PETG and PVC composite decoration material and preparation method thereof

A PVC material and decorative material technology, applied in the field of decorative materials, can solve problems such as insufficient operating conditions, poor thickness, poor flattening, etc., and achieve good mechanical properties, good wear resistance, and good flattening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

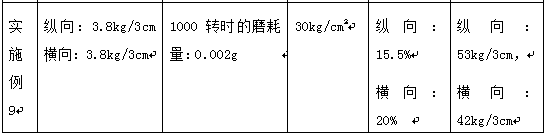

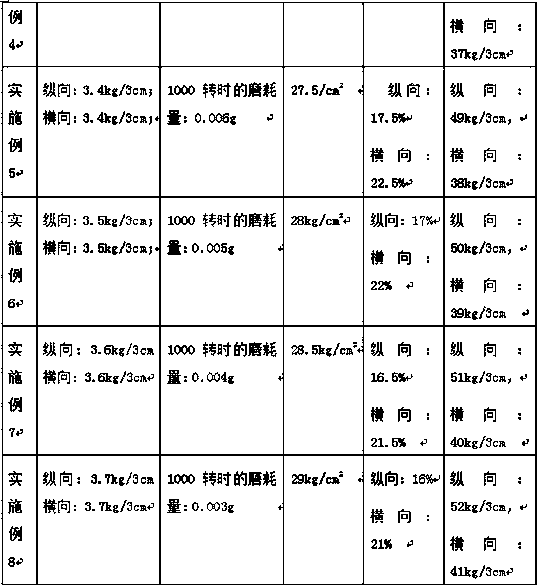

Examples

Embodiment 1

[0044] A preparation method of PETG and PVC composite decorative material, comprising the following steps:

[0045] PETG surface layer preheating step: preheat the PETG material through the super mirror roller, control the temperature at 130°C, and obtain the preheated PETG material;

[0046] PVC bottom layer preheating step: preheat the PVC material through the bright roller, control the temperature at 145°C, and obtain the preheated PVC material;

[0047] Composite step: the preheated PETG material and the preheated PVC material are pasted together, and then hot-pressed through a calender, and the temperature is controlled at 170°C to obtain a composite material layer composed of a PETG surface layer and a PVC bottom layer;

[0048] Cooling step: After cooling the composite material layer, control the cooling temperature to 16°C to obtain a PETG and PVC composite decoration material; control the thickness of the PETG surface layer to 0.10mm, and control the thickness of the ...

Embodiment 2

[0052] A preparation method of PETG and PVC composite decorative material, comprising the following steps:

[0053] PETG surface layer preheating step: preheat the PETG material through the super mirror roller, and control the temperature at 120°C to obtain the preheated PETG material;

[0054] PVC bottom layer preheating step: preheat the PVC material through the bright roller, control the temperature at 140°C, and obtain the preheated PVC material;

[0055] Composite step: the preheated PETG material and the preheated PVC material are pasted together, and then hot-pressed through a calender, and the temperature is controlled at 160°C to obtain a composite material layer composed of a PETG surface layer and a PVC bottom layer;

[0056] Cooling step: After cooling the composite material layer, control the cooling temperature to 16°C to obtain a PETG and PVC composite decoration material; control the thickness of the PETG surface layer to 0.07mm, and control the thickness of th...

Embodiment 3

[0060] A preparation method of PETG and PVC composite decorative material, comprising the following steps:

[0061] PETG surface layer preheating step: preheat the PETG material through the super mirror roller, and control the temperature at 125°C to obtain the preheated PETG material;

[0062] PVC bottom layer preheating step: preheat the PVC material through the bright roller, control the temperature at 142°C, and obtain the preheated PVC material;

[0063] Composite step: the preheated PETG material and the preheated PVC material are pasted together, and then hot-pressed through a calender, and the temperature is controlled at 165°C to obtain a composite material layer composed of a PETG surface layer and a PVC bottom layer;

[0064] Cooling step: After cooling the composite material layer, control the cooling temperature to 16°C to obtain a PETG and PVC composite decoration material; control the thickness of the PETG surface layer to 0.08mm, and control the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com