Destressing process for ultrahigh-vacuum stainless steel cavity components

An ultra-high vacuum and stainless steel technology, applied in the field of stress relief technology, can solve problems such as increasing operating costs of enterprises, achieve the effects of preventing deformation and cracking, reducing peak stress, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

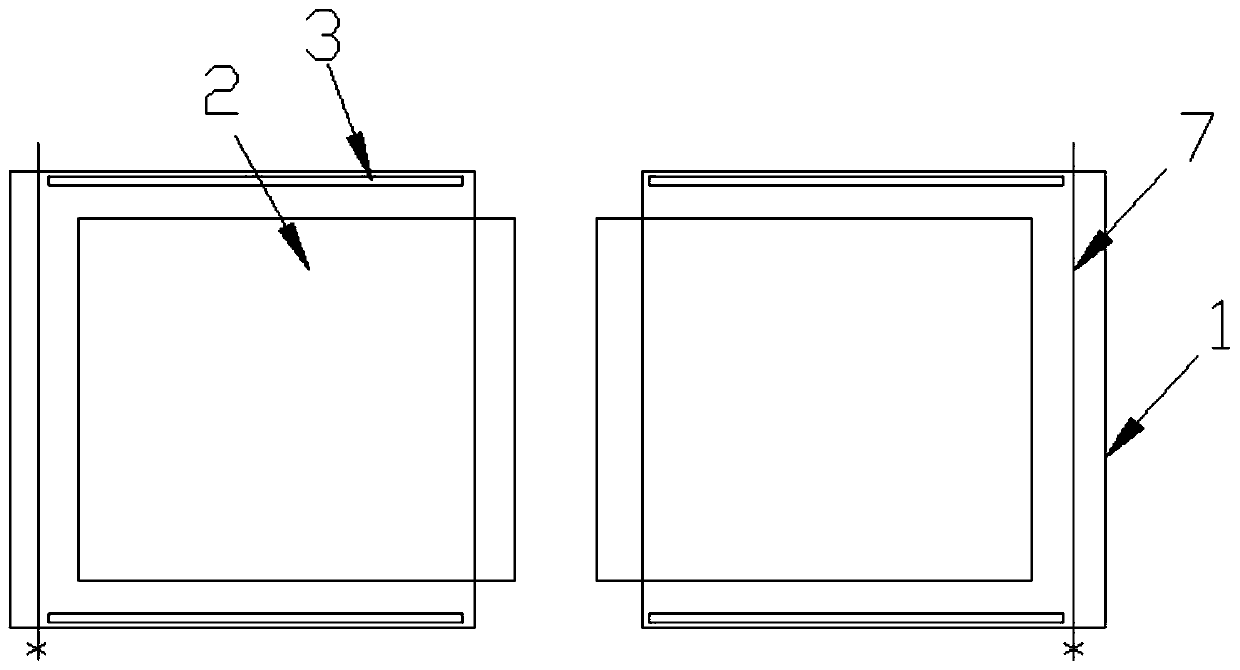

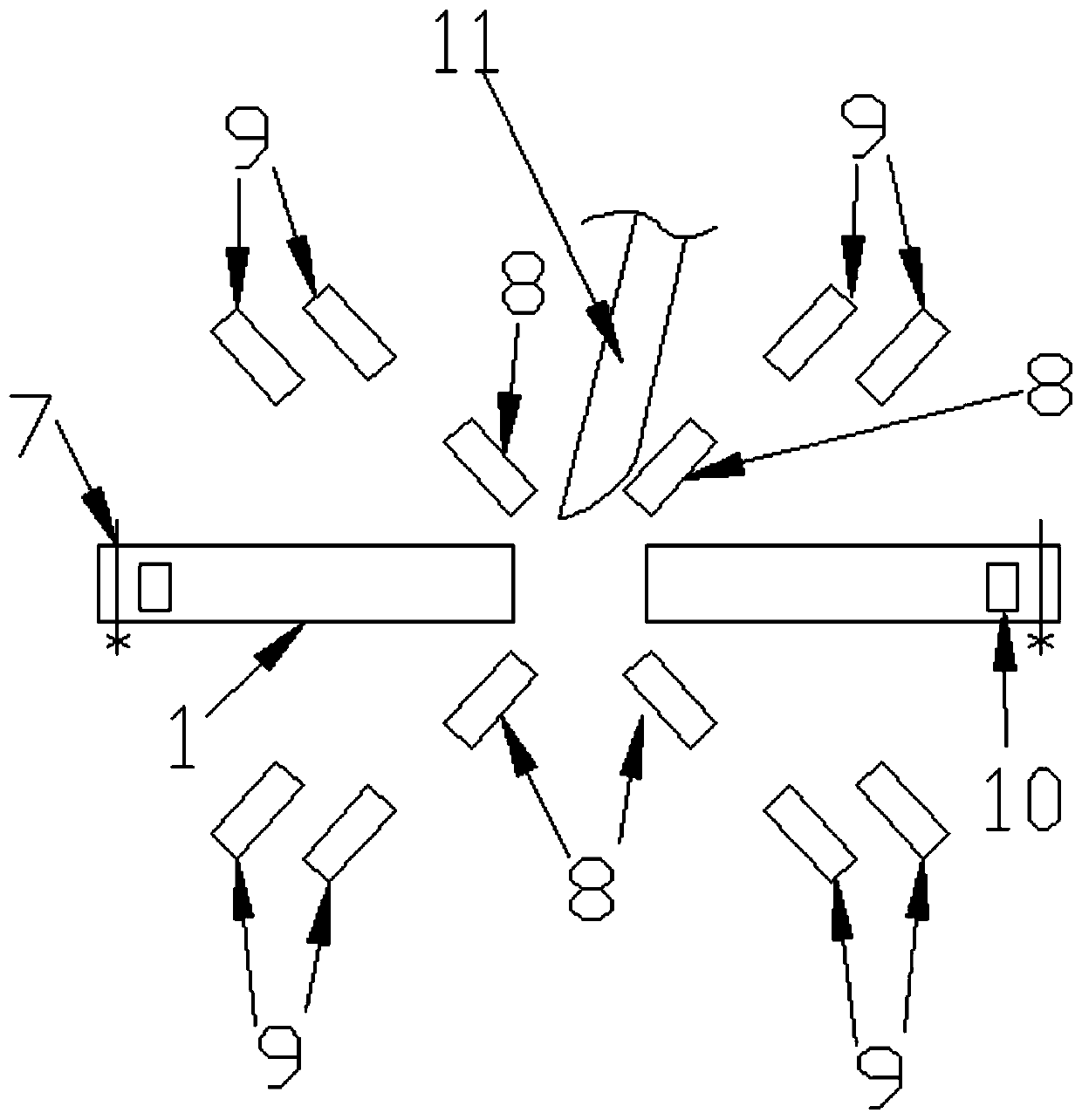

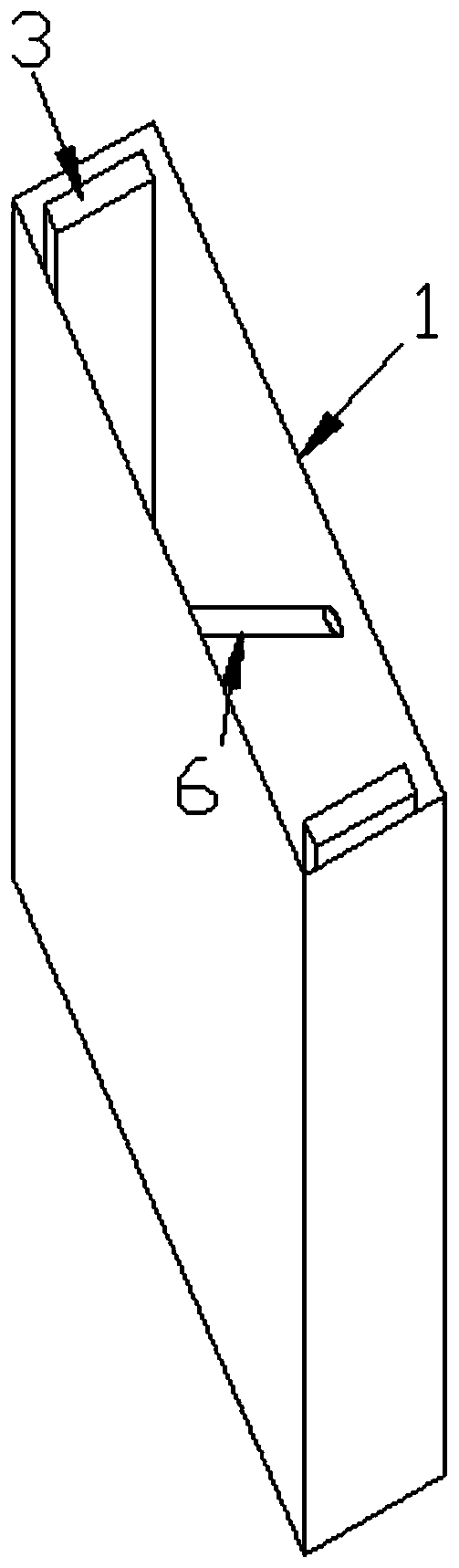

[0035] The present invention is a stress relief process for ultra-high vacuum stainless steel chamber components, such as Figure 1 to Figure 8 As shown, including the following process steps:

[0036] S1: When the stainless steel vacuum chamber plate 2 is welded, a flexible heat-insulating insulating sleeve 1 is set on the two plates, and the distance between the two flexible heat-insulating insulating sleeves 1 near the end of the weld is greater than that of the two plates after welding the width of the weld;

[0037] S2: After the flexible heat-insulating insulating sleeve 1 is set on the plate 2, the protruding rod 12 is fixedly connected to the lower part of the welding torch 11. Knock the bottom surface of the piece but the bottom end of the protruding rod 12 is provided with a distance from the surface of the plate 2; The top-facing blower 9 at the high altitude at the place and open the exhaust fan 10 at the end of the two flexible heat-insulating insulation sleeves...

Embodiment 2

[0041] The difference from Embodiment 1 is that, as Figure 9 , Figure 10 As shown, in the S3 step, the stress-relief tooling includes a rubber pad 16, a profiled cover 17 and a camera 18 matched with the profiled cover 17, the profiled cover 17 is oil clay, and the welded After the workpiece is placed on the rubber pad 16, cover the surface of the workpiece with oil clay and use the camera 18 to take pictures, turn on the vibrator 13 and start it for 5-10 minutes, then turn off the vibrator 13, then use the camera 18 to take pictures again, and compare the two images Find the peak and nodal line when the workpiece resonates, determine the best placement position and placement angle according to the peak and nodal line when the workpiece resonates, and start the vibrator 13 again after adjusting the workpiece to perform vibration stress relief.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com