High-concentration COD wastewater recycling treatment system and method

A high-concentration and resource-based technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. Realize the effect of recycling, no change in adsorption efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

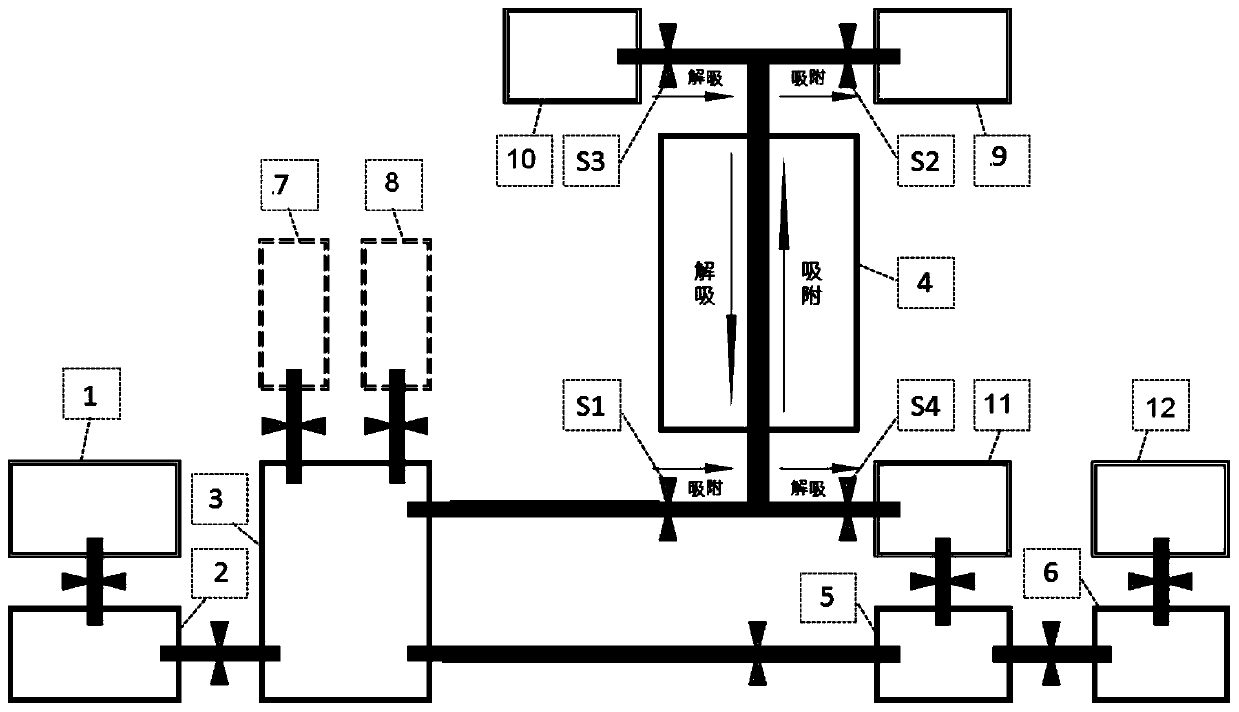

[0036] An embodiment of the system for the resourceful treatment of high-concentration COD wastewater according to the present invention, the structural diagram is as follows figure 1 As shown, the system for resourceful treatment of high-concentration COD wastewater described in this embodiment includes a filter device 2, an extraction device 3, a COD resin adsorption column 4, an acidification system 5, and an ultrafiltration device 6; the water inlet of the filter device 2 is connected to the The waste water storage tank 1 is connected, and the water outlet of the filter device 2 is connected with the waste water inlet of the extraction device 3; the extraction device 3 is provided with a waste water inlet, an extraction agent inlet, a stripping agent inlet, a raffinate outlet and The stripping liquid outlet, the COD resin adsorption column 4 is provided with an adsorption water inlet, an adsorption water outlet, a backwashing liquid inlet and a regenerated water outlet, the...

Embodiment 2

[0042] An embodiment of the method for resourceful treatment of high-concentration COD wastewater according to the present invention, the method for resourceful treatment of high-concentration COD wastewater described in this embodiment includes the following steps:

[0043] (1) Filter high-concentration COD wastewater;

[0044] (2), add extraction agent in the waste water after filtering and carry out extraction, obtain raffinate and loading organic phase;

[0045] (3), the raffinate is passed through the COD resin adsorption column to adsorb the COD substances in the waste water to obtain the waste water after adsorption; adding a stripping agent to the loaded organic phase to obtain a regenerated organic phase and a stripping liquid;

[0046] (4), adopt sodium hydroxide solution to backwash the COD resin adsorption column to obtain regenerated water;

[0047] (5), step (3) gained back extraction liquid and step (4) gained regenerated water are carried out acidification tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com