Patents

Literature

30 results about "Tobias acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tobias acid (2-amino-1-naphthalenesulfonic acid) is an organic compound with the formula C₁₀H₆(SO₃H)(NH₂). It is one of several aminonaphthalenesulfonic acids, which are derivatives of naphthalene containing both amine and sulfonic acid functional groups. It is a white solid, although commercial samples can appear otherwise. It is used in the synthesis of azo dyes such as C.I. Acid Yellow 19 and C.I. Pigment Red 49. It is prepared via the Bucherer reaction of 2-hydroxynaphthalene-1-sulfonic acid with ammonia and ammonium sulfite.

Method for preparing polar solvent soluble nano ferriferrous oxide granule

InactiveCN1775694AGood dispersionThe reaction process is simpleFerroso-ferric oxidesCross-linkHigh concentration

The invention relates to a controlling and resource recovering method for waste water in tobias acid production, adjusting the pH of the waste water and filtering, and making main organic matters in the waste water absorbed on resins by macroporous weakly basic resin and super-high cross-linking absorbing resin combination. And before processing, the waste water is puce, chroma of the waste water is 45000-5000mg / L, sulphonated tobias acid concentration of the waste water is 12000-15000mg / L, tobias acid and 2, 1-acid concentration of the e waste water is 6000-7000mg / L, COD concentration of the waste water is 45000-50000mg / Lú¼and after processing, the chroma is 10-50, sulphonated tobias acid concentration <500mg / L, the TuShi acid and 2, 1-acid concentration<50mg / L, and CODcr<1500mg / L. And the resins regenerate by de-absorption of liquid alkali and water. High concentration de-absorbing liquor returns to the aminating operation segment in the tobias acid producing process and low concentration de-absorbing liquor is used in the next de-absorbing operation.

Owner:SHANGHAI JIAO TONG UNIV

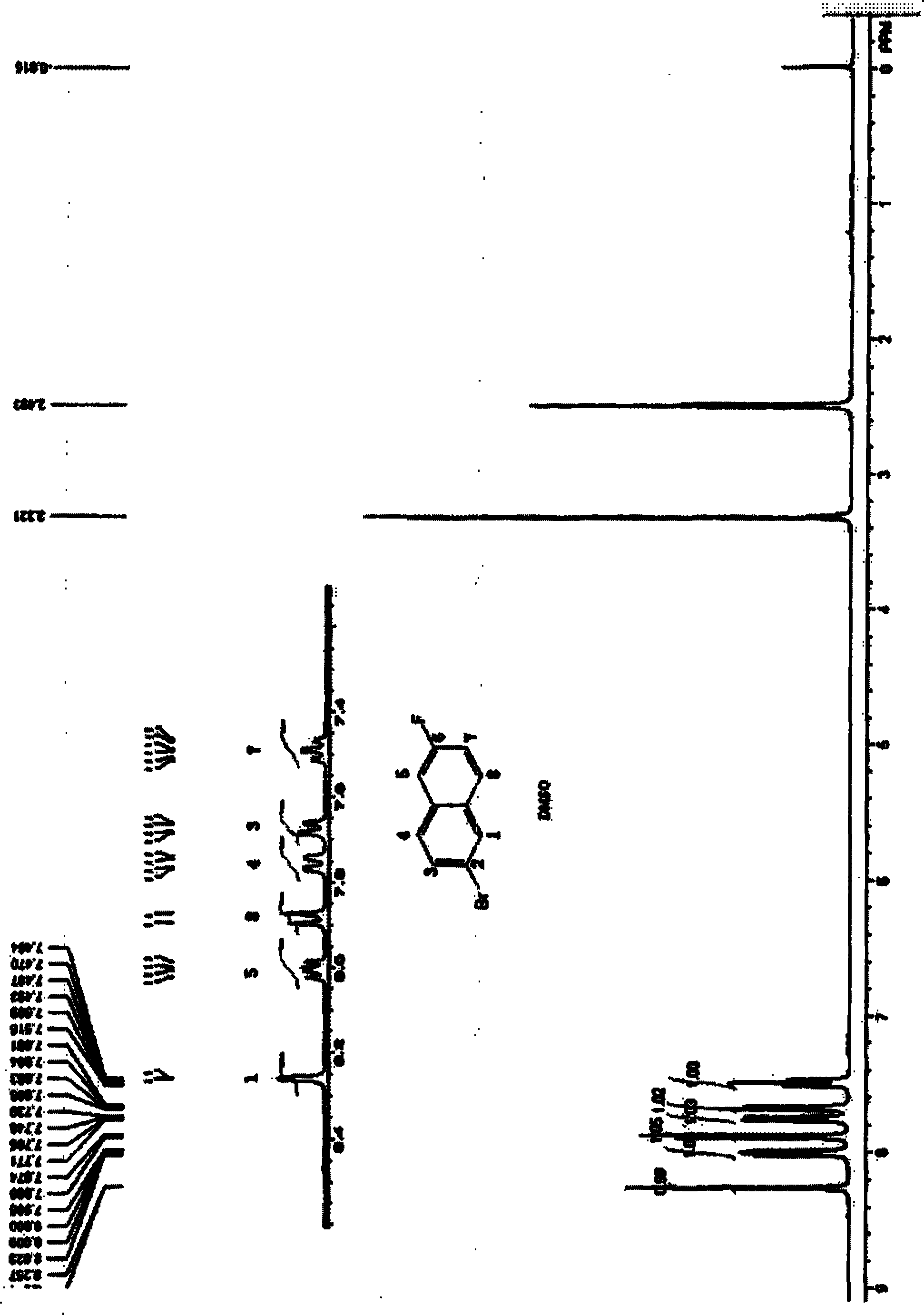

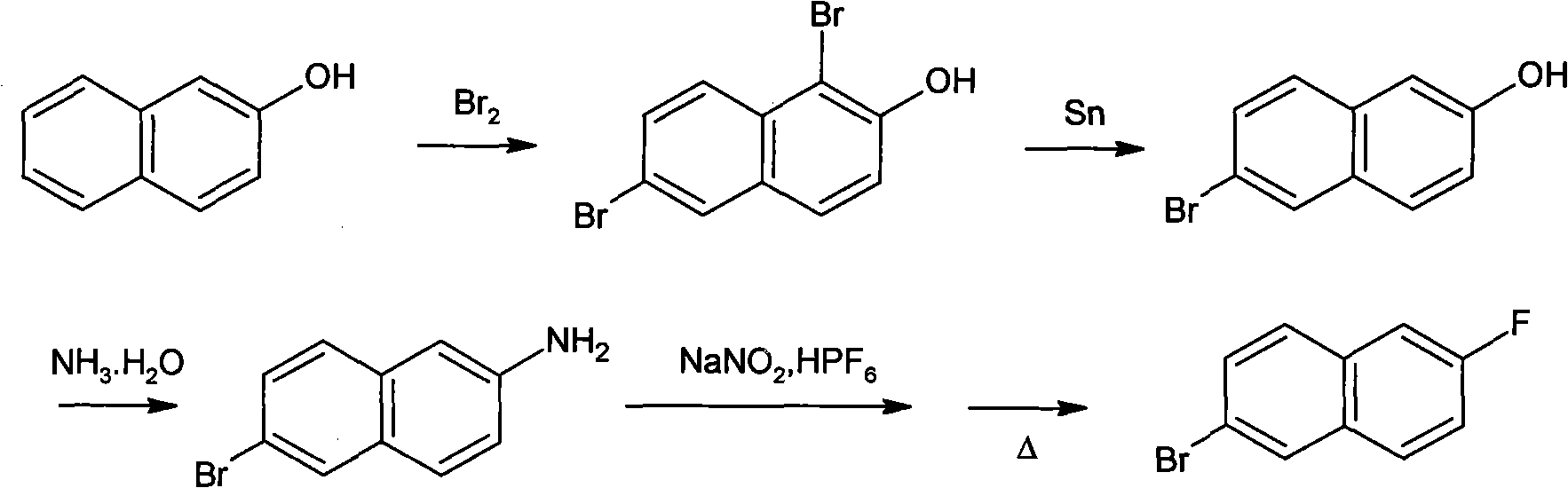

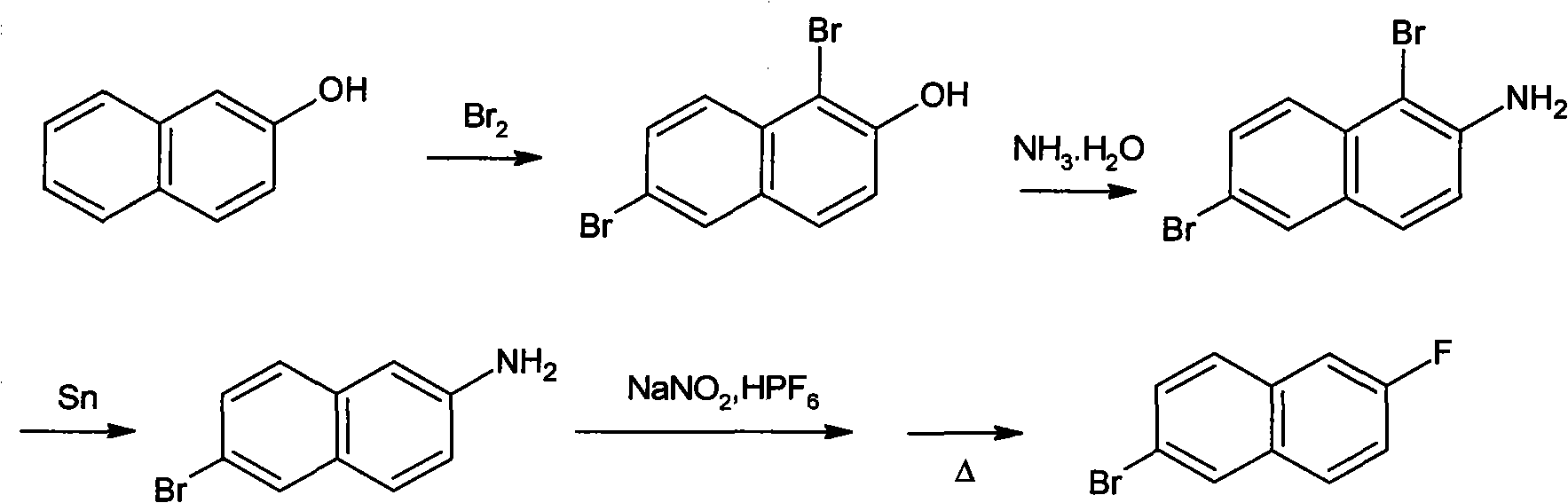

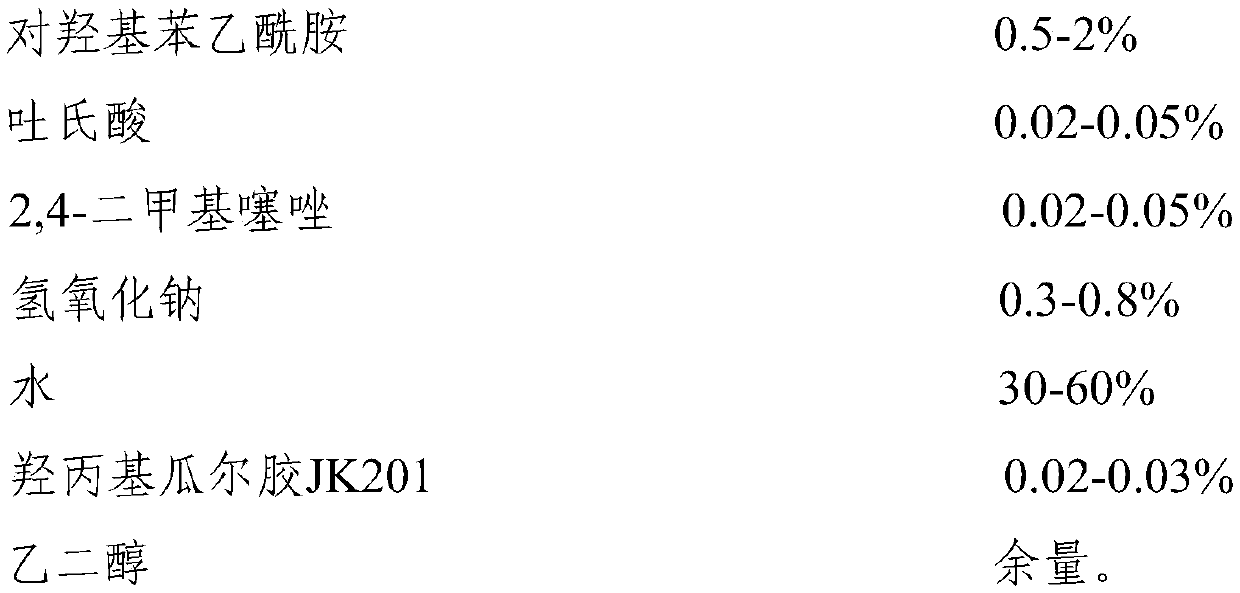

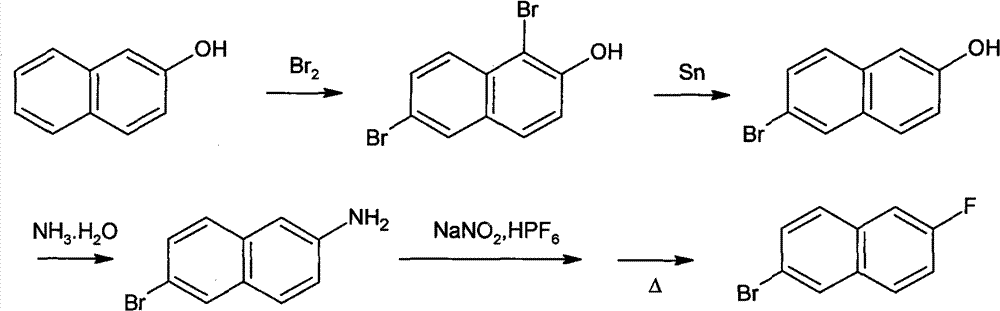

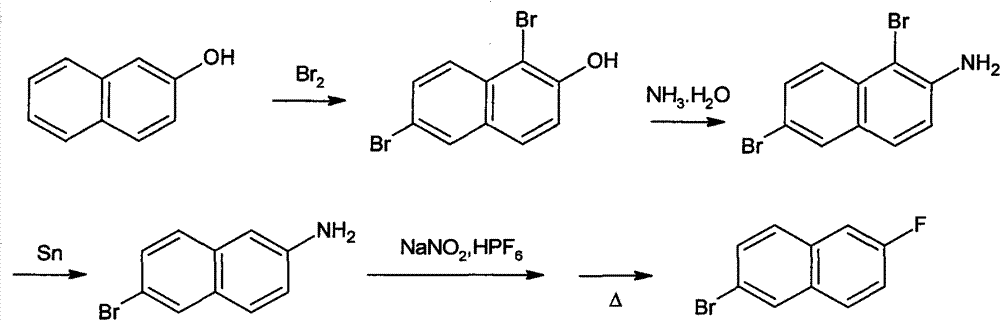

Preparation method of 2-bromo-6-fluoronaphthalene

InactiveCN101870636AShort synthetic routeMild conditionsOrganic compound preparationOrganic halogenationTobias acidNitrogen

The invention belongs to the technical field of pharmacy and relates to a preparation method of 2-bromo-6-fluoronaphthalene. In the method, tobias acid with low price is used as a starting material, and the 2-bromo-6-fluoronaphthalene as a target product is obtained through three steps of bromination-debromination, diazotization and thermal cracking and has high purity and stable quality. The synthesis process of the method only has three steps, thus the method has simple route, mild reaction condition and no need of high-pressure condition; and the fluoroboric acid which has low price and iseasy to obtain is used for generating a diazonium salt, thus the method has low cost and easy realization of industrialization.

