Preparation method for reaction red dye

A technology of reactive scarlet and dyes, which is applied in the field of preparation of reactive scarlet dyes, can solve the problems of large resource occupation, difficulty in color matching, high energy consumption, etc., and achieve the effects of less resource occupation, convenient production, and avoiding excessive resource occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

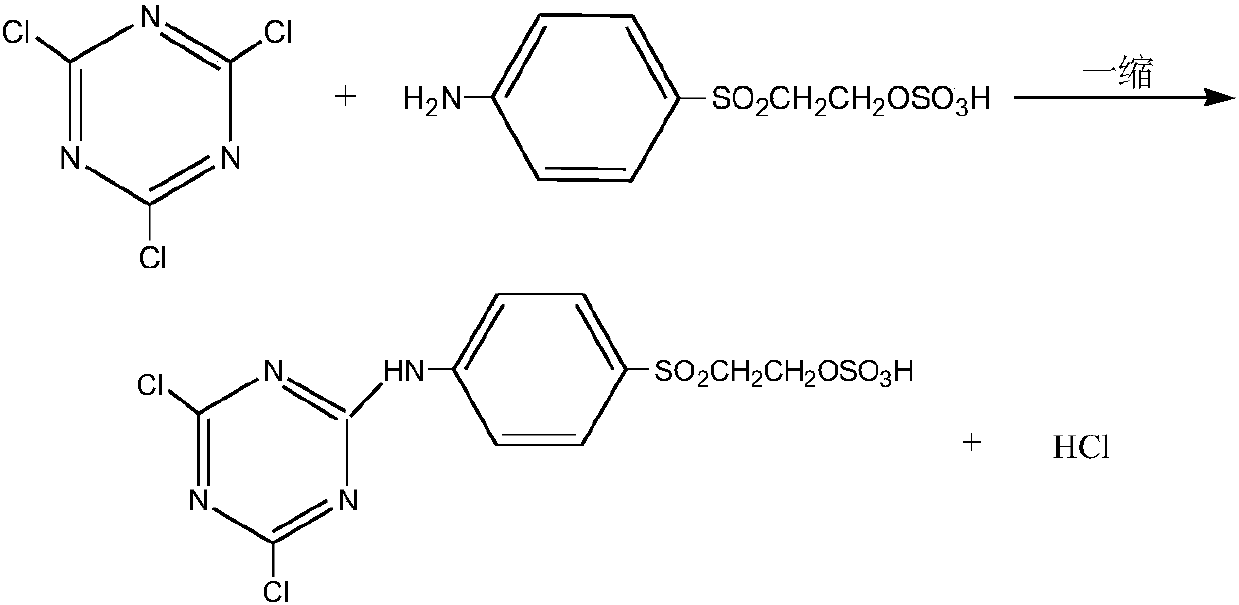

[0045] Process 1, cyanuric chloride beating

[0046] Add 800 kg of industrial cyanuric chloride solids and 10 kg of dispersant C into a FRP reaction pot containing 2000 kg of water and 3000 kg of ice, beat and stir for 1 hour, and add a small amount of 30% hydrochloric acid according to the actual pH value Control pH=2~2.5, control temperature 0~5℃.

[0047] Step 2, a condensation reaction

[0048]Then add 1242 kg of solid para-ester (amino content ≥ 96%), after fully stirring, add the mass fraction of 10% mixed alkali solution prepared by soda ash and baking soda (mass ratio 3:7), dropwise To the above-mentioned condensate, (the titration rate is 500L / 10min respectively), the temperature of the addition process is controlled to be lower than 3°C (if the temperature is high, ice should be replenished, otherwise the reaction will be affected), the pH value reaches about 1.0, and the remaining mixed alkali is within 10 to 20 minutes. Adjust the pH to 4.0. When the pH naturally...

