A kind of cementitious material for low-alkali, reinforced plant-growing concrete and preparation method thereof

A technology of planting concrete and cementitious materials, applied in cementitious materials for reinforced planting concrete and its preparation, and in the field of low alkalinity, it can solve the problems of high alkalinity of planting concrete, and achieve the effects of strong durability, increased activity, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A low-alkali, reinforced cementitious material for plant-growing concrete. The gelatinous material is prepared from the following raw materials in parts by weight: 71 parts of α-hemihydrate gypsum, 28 parts of metakaolin, 0.7 part of citric acid and polycarboxylic acid The composition of 0.3 parts of water agent.

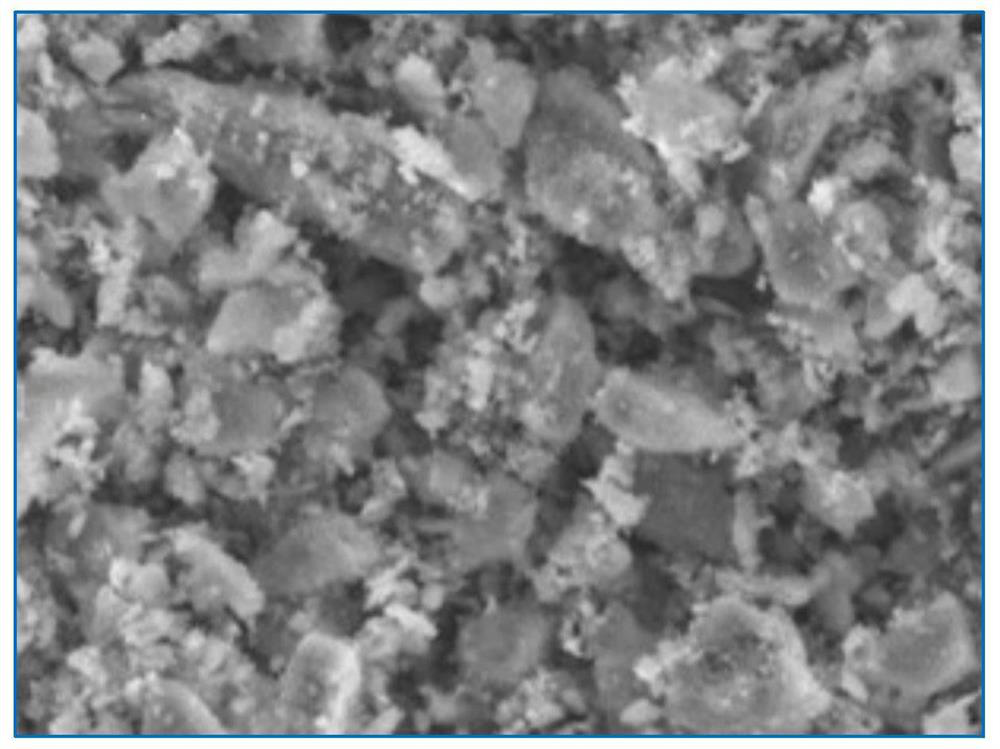

[0027] The preparation of the α-hemihydrate gypsum is to use natural dihydrate gypsum as a raw material, which is generated in a saturated water vapor autoclave environment at 1.35 atmospheric pressure and a temperature of 130 ° C. CaO and SO 3 The contents are 37.5% and 52.3%, respectively.

