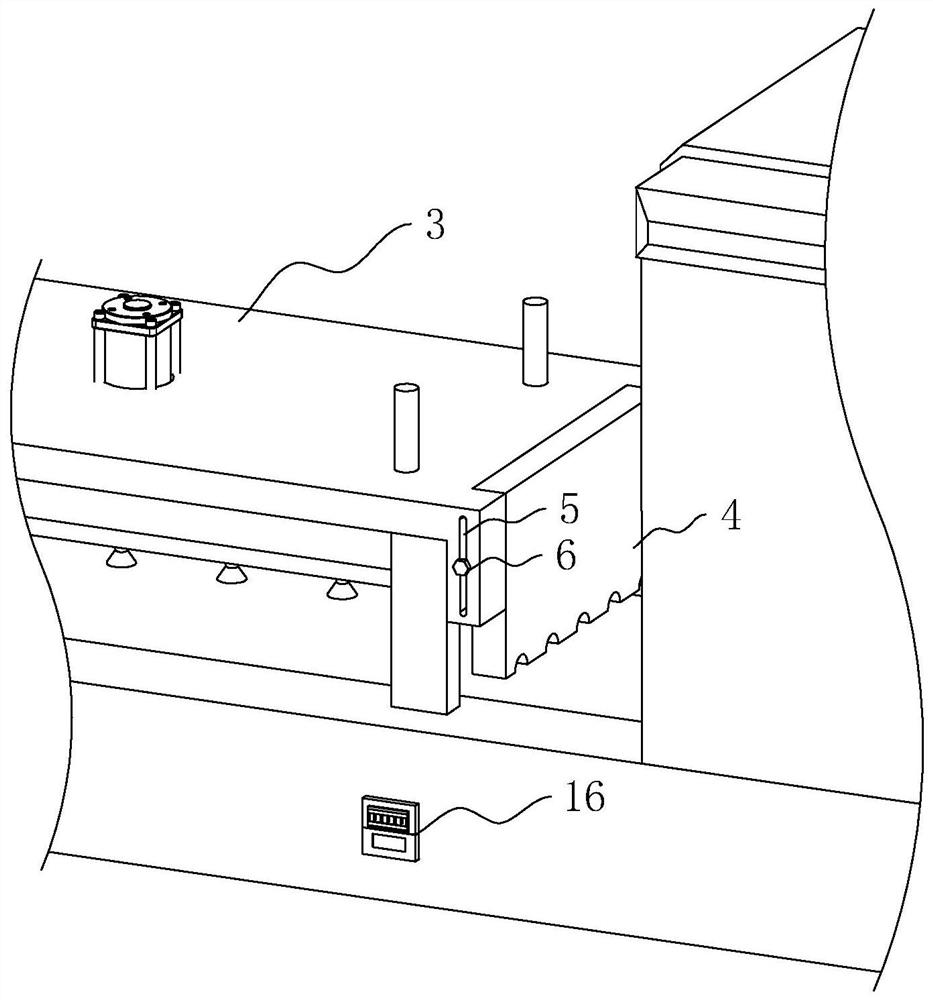

[0032] A feeding device for a die-cutting creasing machine, such as figure 1 , 2 As shown, it includes workbench 1, on which a feeding conveyor belt 2 is installed, on which workbench 1 is fixed a pressing bracket 3 located above the feeding conveyor belt 2, on which the end of the pressing bracket 3 close to the die-cutting station is installed There is a material blocking plate 4, and there is a feeding gap for a single corrugated cardboard to pass between the material blocking plate 4 and the feeding conveyor belt 2.

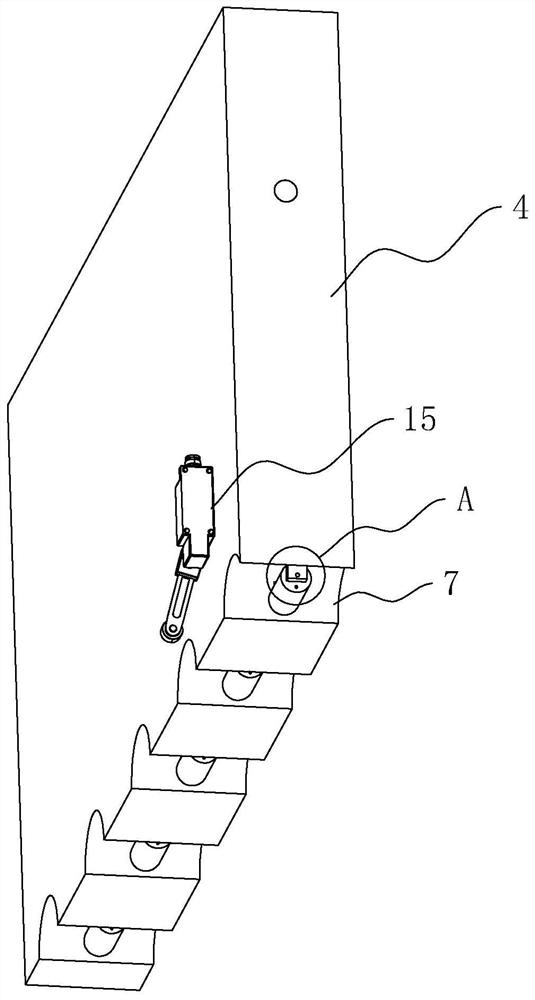

[0033] Such as figure 2 As shown, both sides of the pressing bracket 3 are provided with a waist-shaped hole 5 extending toward the direction of the feed conveyor belt 2, and the waist-shaped hole 5 is equipped with an adjusting bolt 6 that is threadedly connected with the material blocking plate 4, and the adjustment bolt 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com