Embodiment 2

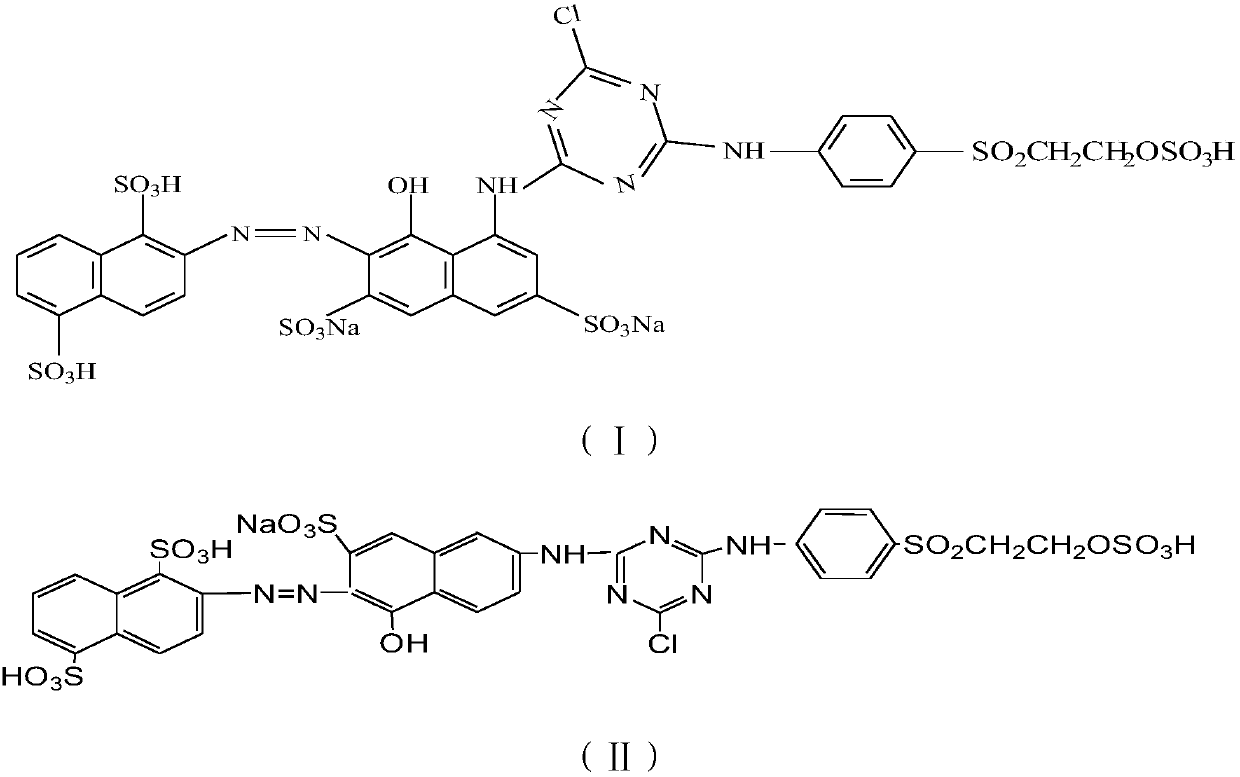

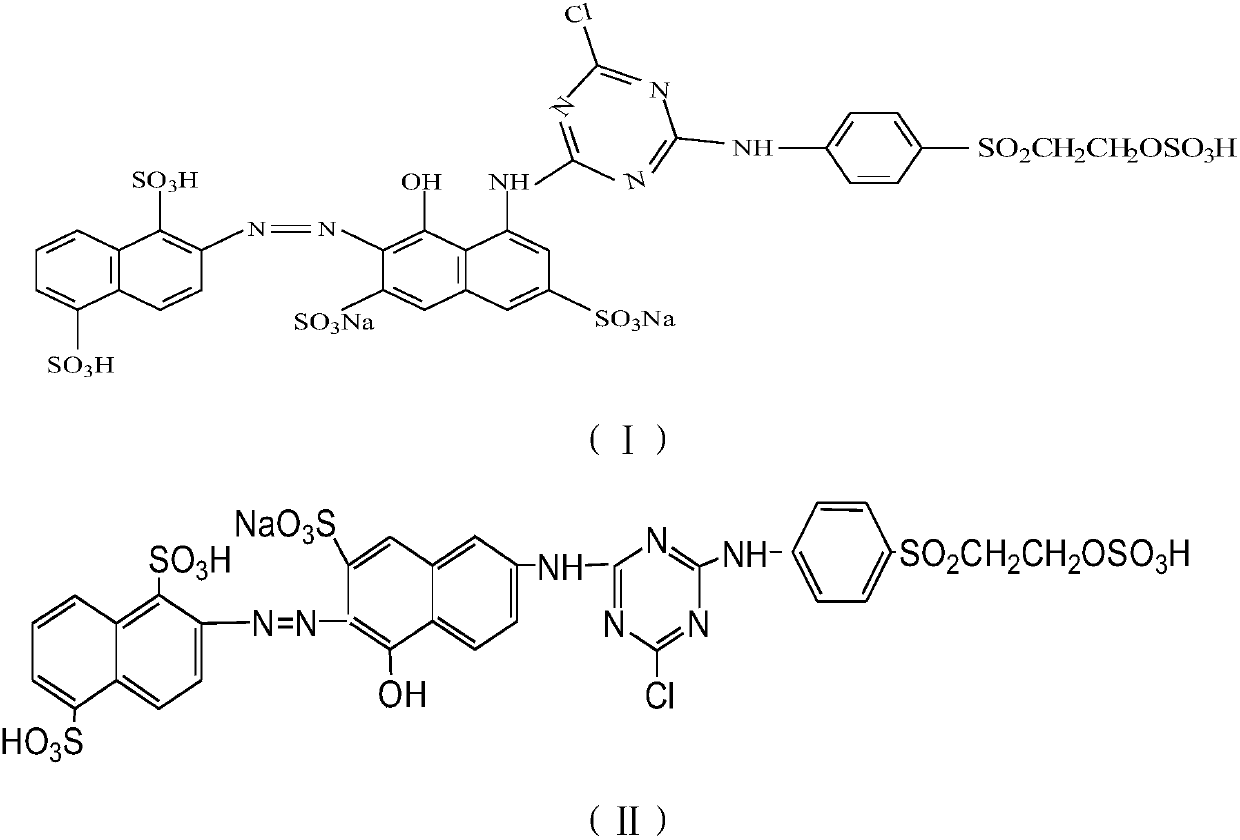

[0059] Prepare according to the preparation process of Example 1, the difference is that once the shrinkage hydrolysis is completed, the dosage of J acid and H acid dry powder is 589 kg and 445 kg respectively, and finally the scarlet reactive dye is obtained. After HPLC analysis, the formula I compound and The molar ratio of the compound of formula II is approximately 0.34:0.66.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com