Free fall simulator cooling system

By designing the cooling system in the closed pressure chamber in the free-fall simulator, the problems of condensation droplets splashing and noise are solved, user comfort and cooling efficiency are improved, and the maintenance process is simplified.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

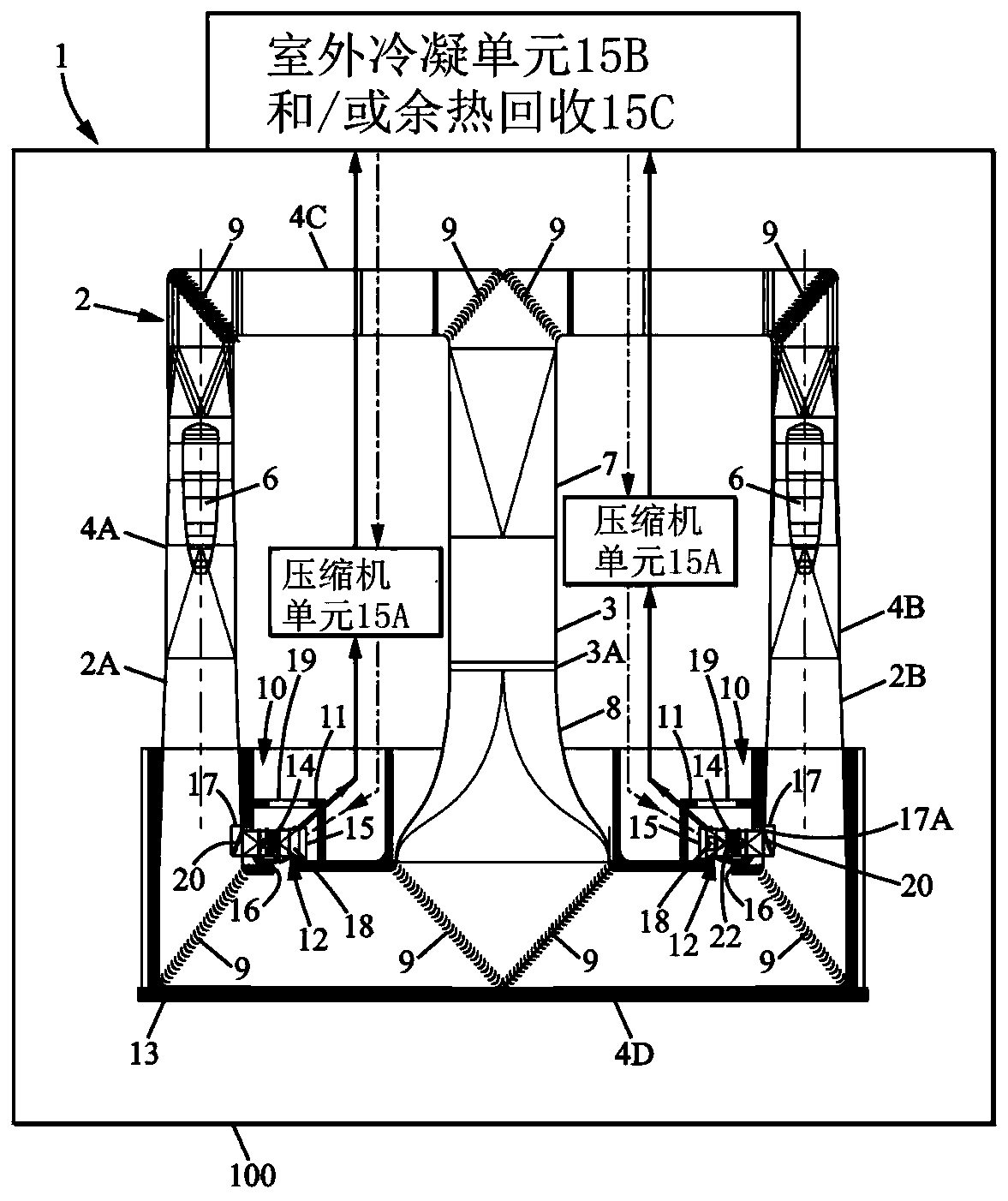

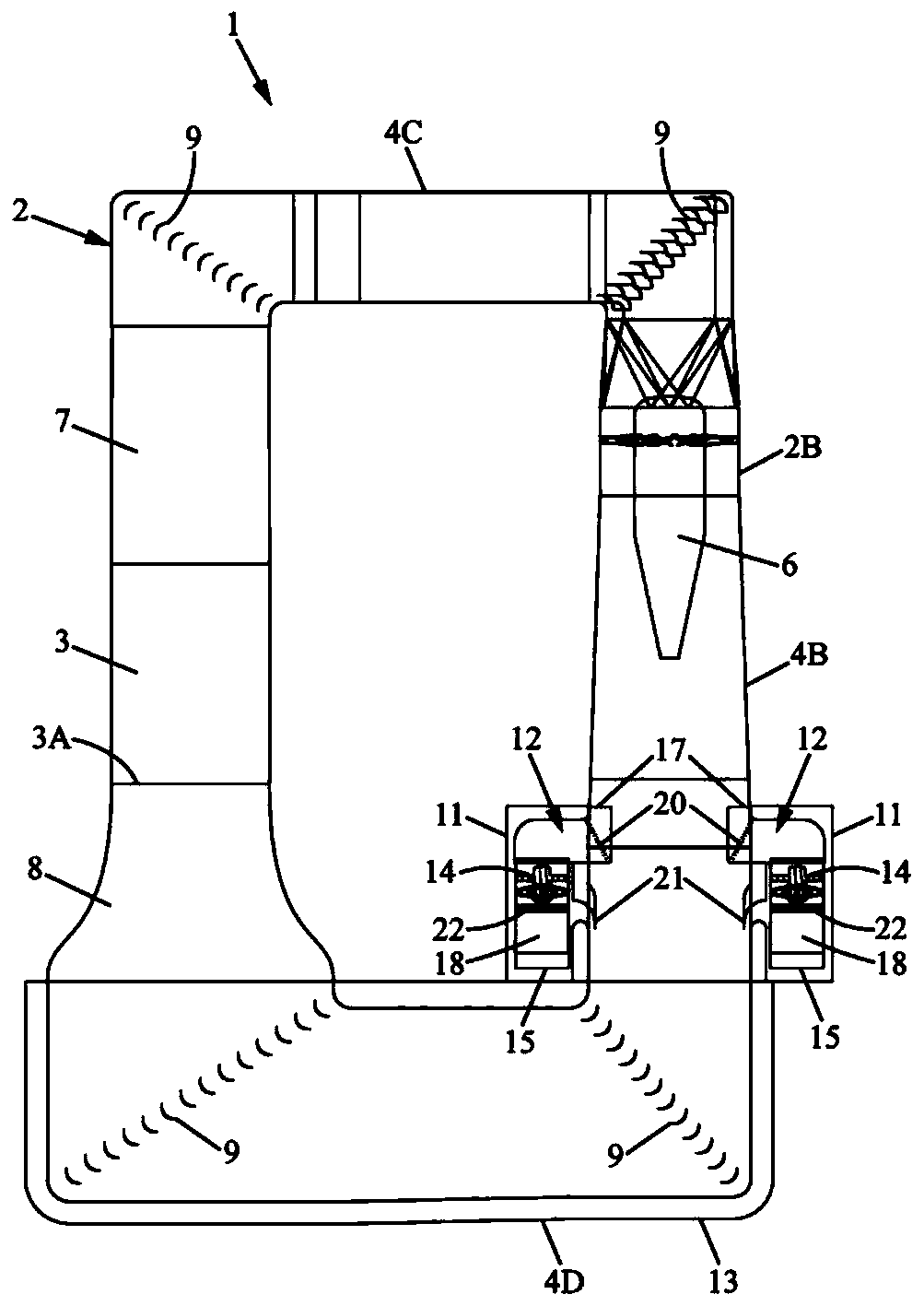

[0037] figure 1 A free fall simulator according to claim 1 shows an example of a free fall simulator 1 . A free fall simulator 1 is installed in a building 100 .

[0038] according to figure 1 The free fall simulator includes a flight chamber 3 into which the user of the simulator 1 can enter. At the bottom of the flight