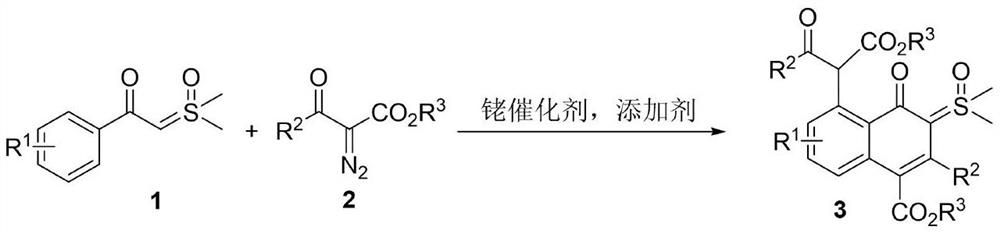

Synthesis of 4-oxo-5-(arylformyl acetate-2-yl)naphthalene-sulfoxide ylide hybrids

A technology of arylformyl acetate and arylformyl sulfoxide, which is applied in the field of synthesis of 4-oxo-5-naphthalene-sulfoxide ylide hybrid, and achieves simple operation process, high atom economy, and scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

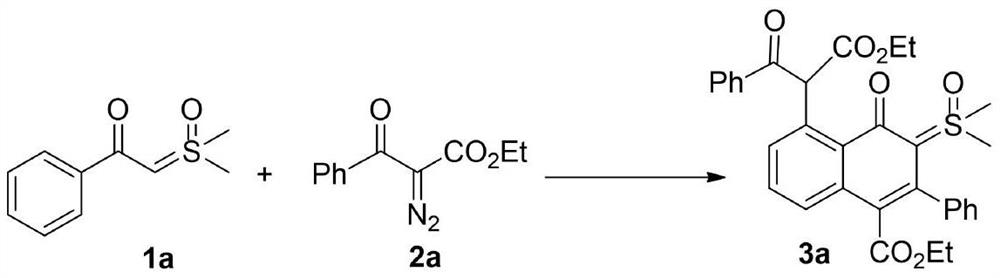

Embodiment 1

[0020]

[0021] 1a (0.5mmol, 98mg), 2a (0.5mmol, 109mg), silver hexafluoroantimonate (27.5mg, 0.08mmol), [RhCp*Cl 2 ] 2 (12mg, 0.02mmol) and 1,2-dichloroethane (3mL), stirred at 80°C for 24h under nitrogen atmosphere. TLC detects that in addition to the main product, there is also a major impurity point generated. Then the reaction system was cooled to room temperature, 10 mL of saturated brine was added to quench the reaction, extracted with ethyl acetate (10 mL×3), the organic phases were combined, and washed with anhydrous Na 2 SO 4 After drying, the solvent was spin-dried and separated by silica gel column (petroleum ether / ethyl acetate=1 / 1) to obtain the product 3a (64 mg, 23%) as a pale yellow solid. The characterization data of this compound are as follows: 1 H NMR (600MHz, CDCl 3 )δ: 0.80(t, J=7.2Hz, 3H), 1.17(t, J=7.2Hz, 3H), 3.56(s, 3H), 3.58(s, 3H), 3.81(q, J=7.2Hz, 2H), 4.17(q, J=7.2Hz, 2H), 7.08(d, J=7.2Hz, 1H), 7.24-7.32(m, 7H), 7.36-7.42(m, 2H), 7.54(d,...

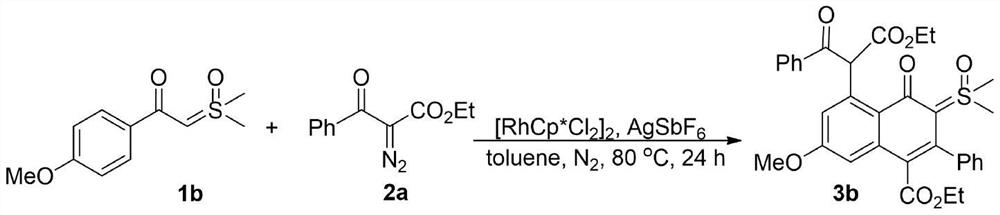

Embodiment 2

[0023] 1a (0.5mmol, 98mg), 2a (0.5mmol, 109mg), silver hexafluoroantimonate (27.5mg, 0.08mmol), [RhCp*Cl 2 ] 2 (12mg, 0.02mmol) and tetrahydrofuran (3mL), stirred at 80°C for 24h under nitrogen atmosphere. TLC detects that in addition to the main product, there is also a major impurity point generated. Then the reaction system was cooled to room temperature, 10 mL of saturated brine was added to quench the reaction, extracted with ethyl acetate (10 mL×3), the organic phases were combined, and washed with anhydrous Na 2 SO 4 After drying, the solvent was spin-dried and separated by silica gel column (petroleum ether / ethyl acetate=1 / 1) to obtain product 3a (39 mg, 14%) as a pale yellow solid.

Embodiment 3

[0025] 1a (0.5mmol, 98mg), 2a (0.5mmol, 109mg), silver hexafluoroantimonate (27.5mg, 0.08mmol), [RhCp*Cl 2 ] 2 (12mg, 0.02mmol) and acetonitrile (3mL), stirred at 80°C for 24h under nitrogen atmosphere. TLC detects that in addition to the main product, there is also a major impurity point generated. Then the reaction system was cooled to room temperature, 10 mL of saturated brine was added to quench the reaction, extracted with ethyl acetate (10 mL×3), the organic phases were combined, and washed with anhydrous Na 2 SO 4 After drying, the solvent was spin-dried and separated by silica gel column (petroleum ether / ethyl acetate=1 / 1) to obtain product 3a (28 mg, 10%) as a pale yellow solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com