Owner:DATANGHANGZHOU PHARMACHEM

Method for preparing tobias acid by effective components extracted from waste water of tobias acid production

InactiveCN101250141AImprove qualityOrganic chemistryOrganic compound preparationResource utilizationWater vapor

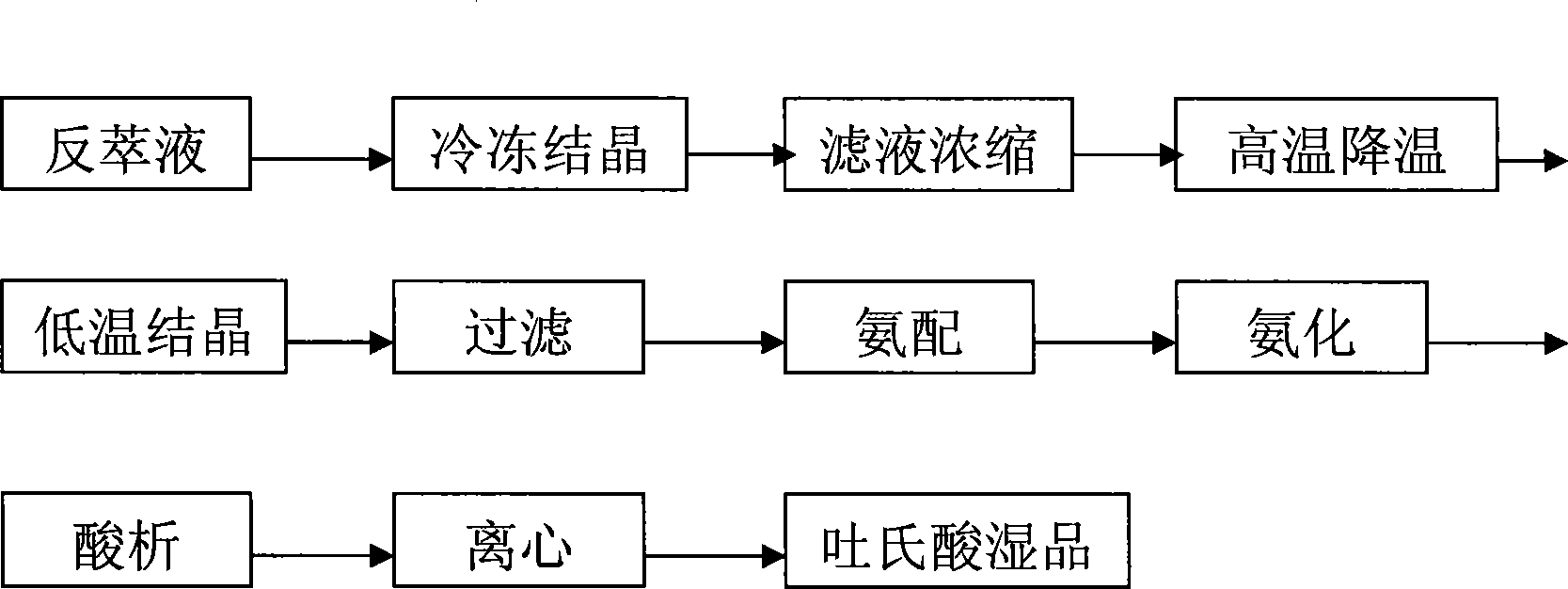

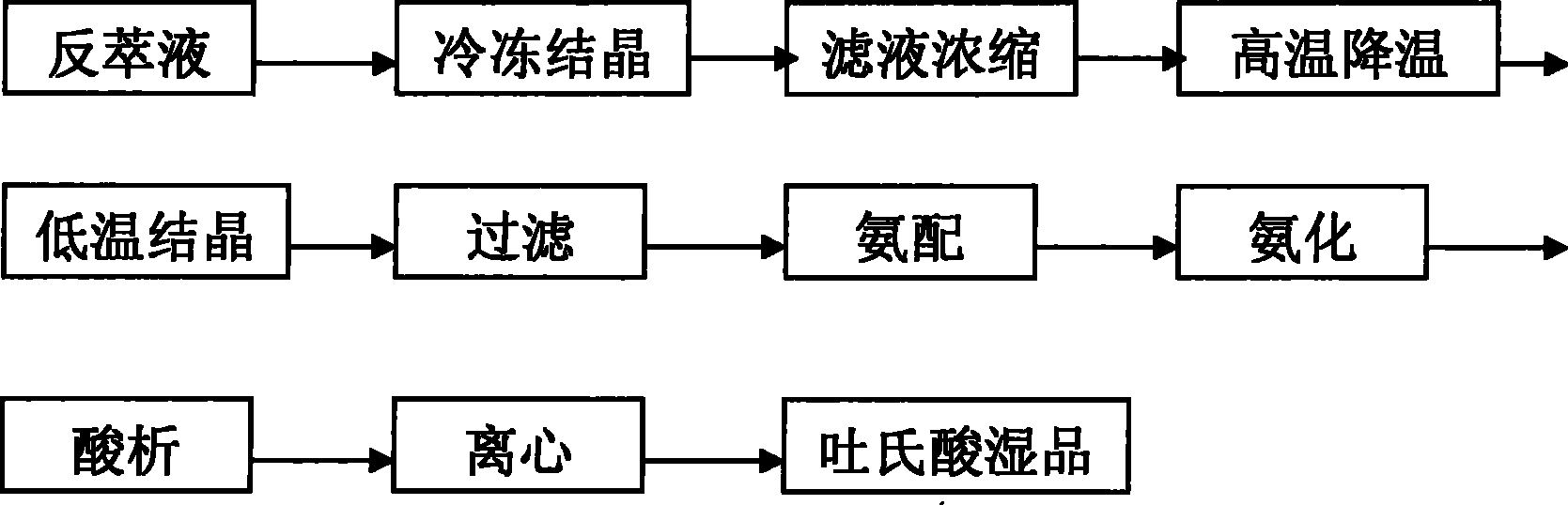

The invention relates to a method for extracting effective component from the waste water of the mother liquor of tobias acid production to produce tobias acid, belonging to the waste pollutant resource utilization technique of environment protection field. The invention resolves the problems of prior art which simply refluxes strip liquor as impurity accumulation to affect product quality. The method comprises cooling strip liquor to -2DEG C and 20DEG C in a kettle with a jacket, keeping the temperature for 3-12h, filtering out mirabilite, concentrating the denitration liquid in a distiller, discharging steam, evaporating out 35-50% of water content, reducing temperature, precipitating at least 95% organic crystal at 35-50DEG C, centrifugally filtering to obtain hydroxyl sodium tobias acid and some wet product of sodium tobias acid, dissolving the wet product and processing ammonia complex, feeding into an ammoniation reactor for ammoniation, increasing temperature to 140-160DEG C, keeping temperature for 6-8h, discharging ammonia, reducing temperature to 100-110DEG C, transferring ammoniation liquid into am acid precipitation kettle, processing acid precipitation via hydrochloride (or dilute sulfuric acid) at 75-100DEG C until pH is 1-2, filtering and washing to obtain tobias acid particle crystals, centrifugally processing to obtain tobias acid wet product, and drying to obtain final product whose purity is higher than 97.00-99.00% (tested by HPLC).

Owner:WUXI HUASHENG ENVIRONMENT PROTECTION TECH

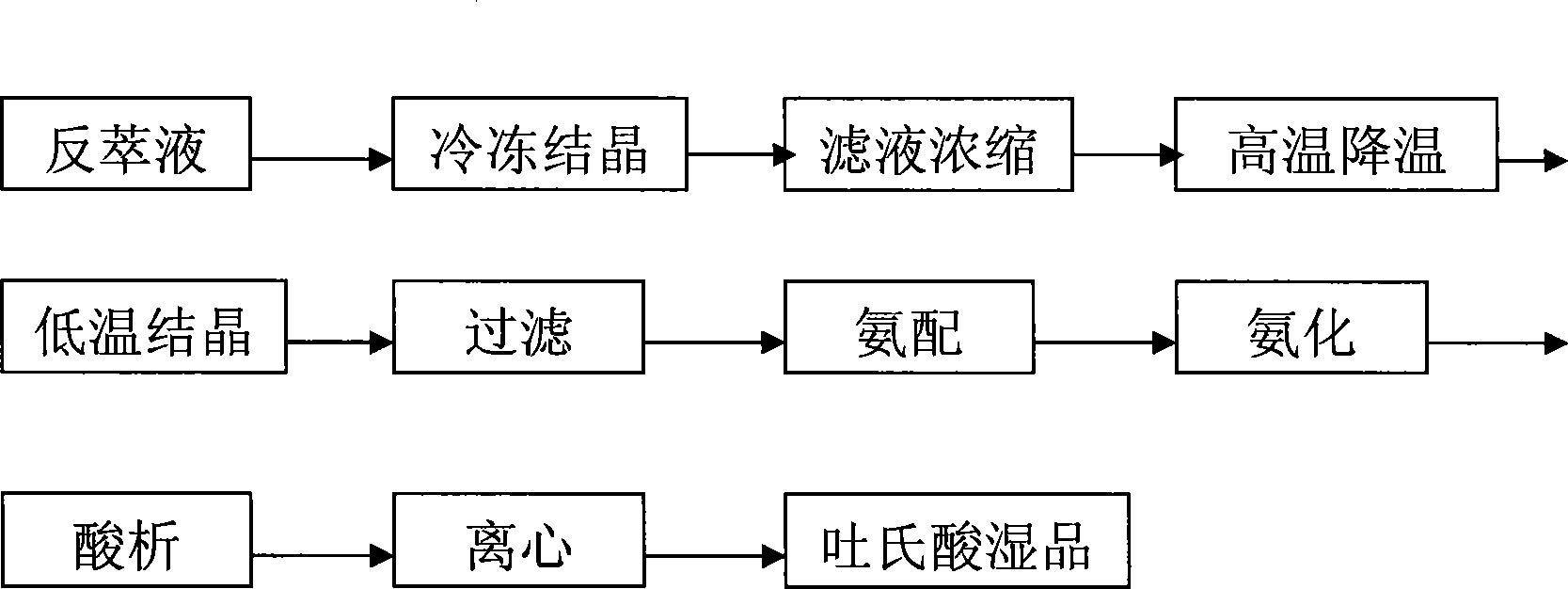

Production method of extracting active ingredient from wastewater of producing tobias acid

InactiveCN101195594AQuality assuranceReduce pollutionOrganic chemistryOrganic compound preparationTobias acidWastewater

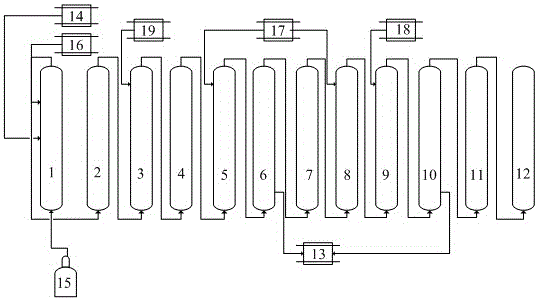

The invention discloses a method for extracting effective component from the production waste water of Tobias acid to produce Tobias acid further, which comprises processing extraction and back extraction on the waste water of Tobias acid production, freezing and desalting strip liquor to obtain denitration liquid, evaporating, concentrating, freezing and crystallizing denitration liquid, separating to obtain mixture salt, using ammoniation and acid out processes to obtain Tobias acid with purity higher than 99.0%. The inventive preparation method has simple and reliable process, high yield, and non environment pollution, which eliminates foreigner material accumulation caused by simply recovering strip liquor to avoid affecting product quality. Each cubic meter of strip liquor can produce 60-70kg Tobias acid which purity is higher than 99%, to reduce cost, improve yield, and support simple and reliable method for further advanced treatment of waste water.

Owner:TIANJIN NORMAL UNIVERSITY

Method for preparing refined tobias acid from tobias acid wastewater

ActiveCN103288690AReduce consumptionReduce ammonia nitrogen contentOrganic chemistryOrganic compound preparationTobias acidDissolution

The invention relates to a production method of refined tobias acid from a tobias acid stripping solution after performing extraction-stripping in tobias acid wastewater. The invention aims at providing a method for preparing the refined tobias acid from the tobias acid wastewater, which can reduce consumption of energy and materials and also reduces the content of ammonia nitrogen and the content of strong cancerogenic substance, namely 2-naphthylamine in the wastewater. The adopted technical scheme is as follows: the method comprises the following steps of: performing acidolysis and centrifugal separation on the striping solution obtained by performing extraction-stripping on the wastewater for producing the tobias acid, and abandoning filtrate to obtain a tobias acid stripping material; heating the tobias acid stripping material, performing alkali dissolution, and then performing hot filtration to obtain a stripping material alkaline solution; performing cooling, crystallization, secondary acidolysis and centrifugal filtration on the stripping material alkaline solution to obtain a tobias acid wet product; and beating and washing the tobias acid wet product with ethanol, and performing centrifugal filtration and drying to obtain the tobias acid with the purity of not less than 97.0%. The production method disclosed by the invention can be widely applied in the technical field of preparation of the refined tobias acid from the tobias acid wastewater.