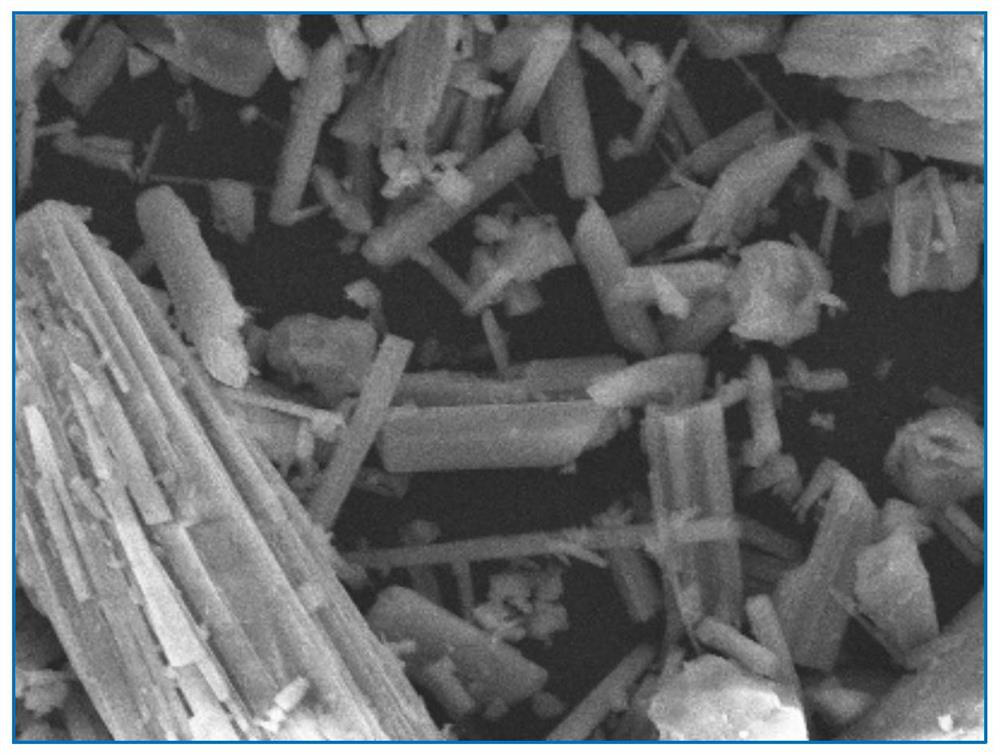

[0028] The metakaolin is made of kaolin as a raw material, which is dehydrated by calcining at 750°C for 5 hours to form a metastable high-activity admixture, wherein SiO in metakaolin 2 and Al 2 o 3 The contents are 58.2% and 37.1% respectively, and the whiteness is 73%.

Embodiment 2

[0030] A low-alkali, reinforced cementitious material for plant-growing concrete. The gelatinous material is prepared from the following raw materials in parts by weight: 75 parts of α-hemihydrate gypsum, 24 parts of metakaolin, 0.7 part of citric acid and polycarboxylic acid The composition of 0.3 parts of water agent.

[0031] The preparation of the α-hemihydrate gypsum is to use natural dihydrate gypsum as a raw material, which is generated in a saturated water vapor autoclave environment at 1.2 atmospheric pressure and a temperature of 145°C, wherein CaO and SO 3 The contents are 35.8% and 50.9%, respectively.

[0032] The metakaolin is made of kaolin as a raw material, which is dehydrated by calcining at 700°C for 6 hours to form a metastable high-activity admixture, wherein SiO in metakaolin 2 and Al 2 o 3 The content is 53.6% and 37.6%, and the whiteness is 68%.

Embodiment 3

[0034] A low-alkali, reinforced cementitious material for plant-growing concrete. The gelatinous material is prepared from the following raw materials in parts by weight: 82 parts of α-hemihydrate gypsum, 16 parts of metakaolin, 1.4 parts of citric acid and polycarboxylate The water formulation consists of 0.6 parts.

[0035] The preparation of the α-hemihydrate gypsum is to use natural dihydrate gypsum as a raw material, which is generated in a saturated water vapor autoclave environment at 1.2 atmospheric pressure and a temperature of 145°C, wherein CaO and SO 3 The content was increased from %, % to 35.8% and 50.9% respectively.

[0036] The metakaolin is made of kaolin as a raw material, which is dehydrated by calcining at 700°C for 6 hours to form a metastable high-activity admixture, wherein metakaolin SiO 2 and Al 2 o 3 The content is more than 53.6% and 37.6%, and the whiteness is 68%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com