Method for controlling crystallization of polylactic acid through alternating electromagnetic field

An alternating electromagnetic field and polylactic acid technology, which is applied in the field of polylactic acid crystallization modification, can solve the problems of affecting molecular chains, limited influence of polylactic acid crystallization, and inability to actively control polymer molecular chains, etc. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for controlling polylactic acid crystallization by an alternating electromagnetic field, the method comprising the steps of:

[0024] (1) Weigh 0.99g of L-polylactic acid (4032D, Nature works, USA) and dissolve it in 10ml of chloroform, add 0.01g of ferric oxide particles (3-10nm) and stir evenly, drop it onto a glass slide to evaporate the solvent, and get Polylactic acid / ferric oxide composite film material;

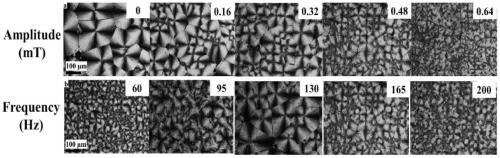

[0025] (2) Heat the polylactic acid / ferroferric oxide composite material in step (1) to 123°C in an alternating electromagnetic field for crystallization, by adjusting the intensity and frequency of the alternating electromagnetic field (the intensity is 0~0.64mT; ~200 Hz) to control the isothermal crystallization behavior of PLA at 123 °C. First, the frequency is controlled to 165 Hz, and the intensity of the alternating magnetic field is adjusted between 0 and 0.64 mT to obtain the isothermal crystal POM photo of polylactic acid at 123 °C; then the m...

Embodiment 2

[0029] A method for controlling polylactic acid crystallization by an alternating electromagnetic field, the method comprising the steps of:

[0030] (1) Weigh 0.97g of L-polylactic acid and dissolve it in 10ml of chloroform, add 0.03g of iron ferric oxide particles (3~10nm) and stir evenly, drop it onto a glass slide to evaporate the solvent, and obtain polylactic acid / ferric iron tetroxide composite materials;

[0031] (2) Heat the polylactic acid / ferroferric oxide composite material in step (1) to 123°C in an alternating electromagnetic field to crystallize for 30 minutes, adjust the strength of the alternating electromagnetic field to 0.16 millitesla and the frequency to 165 Hz to control the polylactic acid crystallization behavior.

[0032] Test its crystallinity by DSC method, the results are shown in Table 1 and Figure 4 .

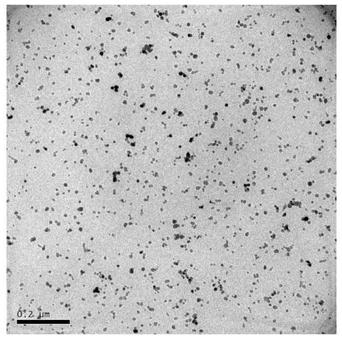

[0033] The TEM photograph that this embodiment prepares composite material sees image 3 , it can be seen from the figure that ferric oxide i...

Embodiment 3

[0035] A method for controlling polylactic acid crystallization by an alternating electromagnetic field, the method comprising the steps of:

[0036] (1) Weigh 97g of racemic polylactic acid, add 3g of ferric oxide particles (3-10 nanometers) and stir evenly, and melt, blend and extrude on a twin-screw extruder to obtain polylactic acid / ferric oxide composite material;

[0037](2) The obtained polylactic acid / iron tetroxide composite material was heated to 123°C in an alternating electromagnetic field for crystallization for 30 minutes, and the intensity of the alternating electromagnetic field was adjusted to 0.48 millitesla and the frequency was 130 Hz to control the crystallization behavior of polylactic acid .

[0038] Test its crystallinity by DSC method, the results are shown in Table 1 and Figure 4 .

[0039] The DSC result of table 1 embodiment 1~3

[0040]

[0041] The following conclusions can be drawn from the above examples: the size and crystallinity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com