Owner:山西翔宇化工有限公司

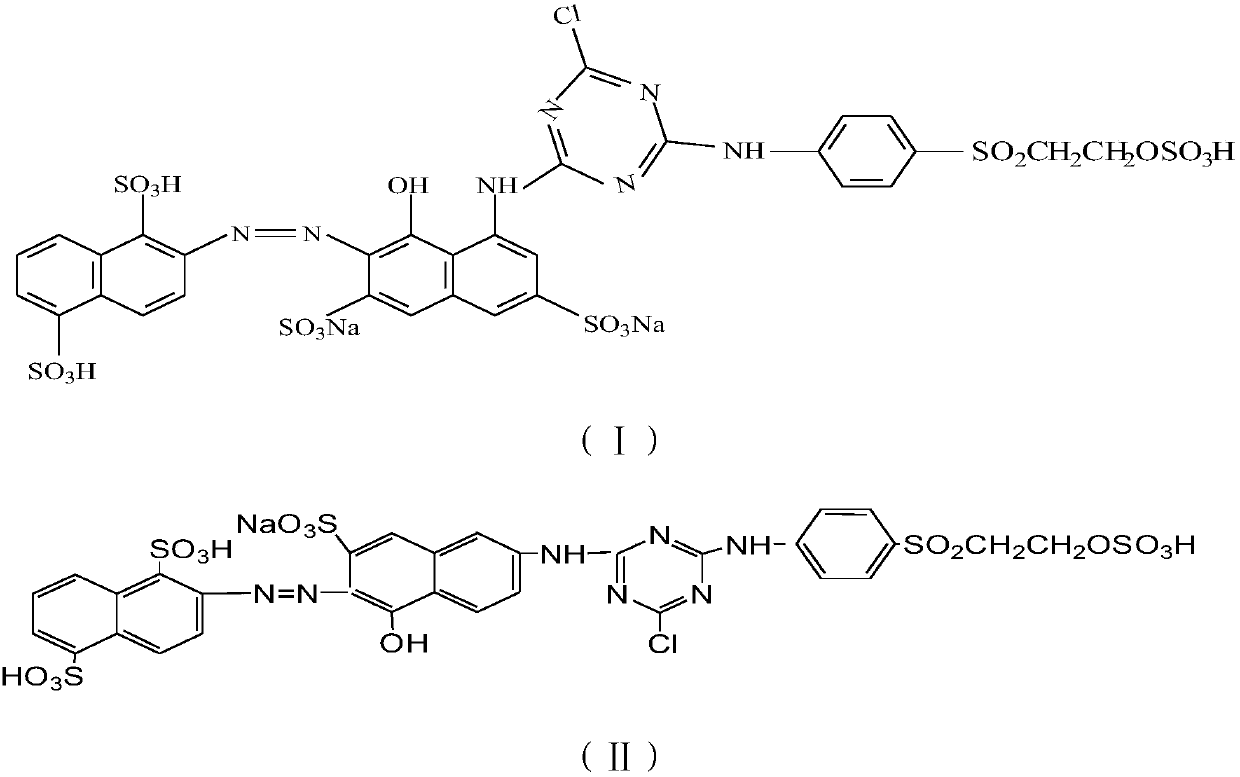

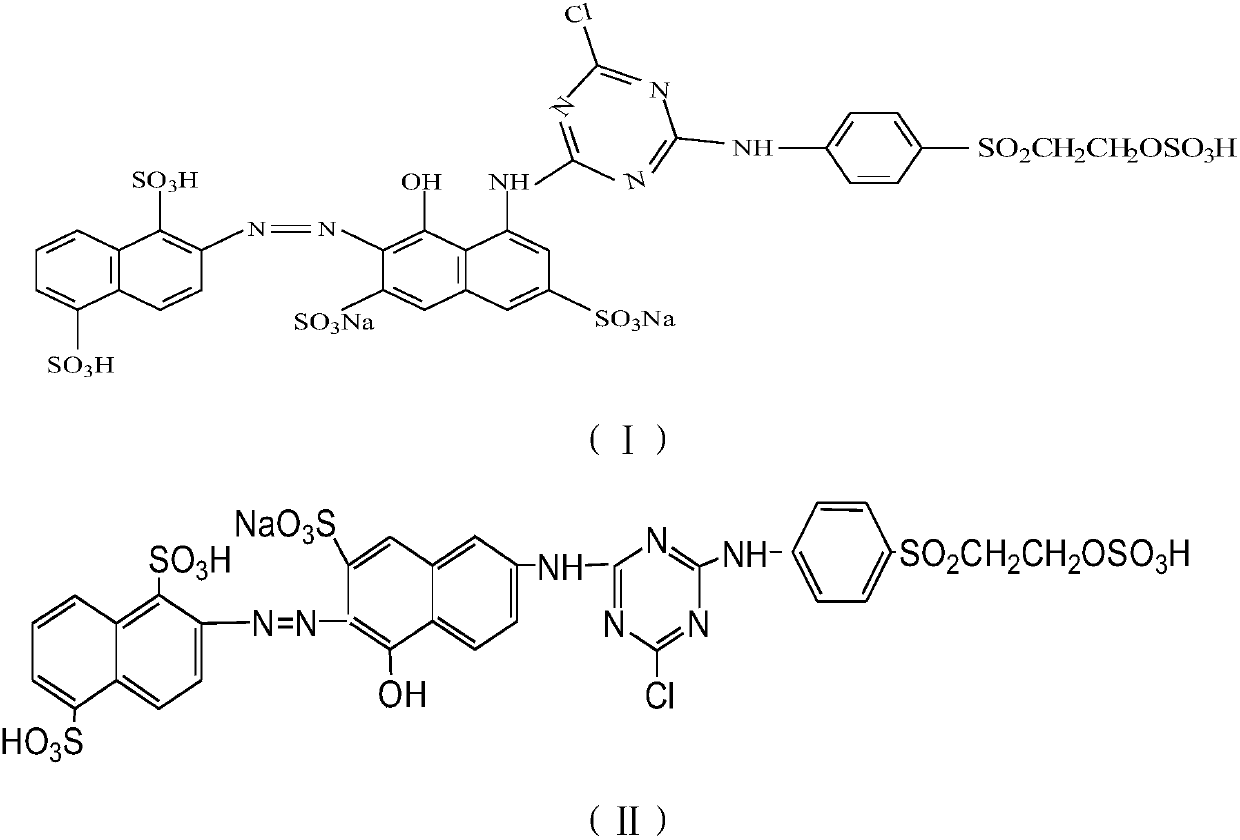

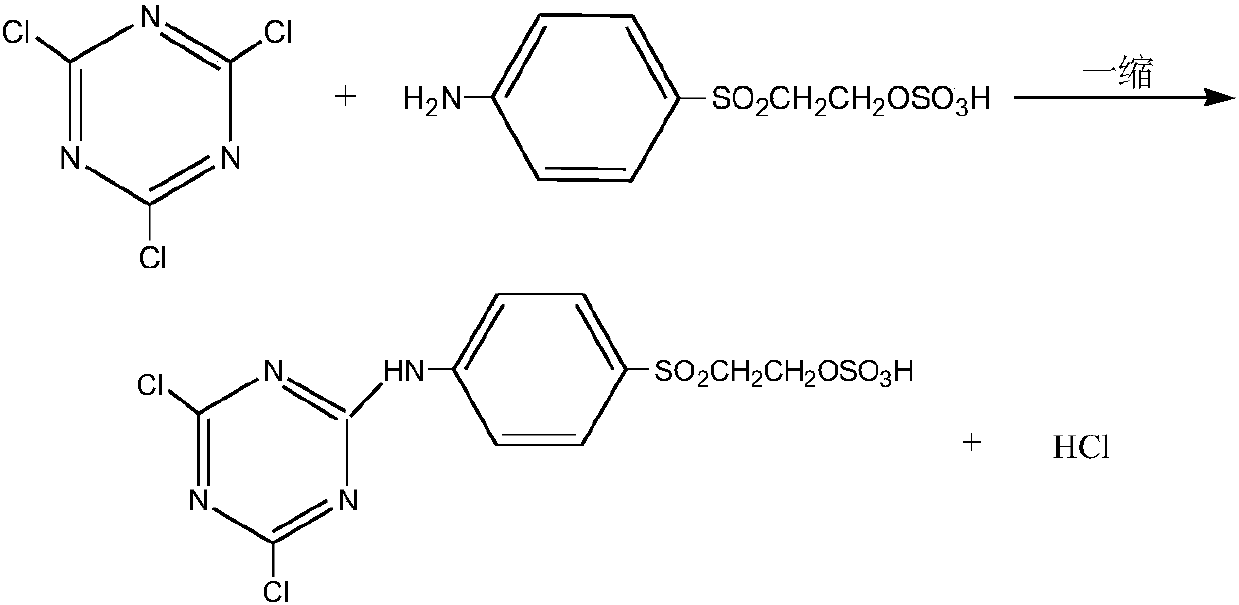

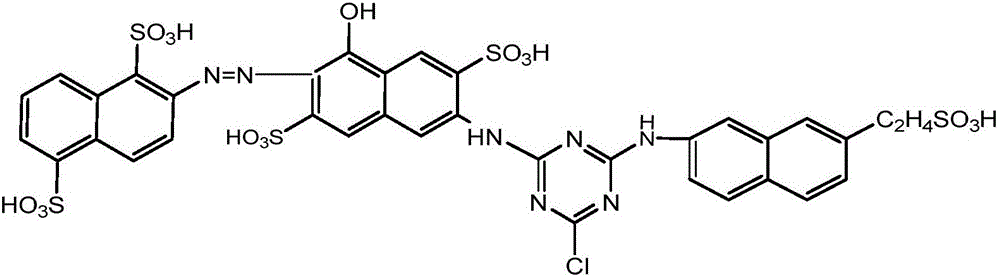

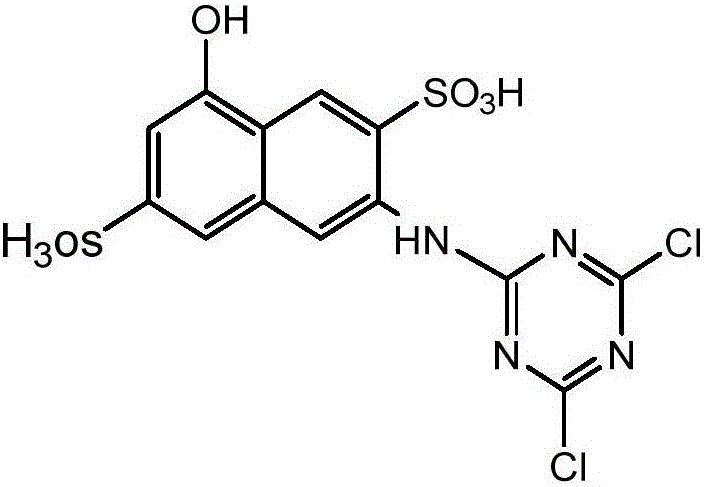

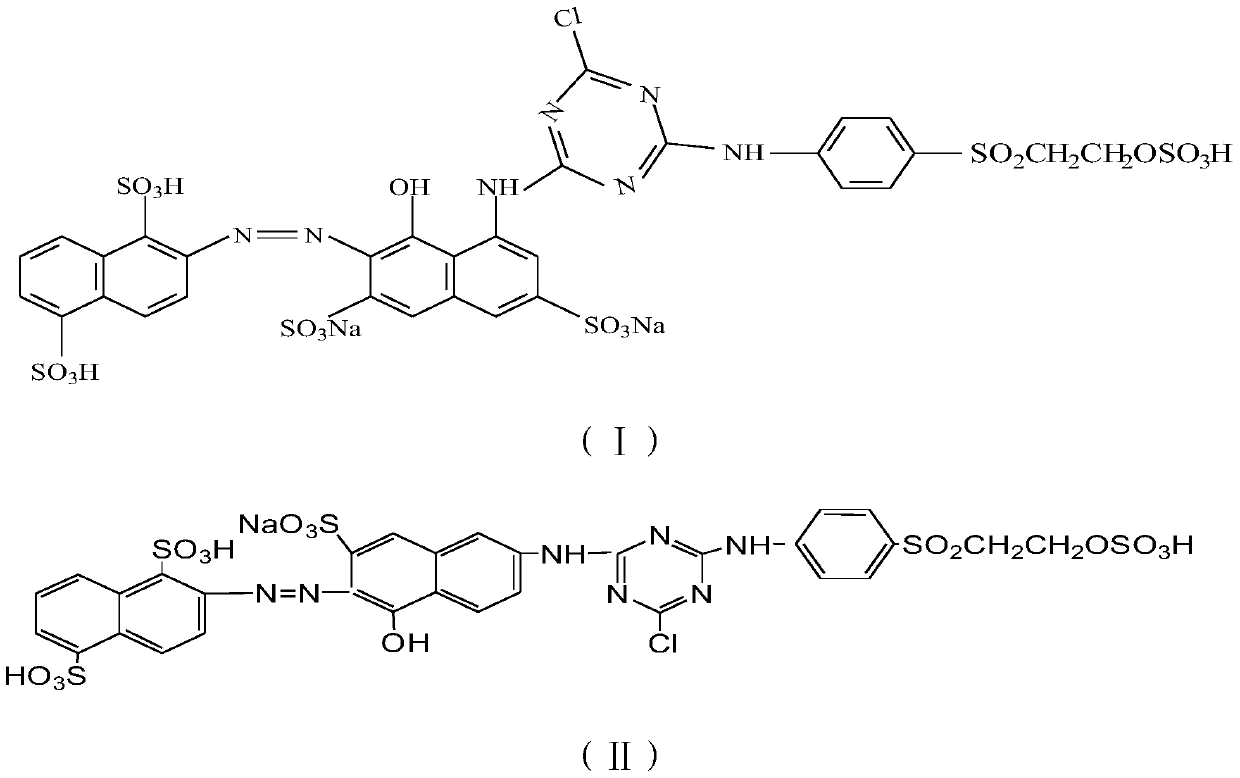

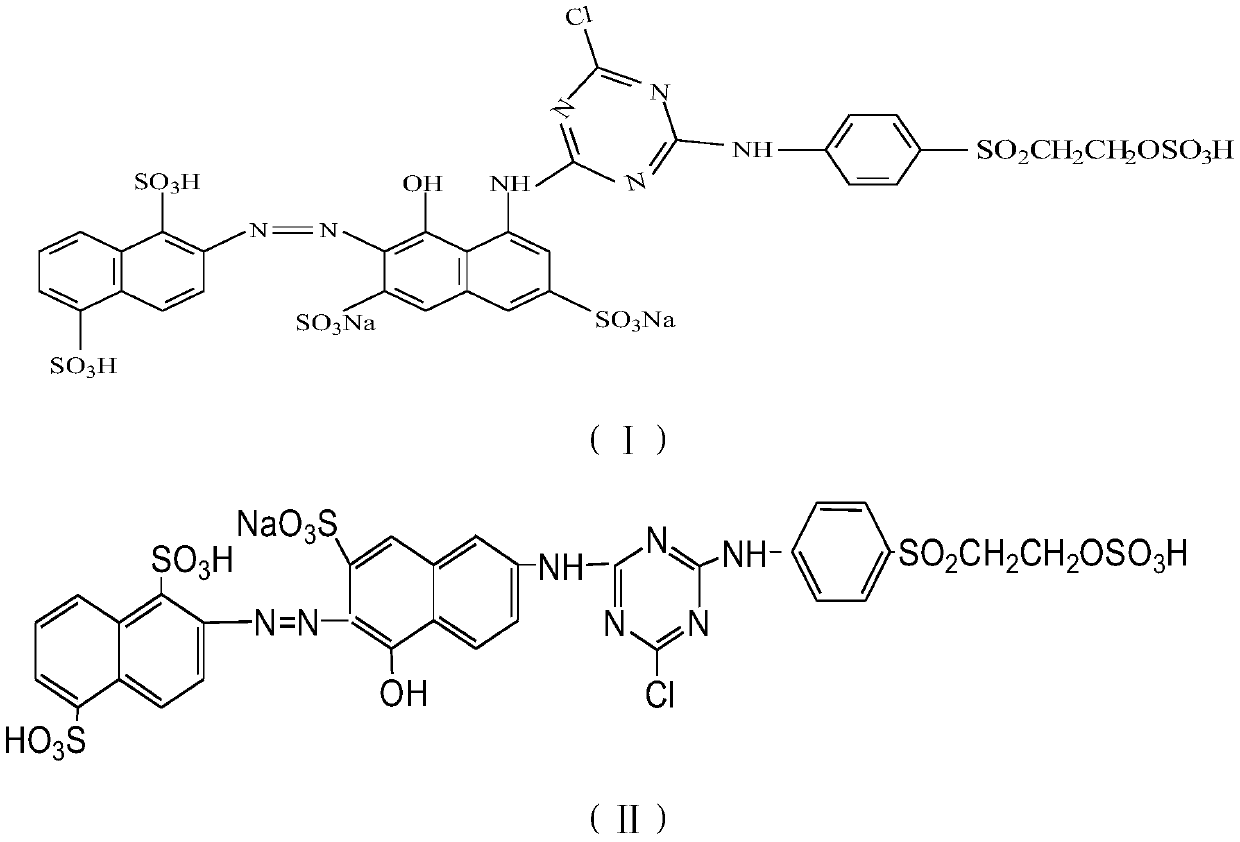

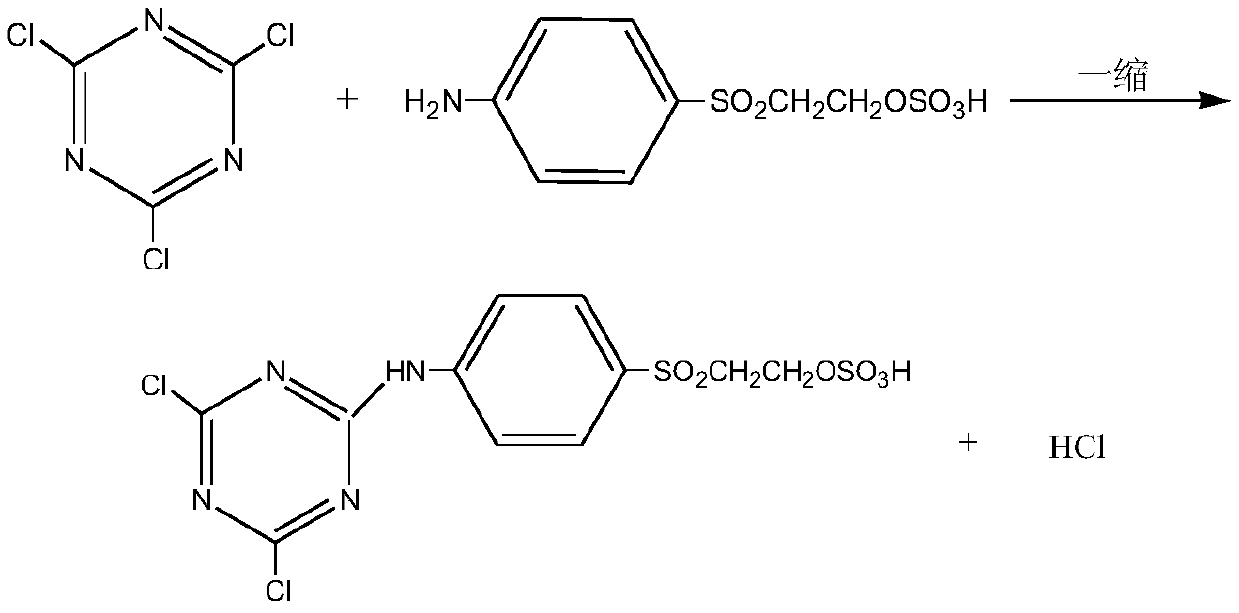

Preparation method for reaction red dye

The invention relates to a preparation method for a reaction red dye. The preparation method comprises the following steps: adding cyanuric chloride into ice water, and carrying out pulping treatmentso as to obtain a pulped solution; adding solid para-ester into the pulped solution, continuing adding a mixed alkaline solution so as to regulate alkalinity, and carrying out a condensation reactionso as to obtain a first condensate, wherein the mixed alkaline is sodium carbonate and baking soda; adding solid J acid into the first condensate, and carrying out a condensation reaction so as to obtain a second condensate; continuing adding solid H acid into the second condensate, and carrying out a condensation reaction so as to obtain a mixed second condensate, wherein the mol ratio of the solid J acid to the solid H acid is (0.65-0.68): (0.32-0.35); adding hydrochloric acid and sodium nitrite into sulfonated tobias acid, and carrying out a diazotization reaction so as to obtain sulfonatedtobias acid diazotized salt; and adding the sulfonated tobias acid diazotized salt into the mixed second condensate, carrying out a coupling reaction, and carrying out post-treatment so as to obtainthe reaction red dye. The preparation method provided by the invention is convenient and rapid, occupies few resources, has low energy consumption, and facilitates color matching.

Owner:ZHEJIANG JINGGUANG IND

Waste water treating and resourcelization method for tobias acid production

InactiveCN1775698ARealize resourcesPromote regenerationMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationTobias acid

The invention discloses a tobias acid production waste water controlling and resource recovering method, and the method regulates the pH value of the tobias acid production waste water, filters and makes main organic matters in the waste water absorbed on resin by the combination process of macroporous weakly basic resin and ultrahigh cross-linking absorption resin. The crude waste water: puce, chroma 1500-2000, iodinated tobias acid concentration 12000-15000 mg / L, tobias acid and 2, 1-acid concentration 6000-7000 mg / L, and COD 45000-5000 mg / L, and the processed waste water: chroma 10-50, iodinated tobias acid concentration < 500mg / L, tobias acid and 2, 1- acid concentration <50 mg / L, CODCr<1500mg / L, and the resins are regenerated by liquid alkali and water de-absorption, the high concentration deabsorption solution returns to amination stage of the tobias acid producing process, low concentration deabsorption solution is used indiscriminately in the next deabsoption operation, the sulphonated tobias acid is above 10 kg recovered from per cubic meter of waste water sample and the tobias acid is above 5 kg.

