Low molecular liquid rubber preparation device

A liquid rubber and preparation device technology, which is applied in the field of low molecular liquid rubber production and preparation, can solve the problems of poor performance of the output product, non-continuous production, long reaction time, etc., and achieve small equipment footprint, easy operation, and finished products The effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

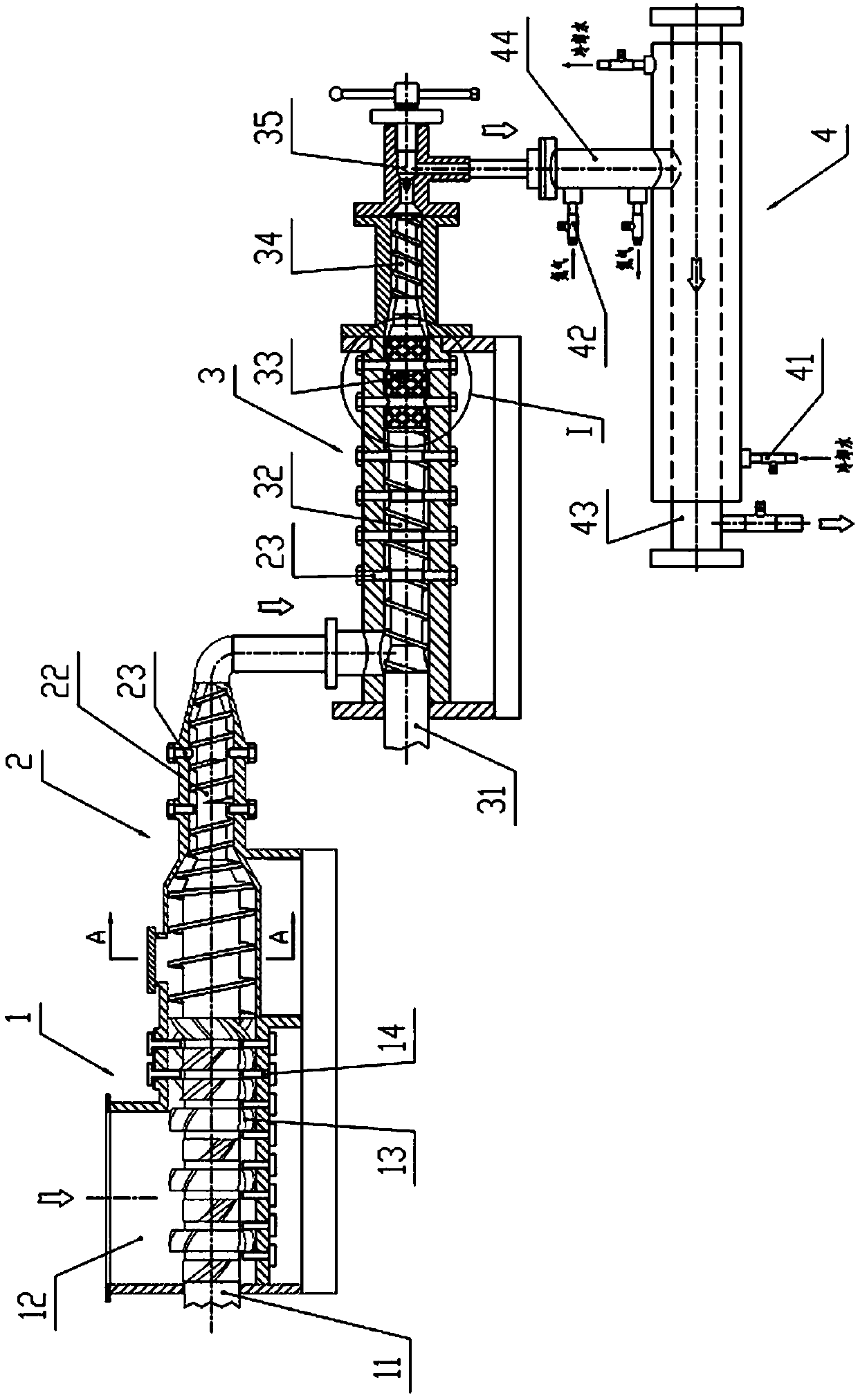

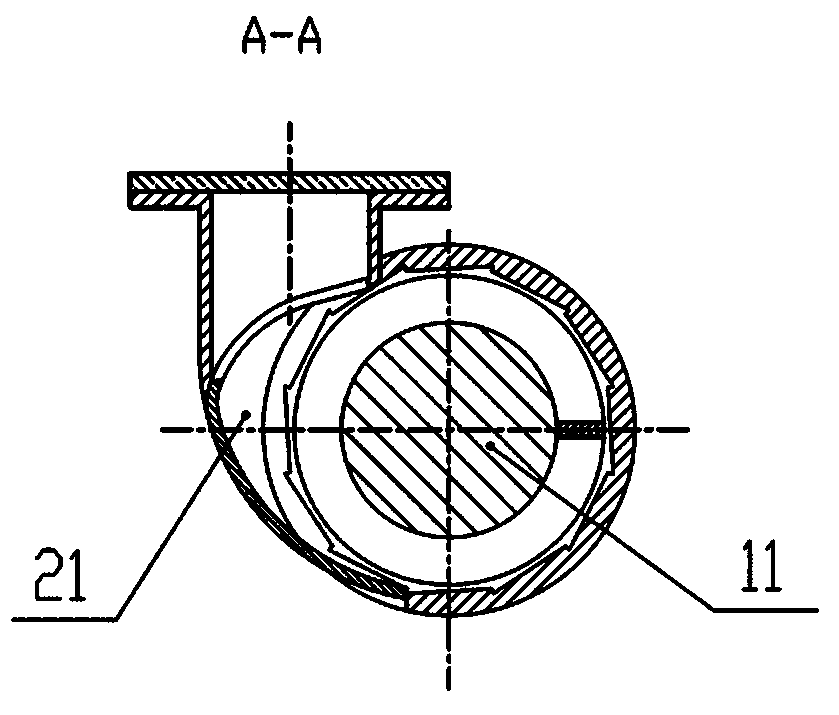

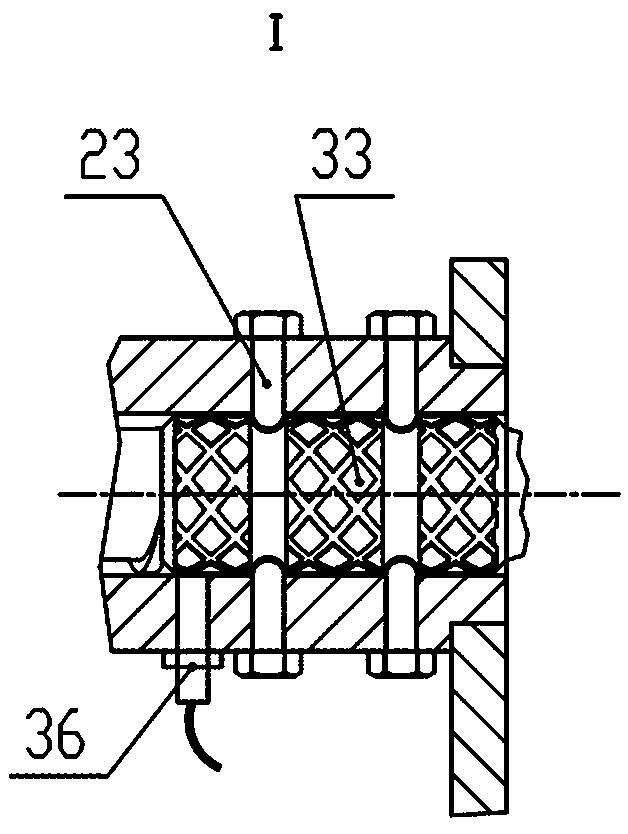

[0025] The specific embodiment of the present invention sees Figure 1 to Figure 3 , a low-molecular-weight liquid rubber preparation device, according to the process flow, it sequentially includes a solid rubber crushing section 1, a rubber heating and softening section 2, a rubber high-temperature degradation section 3 and a liquid rubber cooling section 4, and the solid rubber crushing section 1 and rubber heating The softening section 2 shares an extruding screw 11. The solid rubber crushing section 1 can crush large blocks or flakes of rubber into small particles. The side of the spiral cylinder of the rubber heating and softening section 2 is provided with an outwardly bulging heating chamber 21. Under the action of the extrusion screw 11, the small granular rubber is temporarily stored, accumulated, extruded and softened by heating in the heating chamber 21. The outlet end of the rubber heating and softening section 2 is provided with a small outer diameter extrusion sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com