Device and method for regulating and controlling pH and reinforcing hydrogen production through in-situ hydrogen oxidation method

An oxidation method, hydrogen technology, applied in the direction of electrolysis components, cells, electrolysis process, etc., can solve the problem of excessive pH rise, and achieve the effects of reducing operating costs, convenient operation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

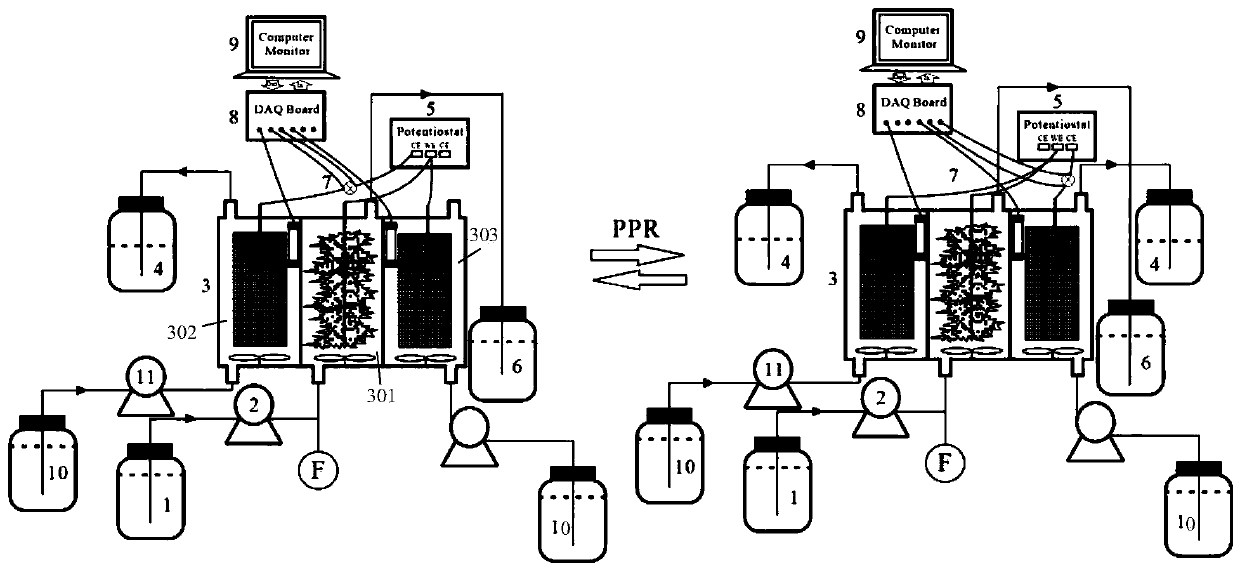

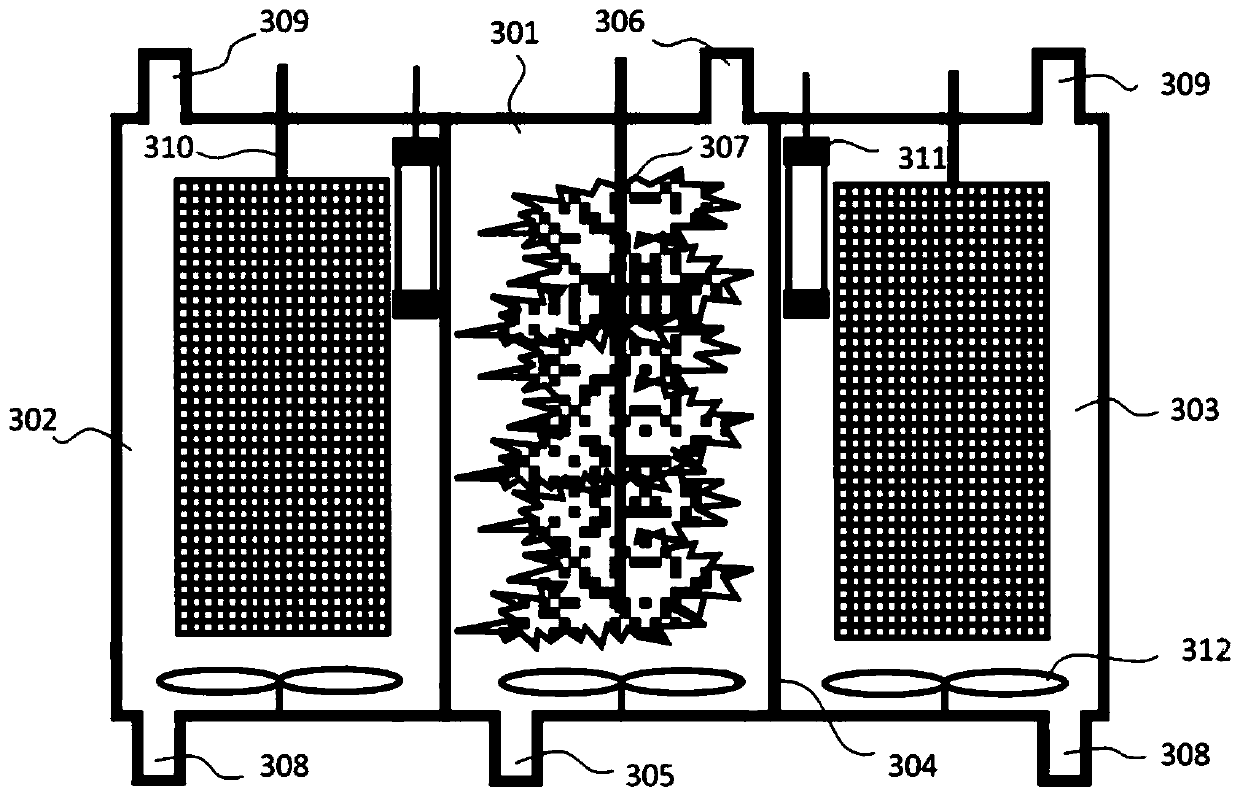

[0024] Such as figure 1 , figure 2 In this embodiment, the in-situ hydrogen oxidation method adjusts pH and enhances hydrogen production. The device includes a microbial electrolytic cell 3, which includes two cathode chambers and an anode chamber 301. The volume of the anode chamber and the cathode chamber is set according to actual conditions. In this embodiment, the volume of the anode compartment 301 is 90 mL, and the volume of the cathode compartment is 150 mL. To facilitate the understanding of the present invention, the two cathode chambers are named the first cathode chamber 302 and the second cathode chamber 303, respectively. The anode chamber 301 is provided between the two cathode chambers, between the anode chamber and the first cathode chamber 302, and The anode chamber and the second cathode chamber 303 are separated by a cation exchange membrane 304. The cation exchange membrane can be an existing product, for example, the product of the following company: Mem...

Embodiment 2

[0035] The catholyte uses 50mM PBS, and the rest of the device structure is the same as in Example 1.

[0036] The method of applying the above-mentioned device to adjust pH and enhance hydrogen production by in-situ hydrogen oxidation method includes the following steps:

[0037] Connect the anode 307 of the anode chamber to the positive pole of the voltage stabilizer 5, the cathode of the first cathode chamber 302 connects the resistor 7 (1ohm) to the negative pole of the stabilizer 5, and the cathode of the second cathode chamber 303 connects to the voltage stabilizer 5. Connect to the positive pole.

[0038] The water inlet pump 2 continuously pumps the anode electrode liquid in the anode water inlet tank 1 into the anode chamber 301, and the water outlet 306 collects the water to the anode water outlet tank 6 with a hydraulic residence time of 10h. The water pump 11 pumps the electrolyte in the electrolyte tank 10 into the first cathode chamber 302 and the second cathode chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com