Owner:NANJING UNIV +1

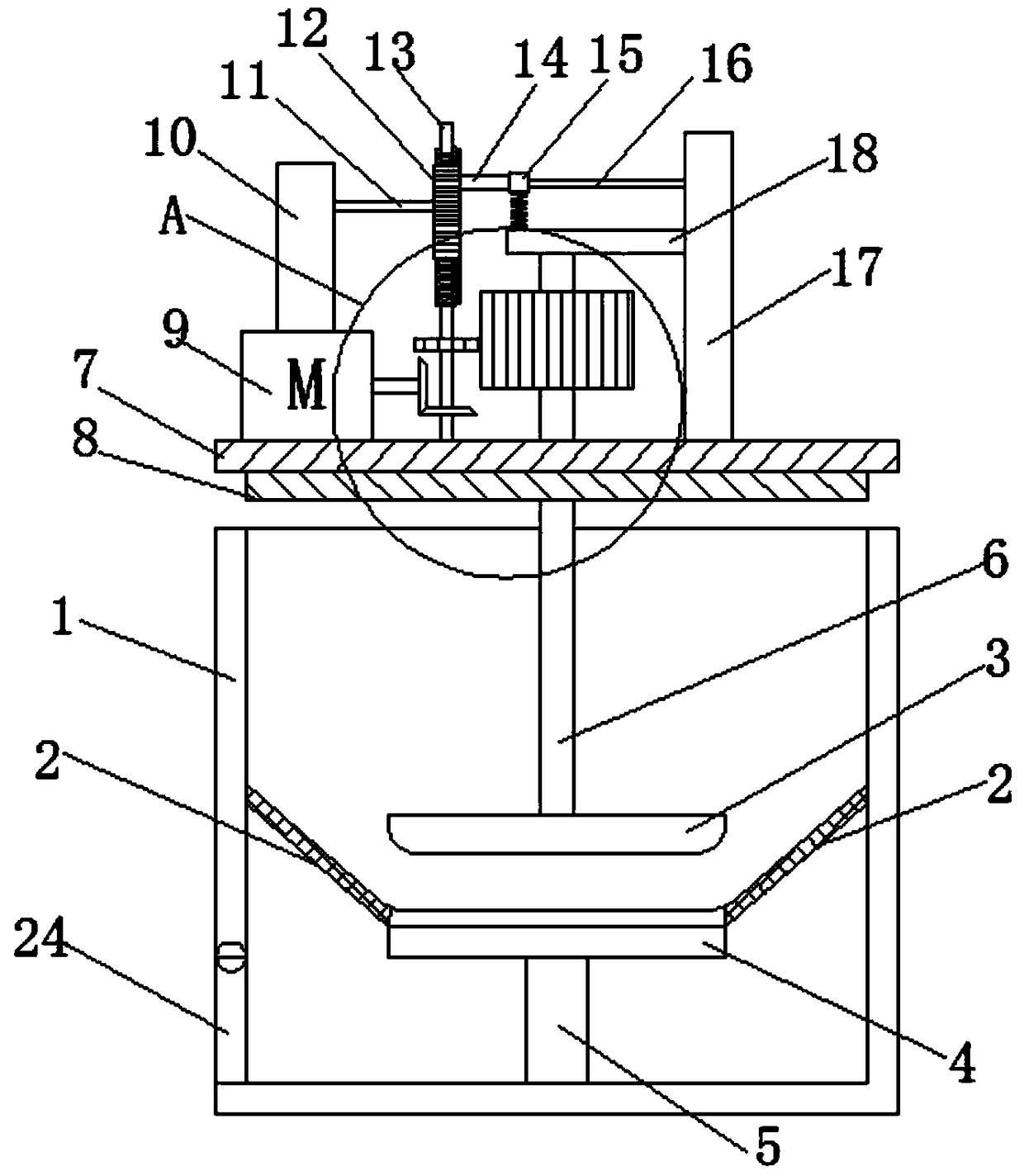

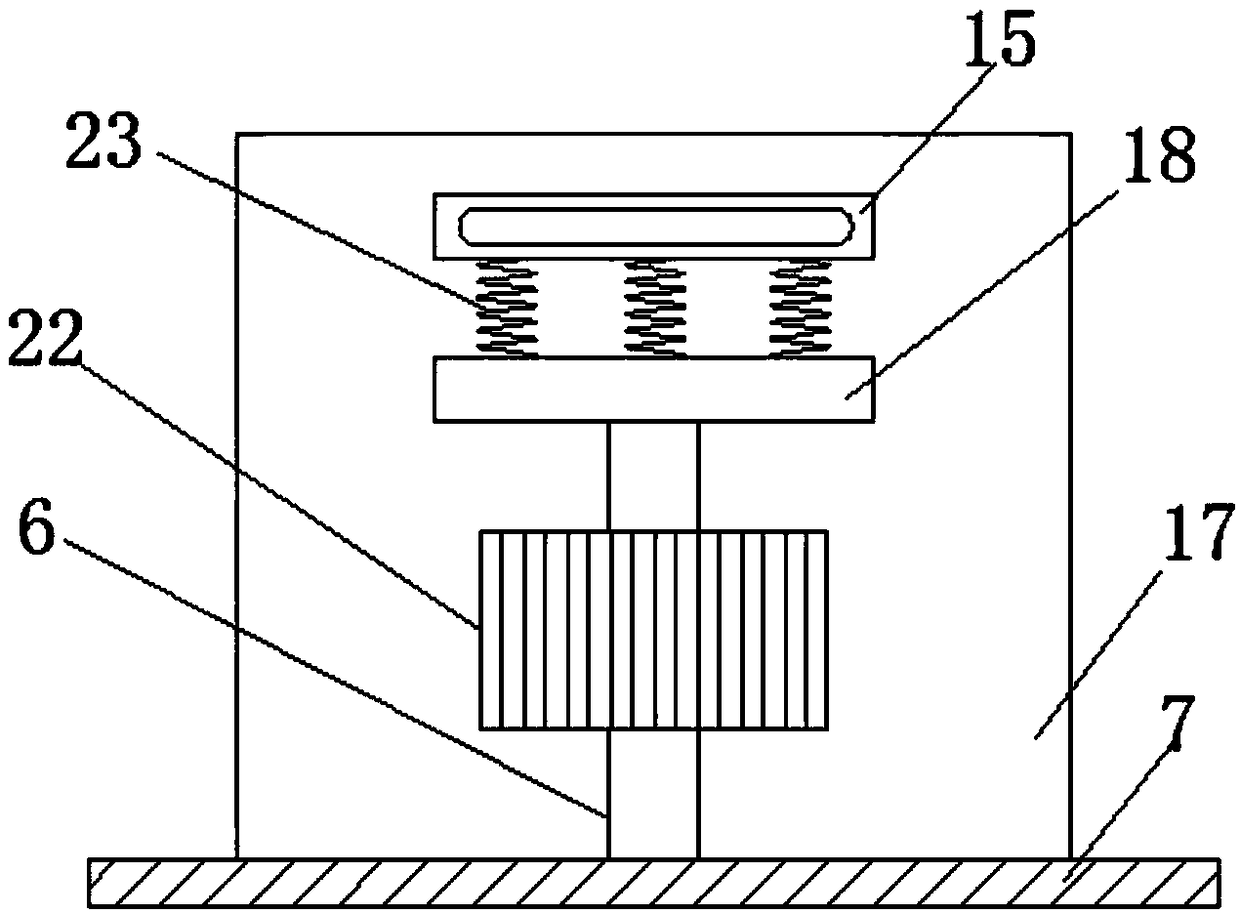

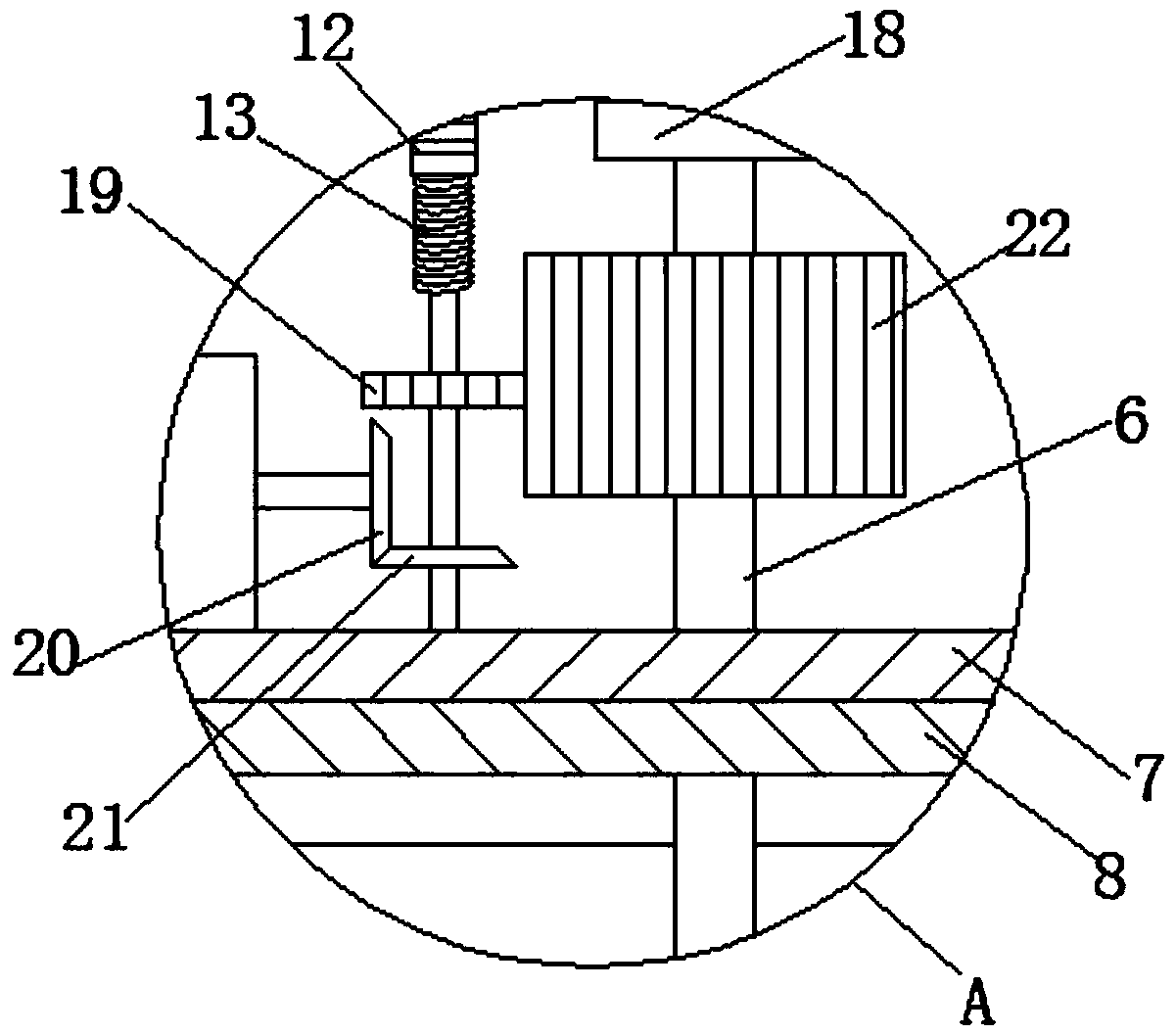

Production system for preparing sulpho tobias acid

The invention discloses a production system for preparing sulpho tobias acid, wherein the production system comprises a grinding box body; the bottom of the grinding box body is welded with a supportcolumn. In the production system, a servo motor drives a grinding disc to rotate through two engagements, and at the same time, a spring can continuously apply downward pressure to a second movable plate. Therefore, when massive sulpho tobias acid is ground into a small state by the grinding disc, the grinding disc can move downwards and performs continuous grinding, and at the same time, a cylindrical pin on a worm wheel drives a sliding plate to move up and down, so that downward pressure applied to the second movable plate is periodically changed, the grinding effect is better, and sulpho tobias acid ground into powder is also convenient to disperse all around and falls down from a filter screen. The grinding device completes the crushing process in the sulpho tobias acid production system conveniently, the working efficiency is higher than that of manual crushing, moreover, a lot of labor costs are saved, the crushed sulpho tobias acid is uniform, and the value of finished productsis greatly improved.

Owner:天津市科德化工有限公司

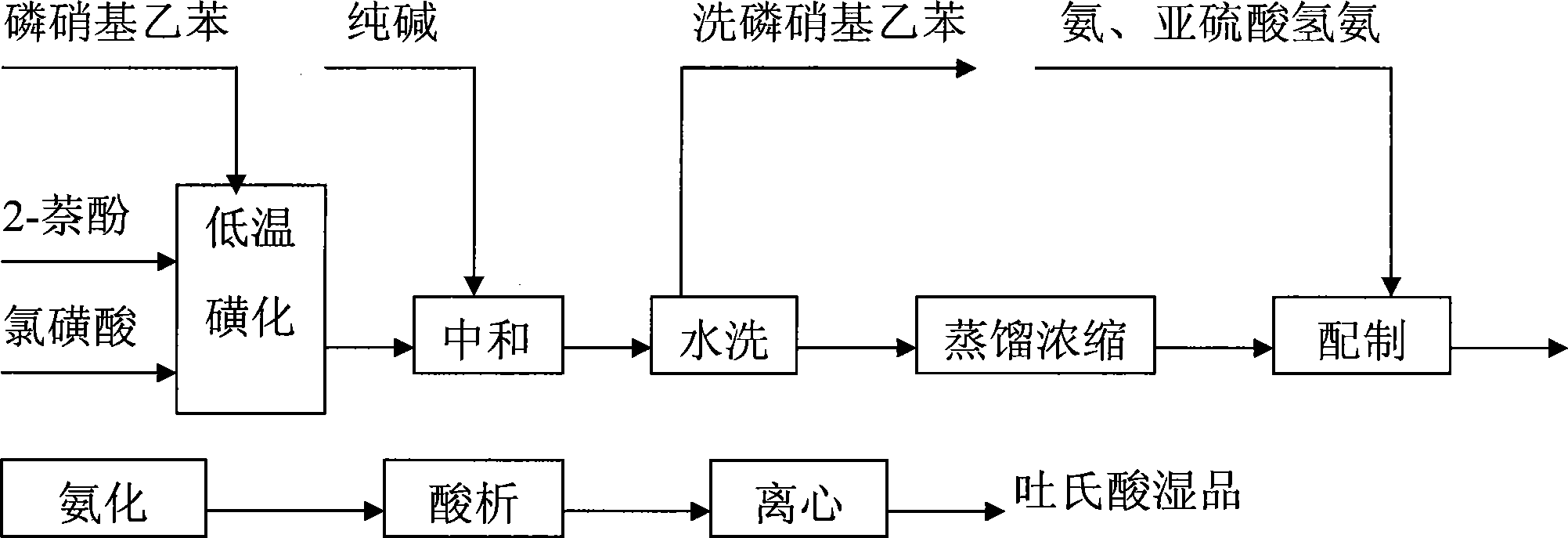

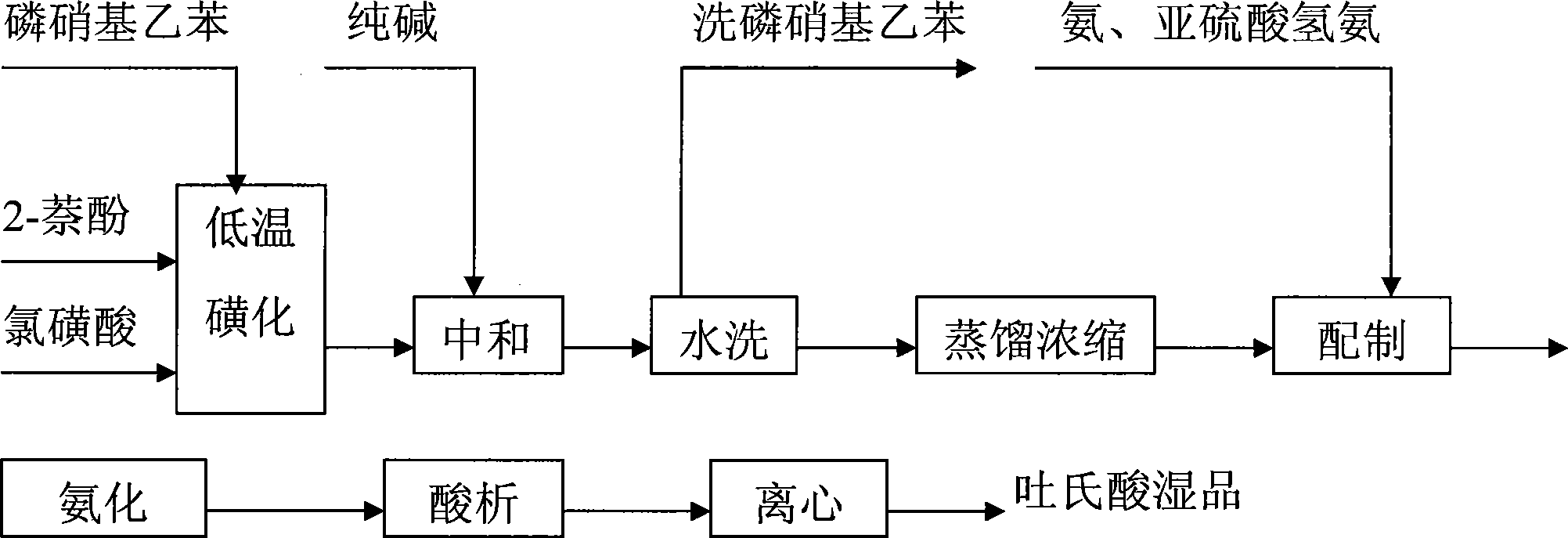

Preparation method of sodium tobias salt

The invention relates to a preparation method of sodium tobias salt, particularly relates to a preparation method of an environment-friendly sodium tobias salt product and solves the problems that tobias acid powder obtained through the prior art is large in dust pollution and difficult to be dissolved in water. The preparation method disclosed by the invention is improved based on a conventional tobias acid production process, the steps including acidification, filter pressing, drying and the like are saved after low-temperature sulfonation, neutralization reaction and high-pressure amination reaction of 2-isonaphthol in the conventional process, a high-pressure amination reaction solution is sequentially subjected to the steps including filtration, percolation, concentration and the like, and a small amount of a sterilizing agent and an anti-freezing agent are added to obtain a liquid sodium tobias salt product which can be stably stored for more than 6 months; or a small amount of a dispersant is added, and then a particle-like sodium tobias salt product with extremely-good dispersity can be obtained through a pressure spray drying process.

Owner:山西翔宇化工有限公司

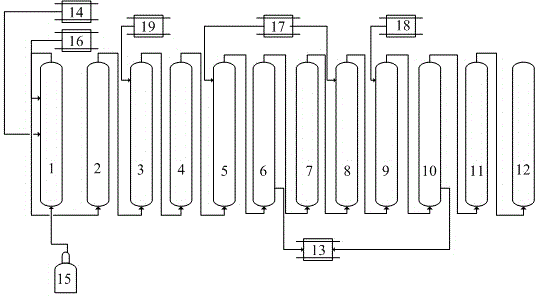

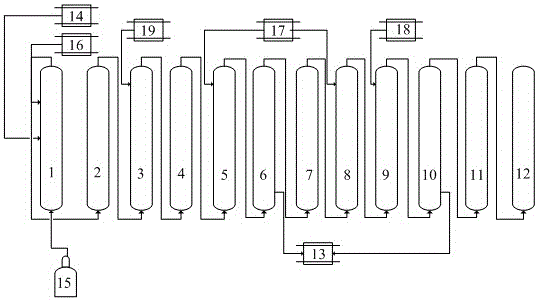

System for industrial preparation of 2-amino-5-naphtol7-sulfoacid

ActiveCN104945290AIncrease profitProcess conditions Environmental protection and energy savingSulfonic acids salts preparationSulfur-trioxide/sulfuric-acidFiltrationLiquid storage tank

The invention discloses a system for industrial preparation of 2-amino-5-naphtol7-sulfoacid. The system comprises a first synthesis reaction still, a second synthesis reaction still, a hydrolyzation reaction still, a regulation reaction still, a dissolution reaction still, a suction filtration reaction still, a concentration reaction still, a third synthesis reaction still, an acidification reaction still, a centrifugation reaction still, a drying reaction still, a finished product storage tank, a sewage treatment system, a Tobias acid liquid storage tank, a sulfur trioxide gas storage bottle, a concentrated sulfuric acid liquid storage tank, a sodium hydroxide solid storage tank, a hydrochloric acid liquid storage tank and a pure water storage pool. The 2-amino-5-naphtol7-sulfoacid prepared through the system is high in purity, the purity is over 92.8%, the water content is lower than 1%, the crystallizing rate is smaller than 0.5%, and free acid is smaller than 5%.

