A kind of high-temperature lubricating grease for kiln car and preparation method thereof

A lubricating grease and high-temperature technology, which is applied in the field of high-temperature lubricating grease for kiln cars and its preparation, can solve problems such as kiln car bearing stuck production and loss, and achieve benefits for subsequent reactions, increase saturation, and enhance wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

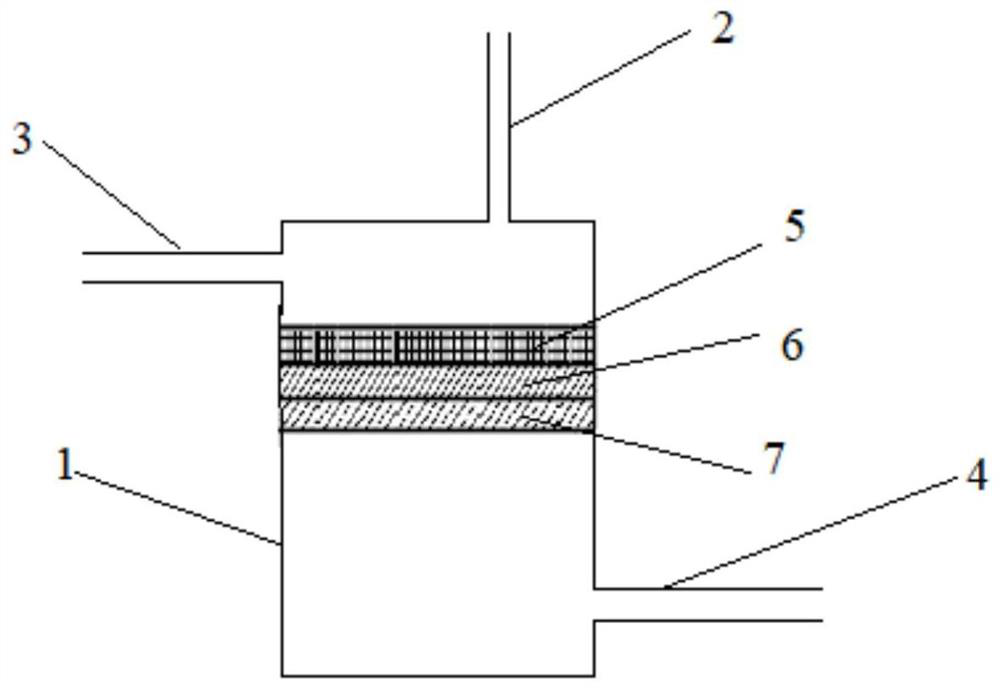

Image

Examples

preparation example Construction

[0046] Simultaneously, a kind of preparation method of kiln car high-temperature lubricating grease of the present invention comprises the following steps:

[0047] (1) Preparation of base oil A: Add castor oil into the oxidation kettle, heat and stir for 30 minutes, then introduce oxygen, react for 12~20 hours, and remove the prepared material from the outlet;

[0048] (2) Preparation of thickener: Add polyabbietic acid into the reaction vessel, add polyamine drop by drop, and react at 220~250°C;

[0049] (3) Add base oil A and base oil B into the reaction kettle in proportion, and raise the temperature to 100~150°C;

[0050] (4) Add the thickener in proportion to the kettle, and continue to heat up to 180~200°C;

[0051] (5) Add ethylene glycol, antioxidant, antirust agent, and extreme pressure antiwear agent to the material obtained in step (4), lower the temperature to 100~140°C, and react for 0.5~1h;

[0052] (6) Continue to cool down to 80-100°C, and after 1-2 hours of...

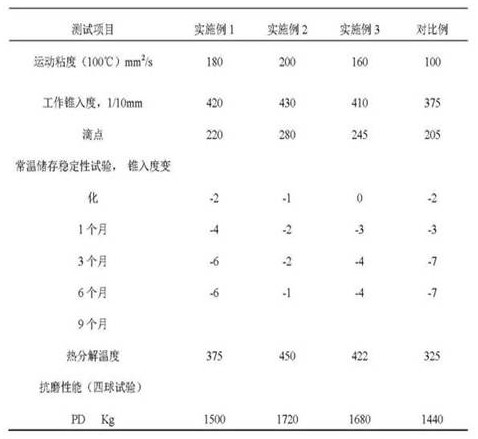

Embodiment 1

[0054] A kind of high-temperature lubricating grease for kiln car of the present invention is prepared by comprising the following components in parts by weight:

[0055] 20 parts of base oil A; 30 parts of mineral oil; 5 parts of ethylene glycol; 20 parts of dibasic abietic acid; 10 parts of diethylenetetramine; 1 part of diphenylamine; 1 part of alkenyl succinic acid; .

[0056] A kind of preparation method of kiln car high temperature lubricating grease of the present invention comprises the following steps:

[0057] (1) Preparation of base oil A: Add castor oil into the oxidation kettle, heat and stir for 30 minutes, then inject oxygen, react for 12 hours, and remove the prepared material from the discharge port;

[0058] (2) Preparation of thickener: Add binary abietic acid into the reaction vessel, add diethylenetetramine dropwise, and react at 220°C;

[0059] (3) Add 20g of oxidized castor oil and 30g of mineral oil into the reaction kettle in proportion, and raise th...

Embodiment 2

[0065] A kind of high-temperature lubricating grease for kiln car of the present invention is prepared by comprising the following components in parts by weight:

[0066] 50 parts of base oil A; 20 parts of mineral oil; 10 parts of ethylene glycol; 10 parts of dibasic abietic acid; 10 parts of diethylenetetramine; 5 parts of diphenylamine; .

[0067] A kind of preparation method of kiln car high temperature lubricating grease of the present invention comprises the following steps:

[0068] (1) Preparation of base oil A: Add 50g of castor oil into the oxidation kettle, heat and stir for 30min, then inject oxygen, react for 20h, and remove the prepared material from the outlet;

[0069](2) Preparation of thickener: Add binary abietic acid into the reaction vessel, add diethylenetetramine dropwise, and react at 250°C;

[0070] (3) Add 50g of oxidized castor oil and 20g of mineral oil into the reaction kettle in proportion, and raise the temperature to 150°C;

[0071] (4) Add 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com