Thermo-sensitive coating material, thermo-sensitive diaphragm and preparation method and application of thermo-sensitive diaphragm

A coating material, heat-sensitive technology, applied in the direction of electrical components, circuits, battery pack components, etc., can solve the problem of poor overcharge safety performance of the diaphragm, achieve good electrolyte resistance and pressure resistance, and protect overcharge safety , Improve the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

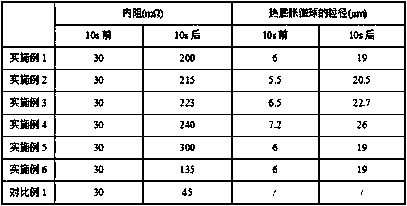

Embodiment 1

[0056] A heat-sensitive coating material, comprising the following components by mass percentage: 4% of polyacrylate binder, 85.5% of alumina, 0.5% of sodium polyacrylate, and 10% of heat-expandable microspheres of polyacrylic acid matrix.

[0057] A heat-sensitive diaphragm and a preparation method thereof, comprising the steps:

[0058] (1) Slurry preparation: add 0.5 parts by mass of sodium polyacrylate to 65.5 parts by mass of deionized water, stir at 1500 r / min for 30 min, then add 85.5 parts by mass of alumina and 10 parts by mass of polyacrylic acid matrix Heat-expandable microspheres were stirred at a high speed of 3000 r / min for 60 min, finally added 4 parts by mass of polyacrylate binder, stirred at a medium speed of 1500 r / min for 60 min, and then stirred at a low speed of 500 r / min for 30 min to degas , and then pass through a screen to obtain a heat-sensitive coating material.

[0059] (2) Coating: A heat-sensitive coating material was coated on one side of the 1...

Embodiment 2

[0061] A heat-sensitive coating material, comprising the following components by mass percentage: 4% of polyacrylate binder, 85.5% of alumina, 0.5% of sodium polyacrylate and 10% of heat-expandable microspheres of hyperbranched polypropylene matrix.

[0062] A heat-sensitive diaphragm and preparation method thereof:

[0063] The difference between this example and Example 1 is that in step (1) of this example, the thermally expandable polymer microspheres are hyperbranched polypropylene matrix thermally expandable microspheres;

[0064] The consumption of other raw materials and operation steps are the same as those in Example 1.

Embodiment 3

[0066] A heat-sensitive coating material, comprising the following components by mass percentage: 4% of polyacrylate binder, 85.5% of alumina, 0.5% of sodium polyacrylate and 10% of heat-expandable microspheres of hyperbranched polyethylene matrix.

[0067] A heat-sensitive diaphragm and preparation method thereof:

[0068] The difference between this example and Example 1 is that in step (1) of this example, the heat-expandable polymer microspheres are hyperbranched polyethylene matrix heat-expandable microspheres;

[0069] The consumption of other raw materials and operation steps are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com