Owner:甘肃永鸿染化有限公司

Production method of extracting active ingredient from wastewater of producing tobias acid

InactiveCN101195594BQuality assuranceReduce pollutionOrganic chemistryOrganic compound preparationTobias acidWastewater

The present invention discloses a method for extracting effective component from the production waste water of Tobias acid to produce Tobias acid further, which comprises processing extraction and back extraction on the waste water of Tobias acid production, freezing and desalting strip liquor to obtain denitration liquid, evaporating, concentrating, freezing and crystallizing denitration liquid, separating to obtain mixture salt, using ammoniation and acid out processes to obtain Tobias acid with purity higher than 99.0%. The inventive preparation method has simple and reliable process, high yield, and non environment pollution, which eliminates foreigner material accumulation caused by simply recovering strip liquor to avoid affecting product quality. Each cubic meter of strip liquor can produce 60-70kg Tobias acid which purity is higher than 99%, to reduce cost, improve yield, and support simple and reliable method for further advanced treatment of waste water.

Owner:TIANJIN NORMAL UNIVERSITY

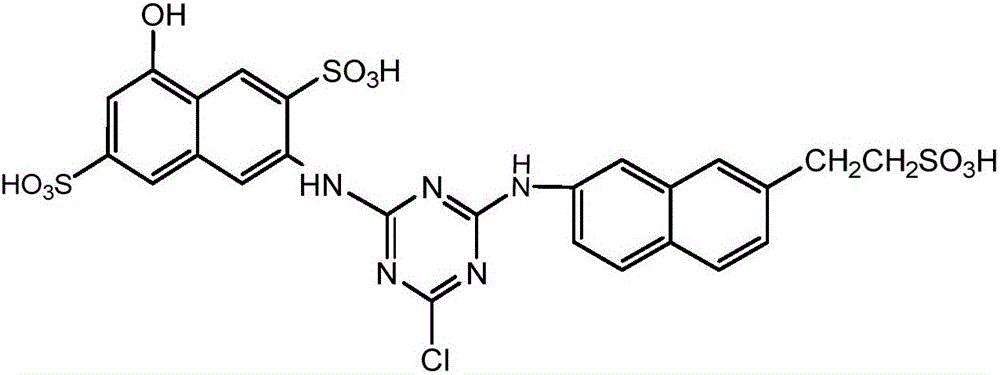

Synthesis method of active orange dye

The invention relates to a synthesis method of an active orange dye. The method comprises the following steps of (1) adding ice and a dispersing agent to cyanuric chloride, pulping to form cyanuric chloride slurry, dropwise adding a para-ester aqueous solution to the cyanuric chloride slurry and carrying out primary condensation reaction to obtain primarily concentrated liquid; (2) adding a sulfonated J acid to the primarily concentrated liquid obtained in the step (1), carrying out secondary condensation reaction to obtain a secondarily concentrated liquid; (3) pulping a sulfonated tobias acid, adding sodium nitrite and hydrochloric acid for diazo-reaction to obtain a diazo liquid; and (4) adding the diazo liquid obtained in the step (3) to the secondarily concentrated liquid obtained in the step (2) for coupling reaction, maintaining the pH value between 6.3 and 6.8 in the coupling process, carrying out spray drying after complete reaction to obtain the active orange dye. The synthesis method is simple in operation procedure, and the synthesized product dye is vivid in color light and high in solubility.

Owner:ZHEJIANG JINGGUANG IND

Device system for purifying tobias acid by utilizing tobias acid waste liquid

PendingCN109810028AWell mixedPrevent influence experimentsOrganic chemistryOrganic compound preparationLiquid wasteTobias acid

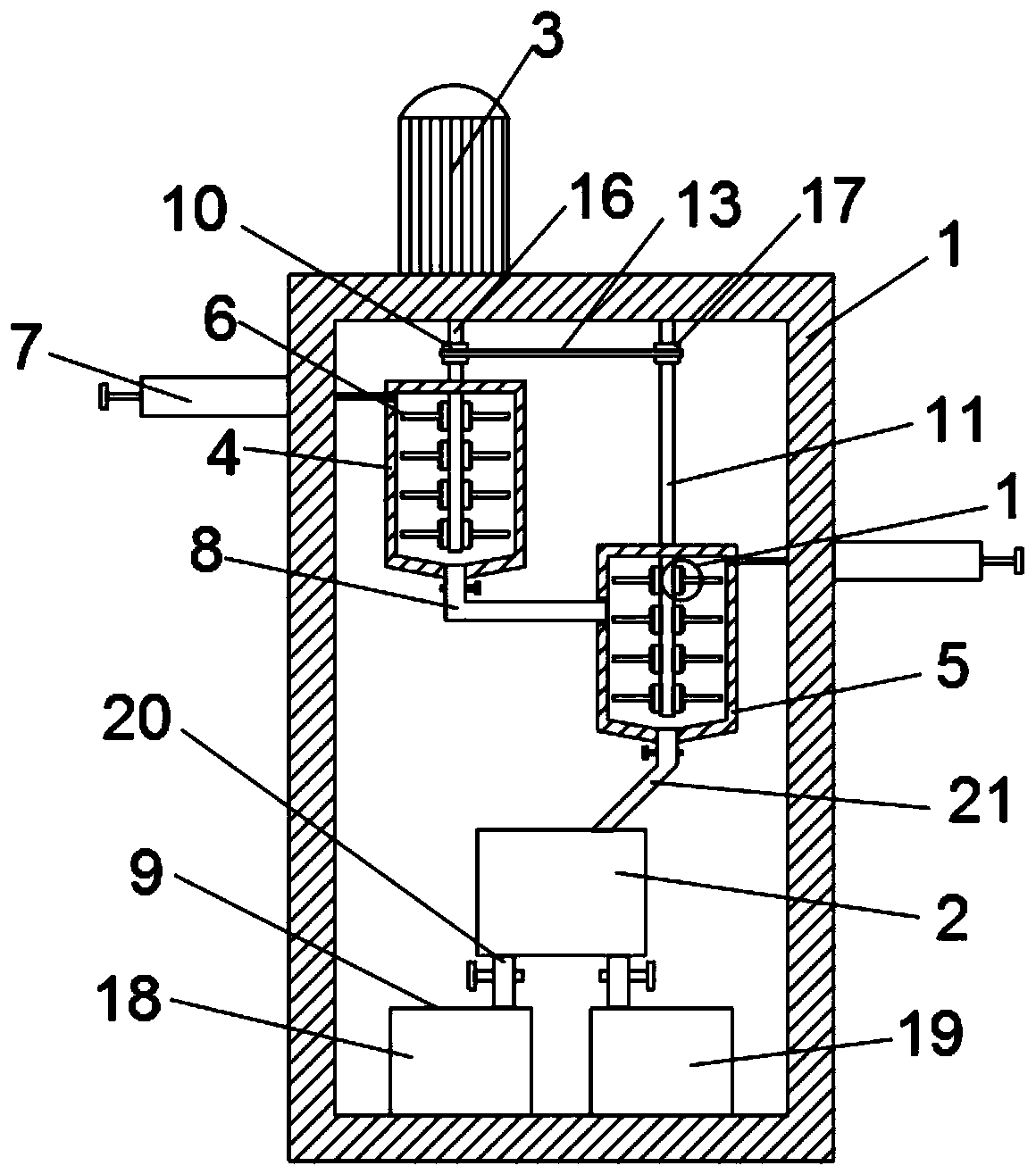

The invention discloses a device system for purifying tobias acid by utilizing tobias acid waste liquid. The device system comprises a shell body and a separation device body, wherein the upper end ofthe shell body is fixedly connected with a motor; a first extraction box and a second extraction box are fixedly connected into the shell body; a mixing mechanism is arranged at an output end of themotor; injection pipes are arranged on left and right side walls of the shell body in a manner of penetrating; output ends of the two injection pipes are communicated with the first extraction box andthe second extraction box respectively; lower ends of the first extraction box and the second extraction box are fixedly connected with output pipes; the separation device body is fixedly connected into the shell body; the two output pipes are communicated with the separation device body respectively; a collection mechanism is arranged at the lower end of the separation device body. According tothe device system disclosed by the invention, the mixing mechanism is arranged and can be used for sufficiently mixing the waste liquid and an extracting agent; a stirring blade is detachable and canbe detached and cleaned and an experiment of the next time is not influenced; a collection mechanism is arranged, can be used for collecting the tobias acid and also can be used for collecting the waste liquid, and the environment pollution is prevented.

Owner:天津市科德化工有限公司

Method for extracting and recovering tobias acid from tobias acid wastewater

ActiveCN107602430AImproving the Efficiency of Recovering Tuburic AcidShorten the timeOrganic chemistryOrganic compound preparationChemical oxygen demandTobias acid

The invention relates to a method for extracting and recovering tobias acid from tobias acid wastewater. The method comprises the following steps: mixing tobias acid wastewater and a first extractionagent, and layering to obtain a first raffinate phase and first extracted water; mixing the first extracted water and a second extraction agent, and layering to obtain a second raffinate phase and second extracted water; merging the first raffinate phase and the second raffinate phase, adding liquid caustic soda to be mixed, and layering to obtain strip liquor and an extraction agent; and performing centrifugal separation on the strip liquor so as to obtain a solid material, and evaporating the solid material to dryness, thereby obtaining the tobias acid. According to the method disclosed by the invention, the recovery efficiency is improved, the time is saved, and the cost is reduced. Meanwhile, the COD (Chemical Oxygen Demand) of the strip liquor obtained by extraction-back extraction isdecreased from 40000mg / l to 4000mg / l, the COD removal rate reaches 90%, the acidity is decreased from 40-60mg / l to 20mg / l or less, the cost during neutralization is reduced, and the tobias acid reaching the standard can be directly obtained.

Owner:XIANGSHUI HENRYDA TECH CHEM

Preparation method of pigment used for water-based ink

ActiveCN102311658AGood viscosity stabilityNo change in viscosityMonoazo dyesInksWater based2-Naphthol

The invention discloses a preparation method of a pigment used for water-based ink, which comprises the following steps: stirring 50-200 parts of water and 22 parts of sodium hydroxide, adding 22-24 parts of tobias acid and 0.1-2 parts of 2, 6 acid, dissolving, filtering, adding 28.4 parts of hydrochloric acid at the temperature of -3 to 2 DEG C, stirring, adding 30.4 parts of sodium nitrite solution, stirring at the temperature of 0-5 DEG C, adding 56 parts of calcium chloride solution, and stirring to obtain a solution I; stirring 200-720 parts of water and 24.5 parts of sodium hydroxide, adding 16 parts of 2-naphthol to dissolve at the temperature of 20-60 DEG C and filter, and adding 0.1-5.6 parts of rosin solution and 0.1-4 parts of turkey red oil solution into a filtrate at the temperature of 20-60 DEG C to obtain a solution II; adding the solution II into the solution I at the temperature of 0-5 DEG C to couple for 20 minutes, stirring for 30-60 minutes at the temperature of 10-15 DEG C, raising the temperature to 65-90 DEG C to transform completely, stirring for 10-30 minutes, filtering by pressing, washing filter cakes by water, and removing moisture in the filter cakes to obtain the pigment used for water-based ink. The viscosity stability of ink prepared from the pigment used for water-based ink disclosed by the invention is high, and after the treatment of 48 hours at the temperature of 50 DEG C, the viscosity is still basically unchanged.

Owner:LONGKOU UNION CHEM

Method for preparing refined tobias acid from tobias acid wastewater

ActiveCN103288690BReduce consumptionReduce ammonia nitrogen contentOrganic chemistryOrganic compound preparationTobias acidDissolution

The invention relates to a production method of refined tobias acid from a tobias acid stripping solution after performing extraction-stripping in tobias acid wastewater. The invention aims at providing a method for preparing the refined tobias acid from the tobias acid wastewater, which can reduce consumption of energy and materials and also reduces the content of ammonia nitrogen and the content of strong cancerogenic substance, namely 2-naphthylamine in the wastewater. The adopted technical scheme is as follows: the method comprises the following steps of: performing acidolysis and centrifugal separation on the striping solution obtained by performing extraction-stripping on the wastewater for producing the tobias acid, and abandoning filtrate to obtain a tobias acid stripping material; heating the tobias acid stripping material, performing alkali dissolution, and then performing hot filtration to obtain a stripping material alkaline solution; performing cooling, crystallization, secondary acidolysis and centrifugal filtration on the stripping material alkaline solution to obtain a tobias acid wet product; and beating and washing the tobias acid wet product with ethanol, and performing centrifugal filtration and drying to obtain the tobias acid with the purity of not less than 97.0%. The production method disclosed by the invention can be widely applied in the technical field of preparation of the refined tobias acid from the tobias acid wastewater.

