A kind of environment-friendly concrete and preparation method thereof

An environmentally friendly concrete and metal technology, applied in the field of building materials, can solve the problems of poor environmental protection, vehicles slipping, easy to fall into pits, etc., and achieve the effects of improving environmental protection, improving ecological environmental protection, and improving permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: A kind of environment-friendly concrete, each component and its corresponding weight ratio are shown in Table 1, and are prepared through the following steps:

[0048] Step 1, uniformly mixing cement, mineral powder, fly ash, sand, and crushed stone in a corresponding weight ratio to obtain a dry mix;

[0049] Step 2, mixing and dispersing water, water reducing agent, and metal steel balls with a diameter of 12 cm and a porosity of 40% to obtain a mixed solution with metal steel balls;

[0050] Step 3: Add the mixed liquid with metal steel balls into the dry mix, stir and mix evenly to obtain the environment-friendly concrete.

[0051] The water reducer in this embodiment is polycarboxylate water reducer, YB-C polycarboxylate high performance water reducer purchased from Hunan Yibao Building Materials Co., Ltd.

Embodiment 2-6

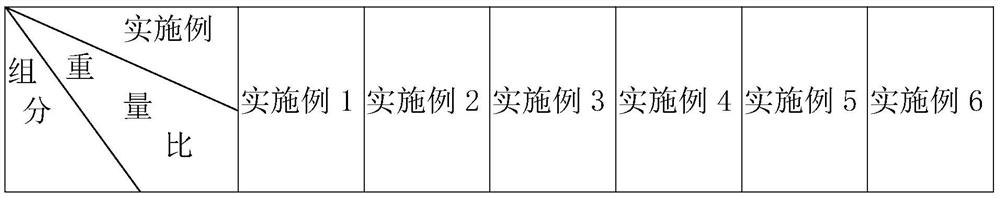

[0052] Example 2-6: An environmentally friendly concrete, the difference from Example 1 is that each component and its corresponding weight ratio are shown in Table 1.

[0053] Each component and its weight ratio in Table 1 embodiment 1-6.

[0054]

[0055]

Embodiment 7

[0056] Embodiment 7: A kind of environment-friendly concrete, the difference with embodiment 3 is that the metal steel wire ball is subjected to fluorination treatment, and the fluorination treatment includes the following steps:

[0057] (1) metal steel wire balls are put into the reactor with fluorinated liquid, the fluorinated liquid of the present embodiment is purchased from the 3MTM NovecTM7100DL fluorinated liquid of Minnesota Mining and Manufacturing Company;

[0058] (2) Feed an inert gas into the reactor, nitrogen is preferred in this embodiment, helium, xenon or argon can be used in other embodiments, the control pressure is 40Mpa; the temperature of the reactor is controlled to be 190°C, after reaching the set temperature , react for 25h;

[0059] (3) Pressure relief, wait for the reaction kettle to cool down, take out the metal steel balls, and obtain the metal steel balls after the fluorination treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com