Environmentally friendly medical hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive, environmentally friendly technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of unfavorable dissolution and release of non-polar drugs, complicated use process, low drug loading, etc. Achieve the effect of benefiting drug development, high drug loading, enhanced chemical stability and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

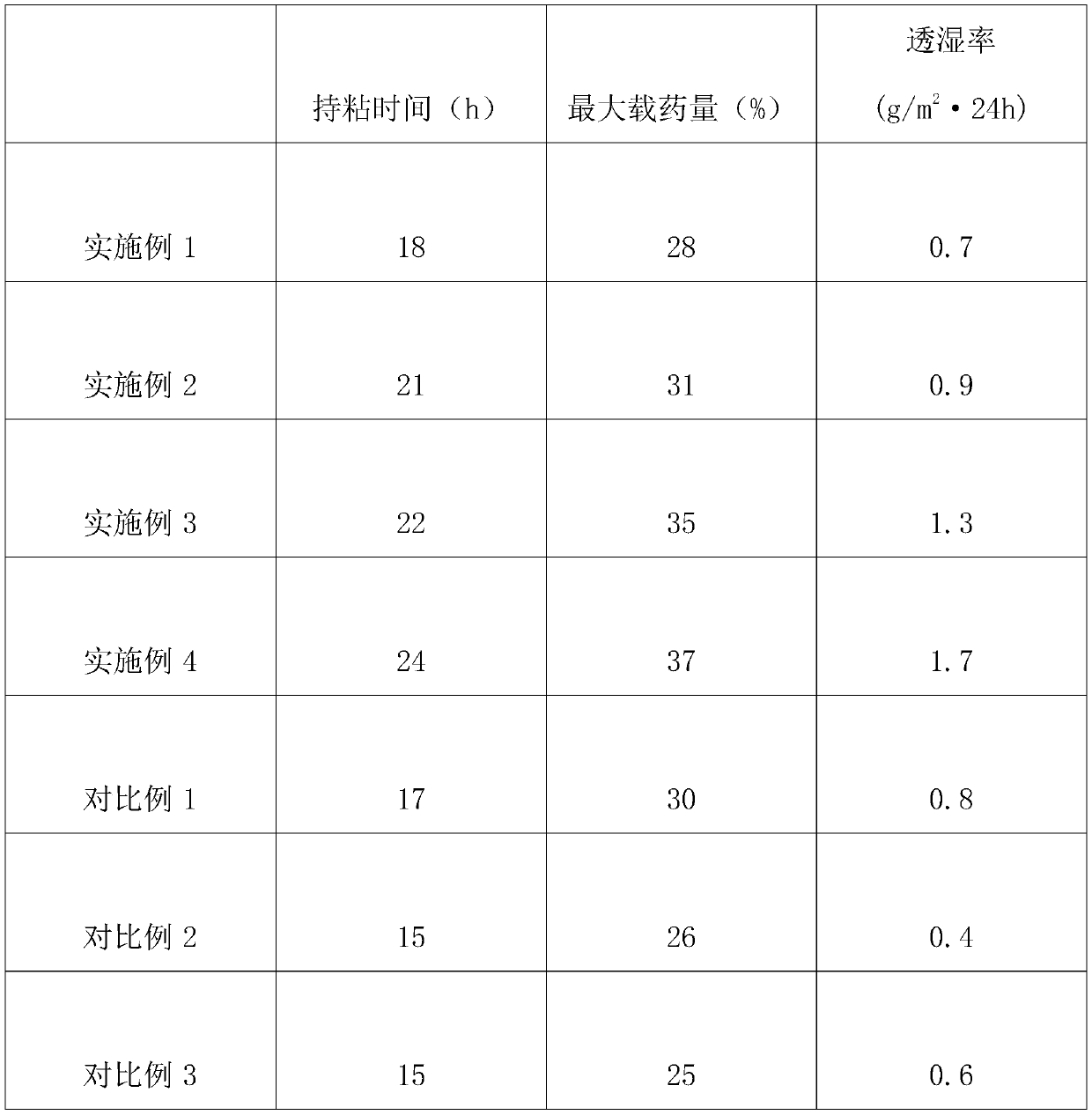

Examples

Embodiment 1

[0034] An environment-friendly medical hot-melt pressure-sensitive adhesive, made of the following raw materials in parts by weight: 55 parts of styrene-isoprene-styrene thermoplastic elastomer, 35 parts of modified acrylic resin, 25 parts of mixed rubber, 3 parts Butylated hydroxytoluene, 5 parts of rosin, 50 parts of deionized water, 35 parts of white oil;

[0035] The environment-friendly medical hot-melt pressure-sensitive adhesive is made by the following steps:

[0036] Step S1. Mix styrene-isoprene-styrene thermoplastic elastomer and modified acrylic resin and add it to the internal mixer. Control the roller distance to 3.5 mm, and the temperature is 80 ° C. After stirring for 30 minutes, add dibutyl hydroxyl Toluene, heated up to 150°C, and the mixture was prepared after 45 minutes of compacting;

[0037] Step S2: Put the mixed rubber and rosin into a three-necked flask, add deionized water and white oil, soak for 5 hours, pass in nitrogen, heat to 120°C, keep warm fo...

Embodiment 2

[0048] An environment-friendly medical hot-melt pressure-sensitive adhesive, made of the following raw materials in parts by weight: 60 parts of styrene-isoprene-styrene thermoplastic elastomer, 40 parts of modified acrylic resin, 30 parts of mixed rubber, 5 parts Butylated hydroxytoluene, 7 parts of rosin, 53 parts of deionized water, 40 parts of white oil;

[0049] The environment-friendly medical hot-melt pressure-sensitive adhesive is made by the following steps:

[0050] Step S1. Mix styrene-isoprene-styrene thermoplastic elastomer and modified acrylic resin and add it to the internal mixer. Control the roller distance to 3.5 mm, and the temperature is 80 ° C. After stirring for 30 minutes, add dibutyl hydroxyl Toluene, heated up to 150°C, and the mixture was prepared after 45 minutes of compacting;

[0051] Step S2: Put the mixed rubber and rosin into a three-necked flask, add deionized water and white oil, soak for 5 hours, pass in nitrogen, heat to 120°C, keep warm fo...

Embodiment 3

[0054] An environment-friendly medical hot-melt pressure-sensitive adhesive, made of the following raw materials in parts by weight: 65 parts of styrene-isoprene-styrene thermoplastic elastomer, 50 parts of modified acrylic resin, 40 parts of mixed rubber, 7 parts Butylated hydroxytoluene, 8 parts of rosin, 58 parts of deionized water, 45 parts of white oil;

[0055] The environment-friendly medical hot-melt pressure-sensitive adhesive is made by the following steps:

[0056] Step S1. Mix styrene-isoprene-styrene thermoplastic elastomer and modified acrylic resin and add it to the internal mixer. Control the roller distance to 3.5 mm, and the temperature is 80 ° C. After stirring for 30 minutes, add dibutyl hydroxyl Toluene, heated up to 150°C, and the mixture was prepared after 45 minutes of compacting;

[0057] Step S2: Put the mixed rubber and rosin into a three-necked flask, add deionized water and white oil, soak for 5 hours, pass in nitrogen, heat to 120°C, keep warm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com