Owner:山西翔宇化工有限公司

Sulfonation reaction kettle for sulfonated tobias acid

PendingCN109876758AFully contactedHigh purityChemical/physical/physico-chemical stationary reactorsSulfonic acid preparationTobias acidRaw material

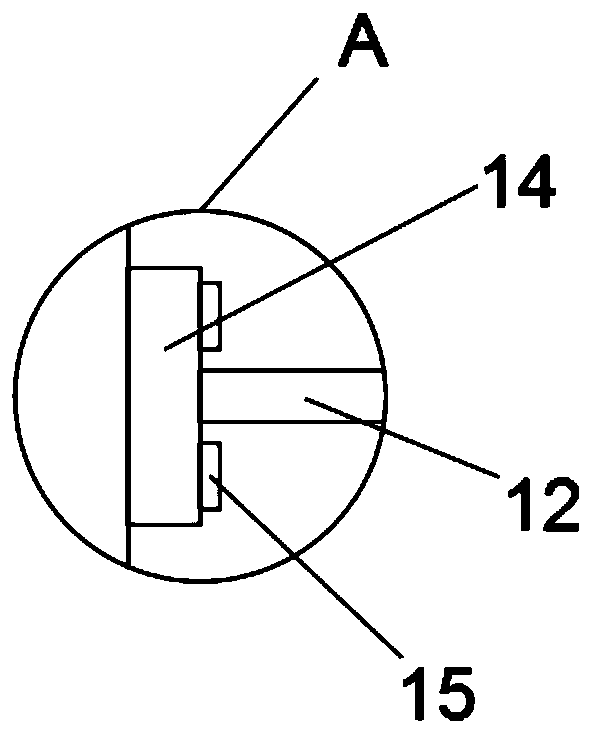

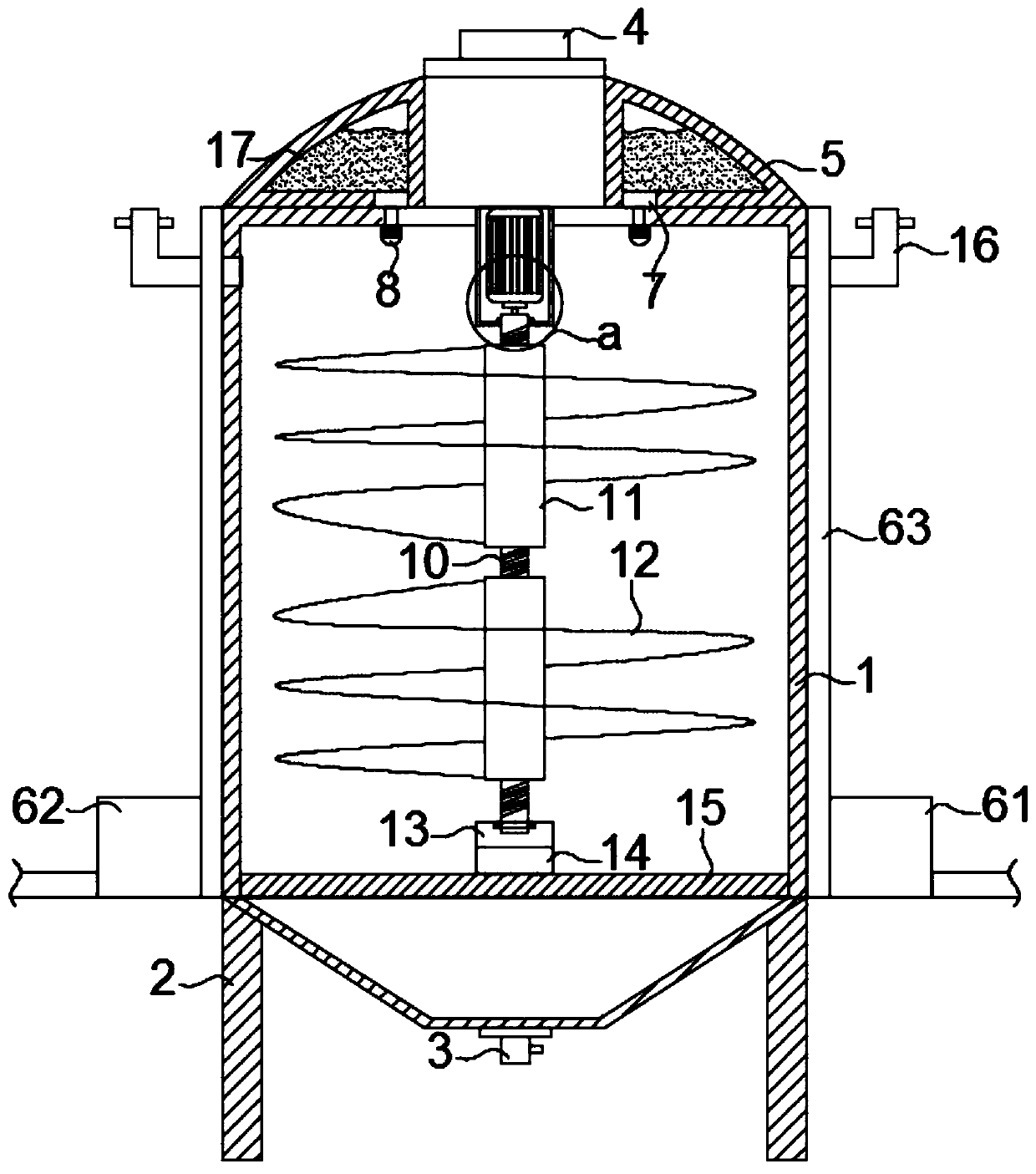

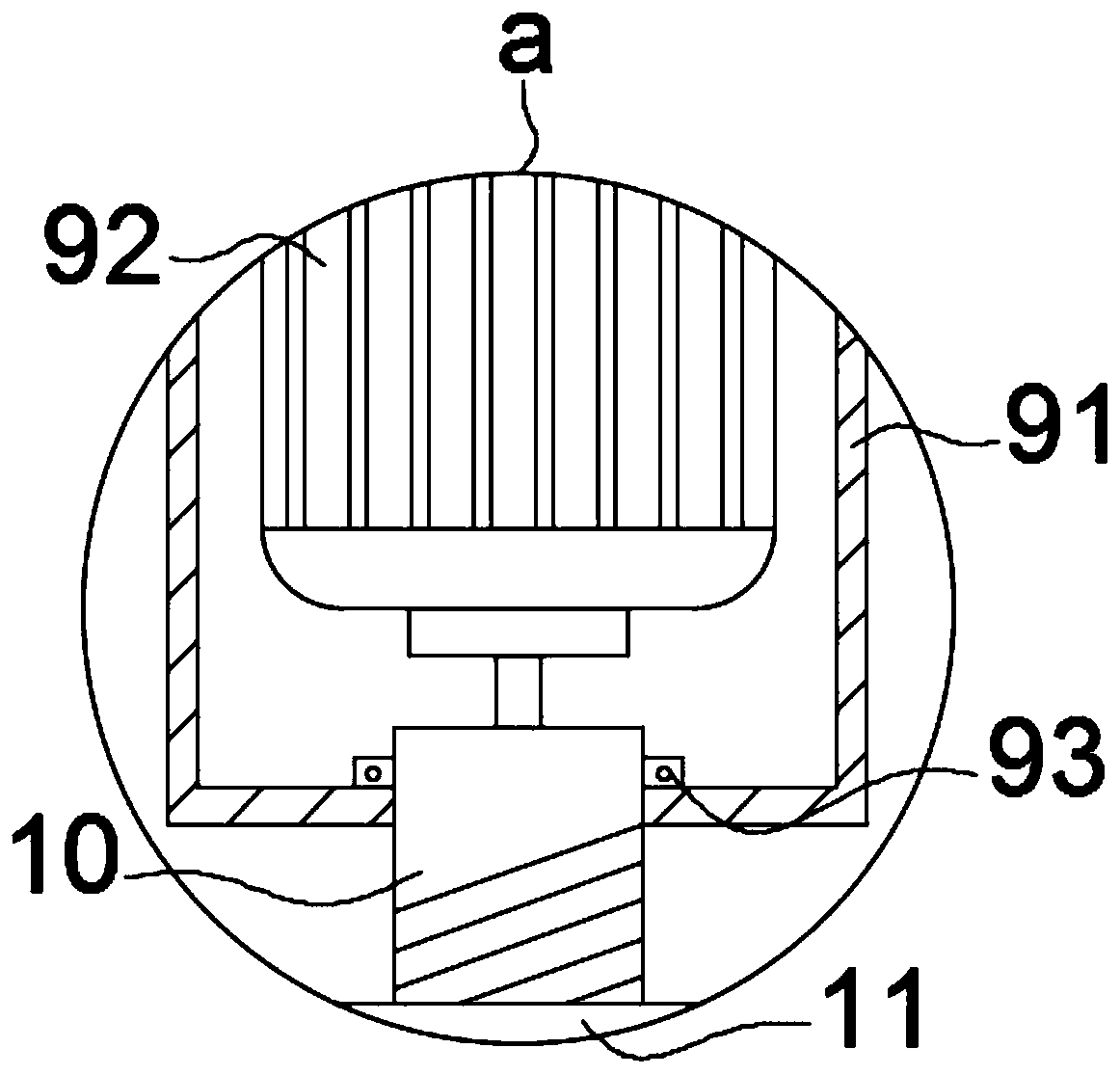

The invention discloses a sulfonation reaction kettle for sulfonated tobias acid. The sulfonation reaction kettle comprises a kettle body; the kettle body is fixedly connected with a bracket; a feeding port and an acid liquor box are arranged on the upper side of the kettle body; a discharging valve is arranged on the lower side of the kettle body; a temperature regulator and a mother liquor headare arranged on the outer surface of the kettle body; a screw driven by a driving component is arranged in the kettle body; the screw is meshed with a sliding drum fixedly connected with a stirring blade; the screw is fixedly connected with a support pillar through a bearing; the support pillar is connected with the kettle body through a connecting plate; a temperature sensor is arranged on the lower part of the support pillar. The acid liquor box filled with acid liquor is arranged on the upper end of the reaction kettle, the acid liquor is added into the reaction kettle by an atomizing sprayer through a switch valve, and then the screw is driven to rotate by a motor and moves up and down together with the meshed sliding drum with the stirring blade, so that physicochemically treated acidliquor is in full contact with raw materials and the sulfonated tobias acid in ultrahigh purity can be prepared.

Owner:天津市科德化工有限公司

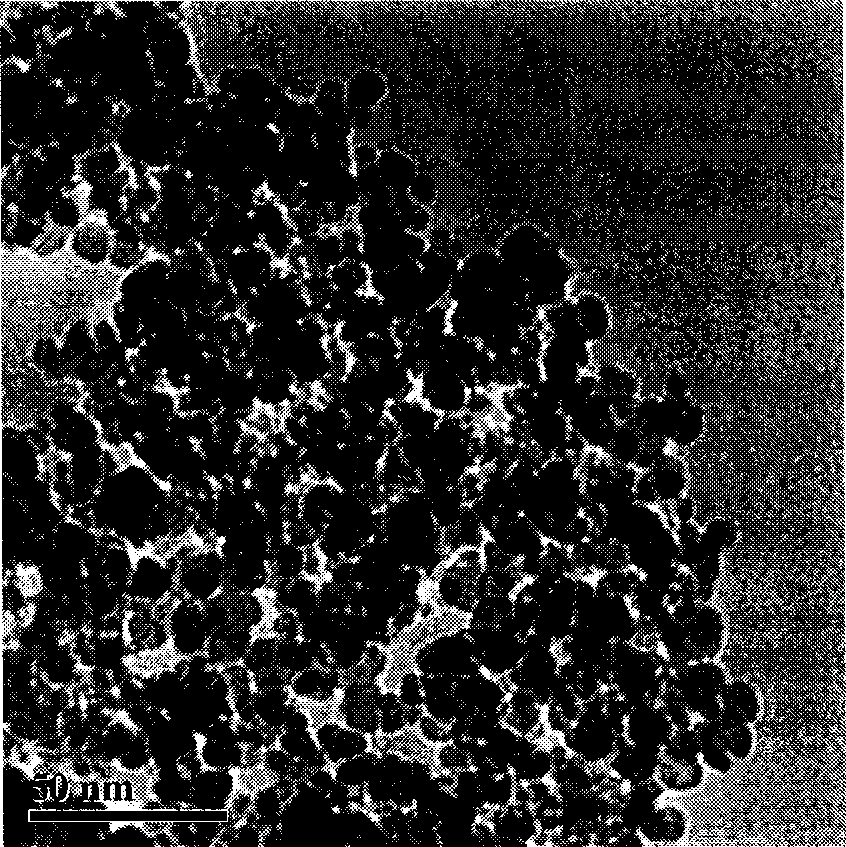

Method for preparing polar solvent soluble nano ferriferrous oxide granule

InactiveCN100355661CGood dispersionThe reaction process is simpleFerroso-ferric oxidesHigh concentrationSuperparamagnetism

The invention relates to a controlling and resource recovering method for waste water in tobias acid production, adjusting the pH of the waste water and filtering, and making main organic matters in the waste water absorbed on resins by macroporous weakly basic resin and super-high cross-linking absorbing resin combination. And before processing, the waste water is puce, chroma of the waste water is 45000-5000mg / L, sulphonated tobias acid concentration of the waste water is 12000-15000mg / L, tobias acid and 2, 1-acid concentration of the e waste water is 6000-7000mg / L, COD concentration of the waste water is 45000-50000mg / L, and after processing, the chroma is 10-50, sulphonated tobias acid concentration <500mg / L, the TuShi acid and 2, 1-acid concentration<50mg / L, and CODcr<1500mg / L. And the resins regenerate by de-absorption of liquid alkali and water. High concentration de-absorbing liquor returns to the aminating operation segment in the tobias acid producing process and low concentration de-absorbing liquor is used in the next de-absorbing operation.

Owner:SHANGHAI JIAOTONG UNIV

Lithol red preparing method

The invention provides a lithol red preparing method and relates to the technical field of pigments. The lithol red preparing method comprises the following steps of (1) preparing a coupling fluid bymixing and dissolving, by weight part, 3-5.6 parts of liquid alkali, 3-5 parts of ethyl naphthol and 0.6-1.5 parts of anionic surfactant; (2) preparing a diazonium solution by uniformly mixing, by weight part, 3-4.5 parts of liquid alkali, 3-4 parts of tobias acid, 3-4 parts of sulfonated tobias acid and 2-4 parts of cold distributing acid and then adding in 0.6-3 parts of hydrochloric acid and 1.5-2.8 parts of sodium nitrite for diazo reaction; (3) mixing, by weight part, 2-4 parts of liquid alkali and 2-3 parts of rosin to obtain a rosin solution; (4), mixing the coupling fluid and the diazonium solution for coupling reaction, then adding in the rosin solution and saturated barium chloride solution, adjusting the pH to 7.5-8.0 and adding in aluminum chloride to obtain lithol red. The prepared lithol red can avoid flocculation in a system when applied to ink and paint, and is free from separation, uniform in color darkness, fined in pigment particles and small in grain size.