chamber 3 is installed a safety net 3A (for example, made of wire) which serves as a floor of the flight chamber 3 . Air flows through the net 3A from bottom to top, affecting upwardly the lifting of the user of the simulator 1, the force of the upwardly flowing air counteracting the force of gravity acting on the user.

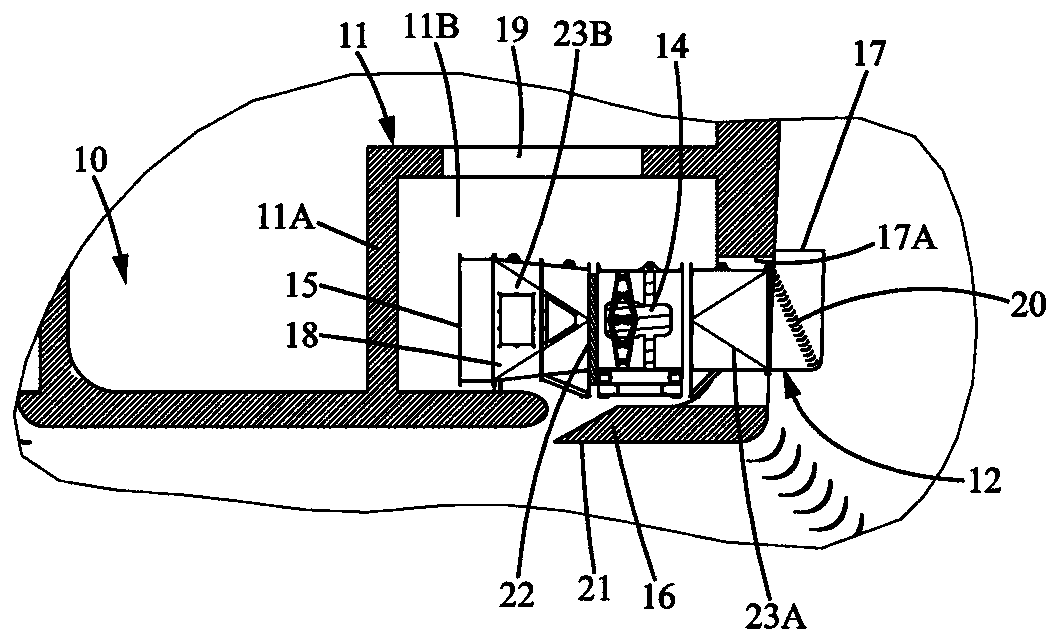

[0039] The rest of the simulator 1 connected to the flight chamber 3 and through which the air flows is described as a wind tunnel system 2 . The wind tunnel system 2 and the flight chamber 3 together constitute a circulating wind tunnel. From the flight chamber 3 upwards, in the direction of the air flow, the wind tunnel system 2 compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com