Method for preparing polar solvent soluble nano ferriferrous oxide granule

A technology of ferric oxide and polar solvents, applied in the field of nanometers, can solve the problems of difficult to disperse particles, easy agglomeration of particles, fast reaction speed, etc., and achieve uniform particle size distribution, good dispersibility, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 0.05molFeCl 3 ·6H 2 O and 0.025mol FeCl 2 4H 2 O, dissolved in 10ml of water to obtain iron salt solution, measure 2ml of diisopropylamine in a graduated cylinder, and dissolve in 30ml of n-hexane. Under the condition of nitrogen protection, the aqueous solution of the iron salt was slowly dropped into the diisopropylamine / n-hexane solution, the temperature was controlled at 25° C., and the whole reaction lasted for 1 hour. After the reaction product was taken out, the reaction product was washed once with acetone by centrifugation (11,000 rpm, 10 minutes), and the black powder was obtained after vacuum freeze-drying for 12 hours, which was nanometer ferric oxide particles.

[0017] The obtained black powder can be determined as ferric oxide particles with inverse spinel structure by X-ray diffraction (XRD), and its purity is very high.

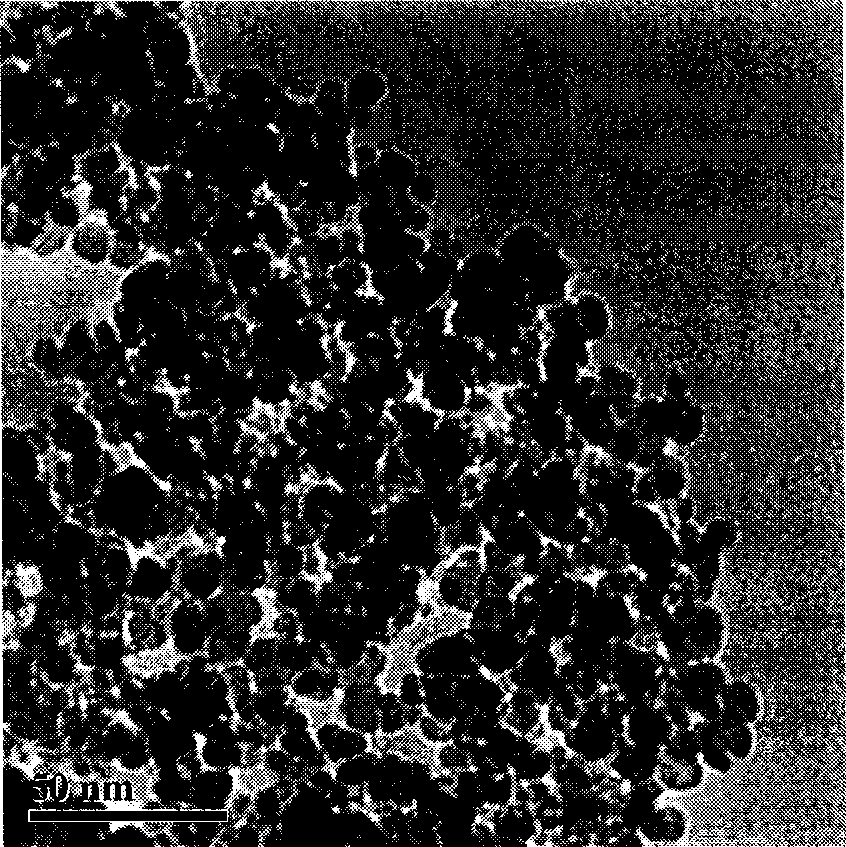

[0018] The as-prepared particles were observed by transmission electron microscopy, as figure 1 As shown, it can be seen t...

Embodiment 2

[0022] Weigh 0.05molFeCl 3 ·6H 2 O and 0.025mol FeCl 2 4H 2 O, dissolved in 100ml of water to obtain iron salt solution, measure 10ml of diisobutylamine in a graduated cylinder, and dissolve in 300ml of n-heptane. Under the condition of nitrogen protection, the diisobutylamine / n-heptane solution was slowly dropped into the aqueous solution of iron salt, the temperature was controlled at 50°C, and the whole reaction lasted for 0.5 hours. After the reaction product was taken out, the reaction product was washed once with acetone by centrifugation (11000 rpm, 10 minutes), then washed five times with deionized water, and then vacuum freeze-dried for 24 hours to obtain a black powder, which was nanometer ferric oxide particles.

[0023] The obtained black powder can be determined as ferric oxide particles with inverse spinel structure by X-ray diffraction (XRD), and its purity is very high.

[0024] Observing the prepared particles with a transmission electron microscope, it ca...

Embodiment 3

[0028] Weigh 0.2molFeCl 3 ·6H 2 O and 0.1mol FeCl 2 4H 2 O, dissolved in 100ml of water to obtain iron salt solution, measure 50ml of di-n-butylamine in a graduated cylinder, and dissolve in 1000ml of n-hexane. Under the condition of nitrogen protection, the di-n-butylamine / n-hexane solution was slowly dropped into the aqueous solution of iron salt, the temperature was controlled at 60° C., and the whole reaction lasted for 10 hours. After taking out the reaction product, adopt centrifugation method (11000 rev / min, 10 minutes) to wash 5 times with acetone, then wash 5 times with deionized water, obtain black powder after 18 hours of vacuum freeze-drying, be nano ferric oxide particles.

[0029] The obtained black powder can be determined as ferric oxide particles with inverse spinel structure by X-ray diffraction (XRD), and its purity is very high.

[0030] Observing the prepared particles with a transmission electron microscope, it can be seen that the prepared ferric oxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com