Owner:宣城英特颜料有限公司

A kind of preparation method of torrentic acid sodium salt

The invention relates to a preparation method of sodium tobias salt, particularly relates to a preparation method of an environment-friendly sodium tobias salt product and solves the problems that tobias acid powder obtained through the prior art is large in dust pollution and difficult to be dissolved in water. The preparation method disclosed by the invention is improved based on a conventional tobias acid production process, the steps including acidification, filter pressing, drying and the like are saved after low-temperature sulfonation, neutralization reaction and high-pressure amination reaction of 2-isonaphthol in the conventional process, a high-pressure amination reaction solution is sequentially subjected to the steps including filtration, percolation, concentration and the like, and a small amount of a sterilizing agent and an anti-freezing agent are added to obtain a liquid sodium tobias salt product which can be stably stored for more than 6 months; or a small amount of a dispersant is added, and then a particle-like sodium tobias salt product with extremely-good dispersity can be obtained through a pressure spray drying process.

Owner:山西翔宇化工有限公司

A kind of preparation method of reactive scarlet dye

The invention relates to a preparation method for a reaction red dye. The preparation method comprises the following steps: adding cyanuric chloride into ice water, and carrying out pulping treatmentso as to obtain a pulped solution; adding solid para-ester into the pulped solution, continuing adding a mixed alkaline solution so as to regulate alkalinity, and carrying out a condensation reactionso as to obtain a first condensate, wherein the mixed alkaline is sodium carbonate and baking soda; adding solid J acid into the first condensate, and carrying out a condensation reaction so as to obtain a second condensate; continuing adding solid H acid into the second condensate, and carrying out a condensation reaction so as to obtain a mixed second condensate, wherein the mol ratio of the solid J acid to the solid H acid is (0.65-0.68): (0.32-0.35); adding hydrochloric acid and sodium nitrite into sulfonated tobias acid, and carrying out a diazotization reaction so as to obtain sulfonatedtobias acid diazotized salt; and adding the sulfonated tobias acid diazotized salt into the mixed second condensate, carrying out a coupling reaction, and carrying out post-treatment so as to obtainthe reaction red dye. The preparation method provided by the invention is convenient and rapid, occupies few resources, has low energy consumption, and facilitates color matching.

Owner:ZHEJIANG JINGGUANG IND

Preparation method of pigment used for water-based ink

ActiveCN102311658BGood viscosity stabilityNo change in viscosityMonoazo dyesInksWater based2-Naphthol

The invention discloses a preparation method of a pigment used for water-based ink, which comprises the following steps: stirring 50-200 parts of water and 22 parts of sodium hydroxide, adding 22-24 parts of tobias acid and 0.1-2 parts of 2, 6 acid, dissolving, filtering, adding 28.4 parts of hydrochloric acid at the temperature of -3 to 2 DEG C, stirring, adding 30.4 parts of sodium nitrite solution, stirring at the temperature of 0-5 DEG C, adding 56 parts of calcium chloride solution, and stirring to obtain a solution I; stirring 200-720 parts of water and 24.5 parts of sodium hydroxide, adding 16 parts of 2-naphthol to dissolve at the temperature of 20-60 DEG C and filter, and adding 0.1-5.6 parts of rosin solution and 0.1-4 parts of turkey red oil solution into a filtrate at the temperature of 20-60 DEG C to obtain a solution II; adding the solution II into the solution I at the temperature of 0-5 DEG C to couple for 20 minutes, stirring for 30-60 minutes at the temperature of 10-15 DEG C, raising the temperature to 65-90 DEG C to transform completely, stirring for 10-30 minutes, filtering by pressing, washing filter cakes by water, and removing moisture in the filter cakes to obtain the pigment used for water-based ink. The viscosity stability of ink prepared from the pigment used for water-based ink disclosed by the invention is high, and after the treatment of 48 hours at the temperature of 50 DEG C, the viscosity is still basically unchanged.

Owner:LONGKOU UNION CHEM

A kind of system of industrial preparation 2-amino-5-naphthol-7-sulfonic acid

ActiveCN104945290BIncrease profitProcess conditions Environmental protection and energy savingSulfonic acids salts preparationSulfur-trioxide/sulfuric-acidFiltrationLiquid storage tank

The invention discloses a system for industrial preparation of 2-amino-5-naphtol7-sulfoacid. The system comprises a first synthesis reaction still, a second synthesis reaction still, a hydrolyzation reaction still, a regulation reaction still, a dissolution reaction still, a suction filtration reaction still, a concentration reaction still, a third synthesis reaction still, an acidification reaction still, a centrifugation reaction still, a drying reaction still, a finished product storage tank, a sewage treatment system, a Tobias acid liquid storage tank, a sulfur trioxide gas storage bottle, a concentrated sulfuric acid liquid storage tank, a sodium hydroxide solid storage tank, a hydrochloric acid liquid storage tank and a pure water storage pool. The 2-amino-5-naphtol7-sulfoacid prepared through the system is high in purity, the purity is over 92.8%, the water content is lower than 1%, the crystallizing rate is smaller than 0.5%, and free acid is smaller than 5%.

Owner:甘肃永鸿染化有限公司

Waste water treating and resourcelization method for tobias acid production

InactiveCN1323041CRealize resourcesPromote regenerationMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationTobias acid

The invention discloses a tobias acid production waste water controlling and resource recovering method, and the method regulates the pH value of the tobias acid production waste water, filters and makes main organic matters in the waste water absorbed on resin by the combination process of macroporous weakly basic resin and ultrahigh cross-linking absorption resin. The crude waste water: puce, chroma 1500-2000, iodinated tobias acid concentration 12000-15000 mg / L, tobias acid and 2, 1-acid concentration 6000-7000 mg / L, and COD 45000-5000 mg / L, and the processed waste water: chroma 10-50, iodinated tobias acid concentration < 500mg / L, tobias acid and 2, 1- acid concentration <50 mg / L, CODCr<1500mg / L, and the resins are regenerated by liquid alkali and water de-absorption, the high concentration deabsorption solution returns to amination stage of the tobias acid producing process, low concentration deabsorption solution is used indiscriminately in the next deabsoption operation, the sulphonated tobias acid is above 10 kg recovered from per cubic meter of waste water sample and the tobias acid is above 5 kg.

Owner:NANJING UNIV +1

Water-glycol type heat transfer medium with corrosion inhibition effect on galvanized pipe

ActiveCN111100608AImprove corrosion protection abilityGood corrosion inhibition effectHeat-exchange elementsThiazoleTobias acid

The invention relates to a water-glycol type heat transfer medium with a corrosion inhibition effect on a galvanized pipe. A corrosion inhibition component of the water-glycol type heat transfer medium comprises diphenolic acid, p-hydroxyphenylacetamide, tobias acid and 2, 4-dimethylthiazole. The brand-new heat transfer medium developed by the invention can significantly improve the corrosion inhibition protection capability of zinc, and has extremely significant zinc corrosion inhibition performance compared with existing similar coolant products.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of 2-bromo-6-fluoronaphthalene

InactiveCN101870636BShort synthetic routeMild conditionsOrganic compound preparationOrganic halogenationTobias acidBromine

Disclosed is a process for preparing 2-bromo-6-fluoronaphthalene, wherein the raw material is a Tobias acid, and the product is obtained by bromating-debrominating, diazotizating, and thermal decomposing. The product obtained by the present process has high purity and stable quality. Moreover, in the present process, the route is simple, the reaction condition is mild, and there is no need for high pressure. Therefore, the process is suitable for industrial production.

Owner:DATANGHANGZHOU PHARMACHEM

Process for producing J acid through mother liquor recycling and pressurized alkali fusion

PendingCN113429322AReduce cokingHigh yieldMagnesium sulfatesSulfonic acid preparationFluid phaseTobias acid

The invention belongs to the field of J acid preparation, and relates to a process for producing J acid through mother liquor recycling and pressurized alkali fusion; wherein tobias acid is sulfonated and then diluted with water instead of washing water containing sodium sulfate, it is avoided that sodium sulfate is contained in dilute sulfuric acid of amino J acid mother liquor, the amino J acid mother liquor can be used for producing magnesium sulfate, liquid-phase pressurized alkali fusion enables the reaction to be more thorough; and the material coking is avoided, the yield is improved, and the unit consumption of tobias acid is reduced by over 150kg compared with that of the traditional process. The strip liquor obtained by combining and extracting the amino J acid mother liquor is used for producing the water reducing agent, so that the materials are fully utilized.

Owner:SHANDONG CHUANGLAN YAOSHI ENVIRONMENTAL PROTECTION TECH CO LTD

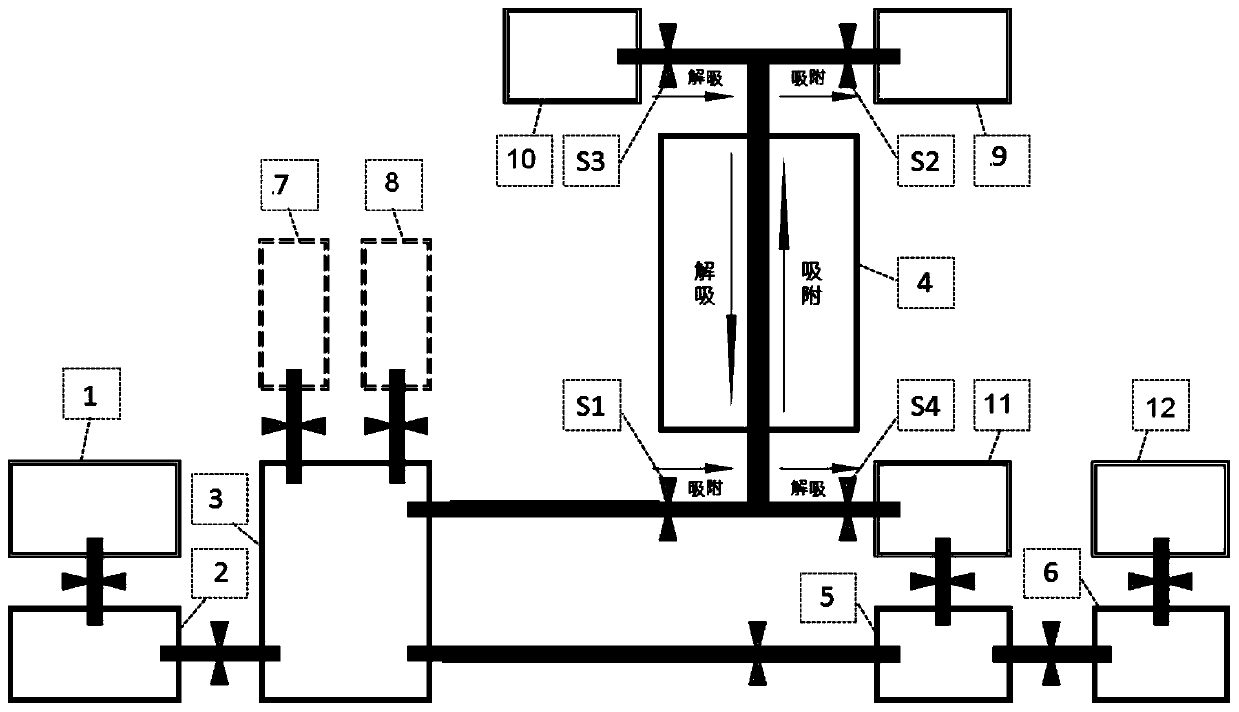

High-concentration COD wastewater recycling treatment system and method

ActiveCN109824155AThe adsorption efficiency does not changeGuaranteed reuseWater contaminantsMultistage water/sewage treatmentHigh concentrationTobias acid

The invention discloses a high-concentration COD wastewater recycling treatment system. The system comprises an extraction device and a COD resin adsorption column. The extraction device is provided with a wastewater inlet, an extracting agent inlet, a stripping agent inlet, a raffinate outlet and a strip liquor outlet. The COD resin adsorption column is provided with an adsorption water inlet, anadsorption water outlet, a back flushing fluid inlet and a reclaimed water outlet. The raffinate outlet is connected with the adsorption water inlet, the strip liquor outlet is connected with an acidification system, and the reclaimed water outlet is connected with the acidification system. Alkali serves as a stripping agent, and alkali solution serves as back flushing fluid. The system is simplein structure, and recycling of tobias acid and hydroxyl tobias acid in high-concentration COD wastewater, recovering of an extracting agent and regeneration of resin are realized. The invention further discloses a high-concentration COD wastewater recycling treatment method. Wastewater treated according to the method reaches discharge standards, and the recovery rate of tobias acid and hydroxyl tobias acid reaches 90% or above.

Owner:GUANGDONG YEANOVO ENVIRONMENTAL PROTECTION CO LTD

Method for preparing tobias acid by effective components extracted from waste water of tobias acid production

Owner:WUXI HUASHENG ENVIRONMENT PROTECTION TECH

A kind of method for preparing 2-amino-5-naphthol-7-sulfonic acid

InactiveCN105017095BIncrease profitProcess conditions Environmental protection and energy savingSulfonic acid preparationWater storage tankFiltration

The method discloses a method for preparing 2-amino-5-naphthol-7-sulfonic acid, and the method is implemented by using the following system. The system comprises a first synthesis reaction tower, a second synthesis reaction tower, a hydrolysis reaction tower, an adjustment reaction tower, a dissolution reaction tower, a suction filtration reaction tower, a concentration reaction tower, a third synthesis reaction tower, an acidification reaction tower, a centrifugation reaction tower, a drying reaction tower, a finished product storage tank, a wastewater treatment system, a tobias acid liquid storage tank, a sulfur trioxide gas storage tank, a concentrated sulfuric acid liquid storage tank, a sodium hydroxide solid storage tank, a hydrochloric acid liquid storage tank, and a pure water storage tank. The 2-amino-5-naphthol-7-sulfonic acid product prepared by the method disclosed by the invention has high purity which is greater than 92.8%, the moisture content is less than 1%, the crystallization rate is less than 0.5%, and the free acid is less than 5%.

Owner:王汝环

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com