Method for preparing tobias acid by effective components extracted from waste water of tobias acid production

A technology for the production of waste water and active ingredients, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems affecting the quality of tunic acid products, the increase of impurity content, and the accumulation of impurities in the stripping solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

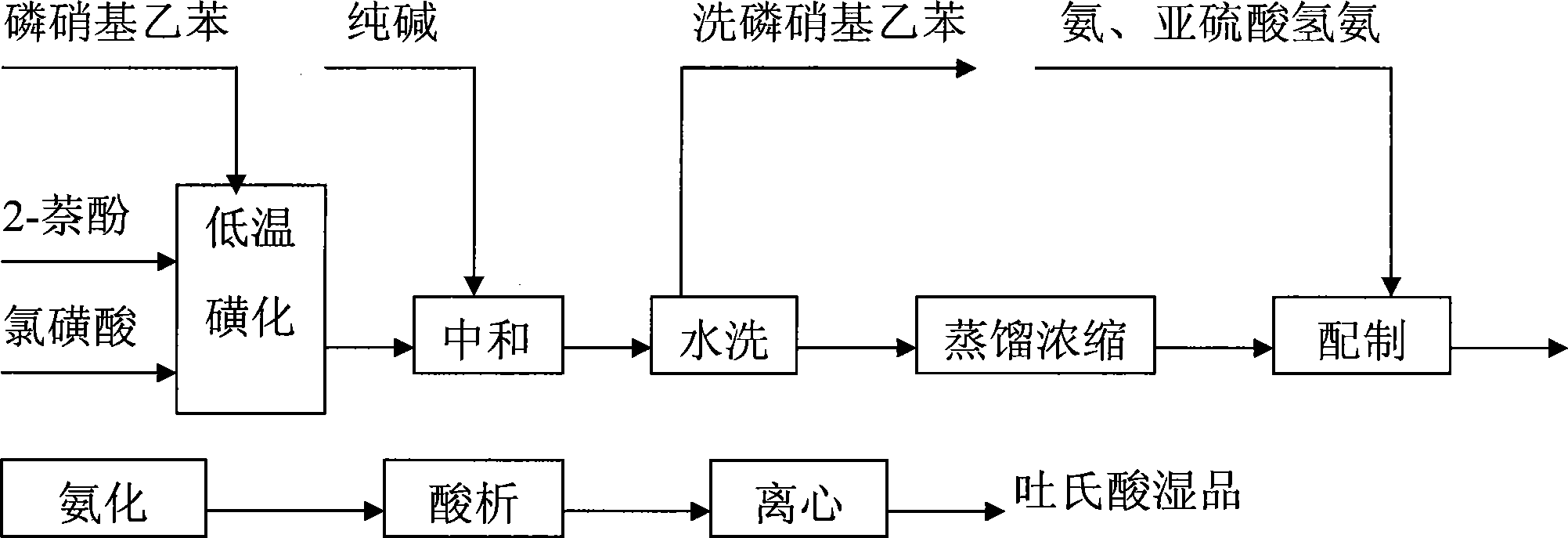

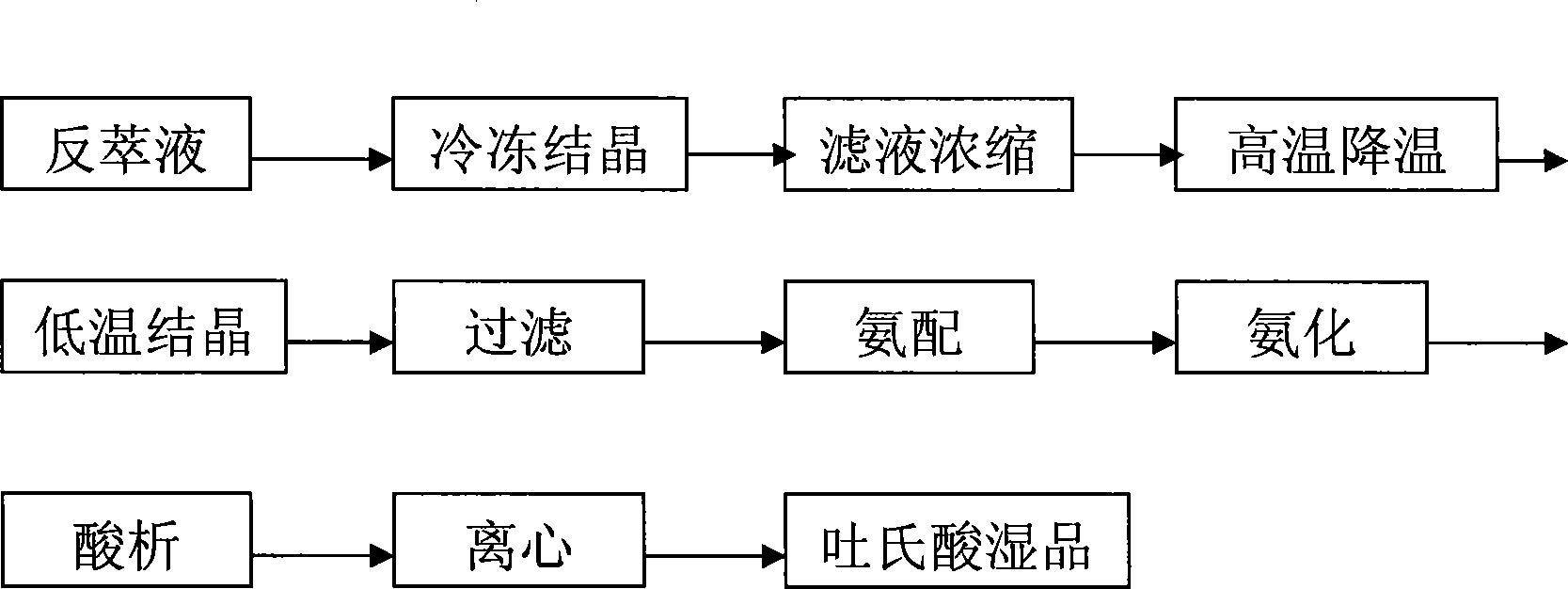

Method used

Image

Examples

Embodiment 1

[0027] 1000 milliliters of stripping solution was cooled to 0° C. and kept for 12 hours, then 105 grams of Glauber’s salt was filtered off to obtain 900 milliliters of denitrification solution, which was distilled in a retort to remove 450 milliliters of water. The room temperature was naturally cooled to 22° C., and filtered to obtain 150 grams of filter cake with a water content of 20%. After the filter cake is mixed with ammonia, it is transferred to a 1000ml autoclave for ammoniation, the temperature is raised to 160°C, and the temperature is kept for 8 hours. The ammonia is discharged and the temperature is lowered to 100°C. 1:1 hydrochloric acid acid analysis to PH=1~2. Filtration and washing resulted in fine granular tunic acid crystals. After drying, 72 g of the product was obtained with a purity of 99.21% (as determined by HPLC).

[0028] Implementation column 2:

[0029] Take 1000 ml of back-extraction solution, cool to ~2°C, keep warm for 3 hours, filter out 120 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com