An air source large temperature span high temperature heat pump drying system

A high-temperature heat pump and drying system technology, applied in heat recovery systems, heat pumps, drying, etc., can solve the problems of difficult realization and high cost of heat pump single-stage compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

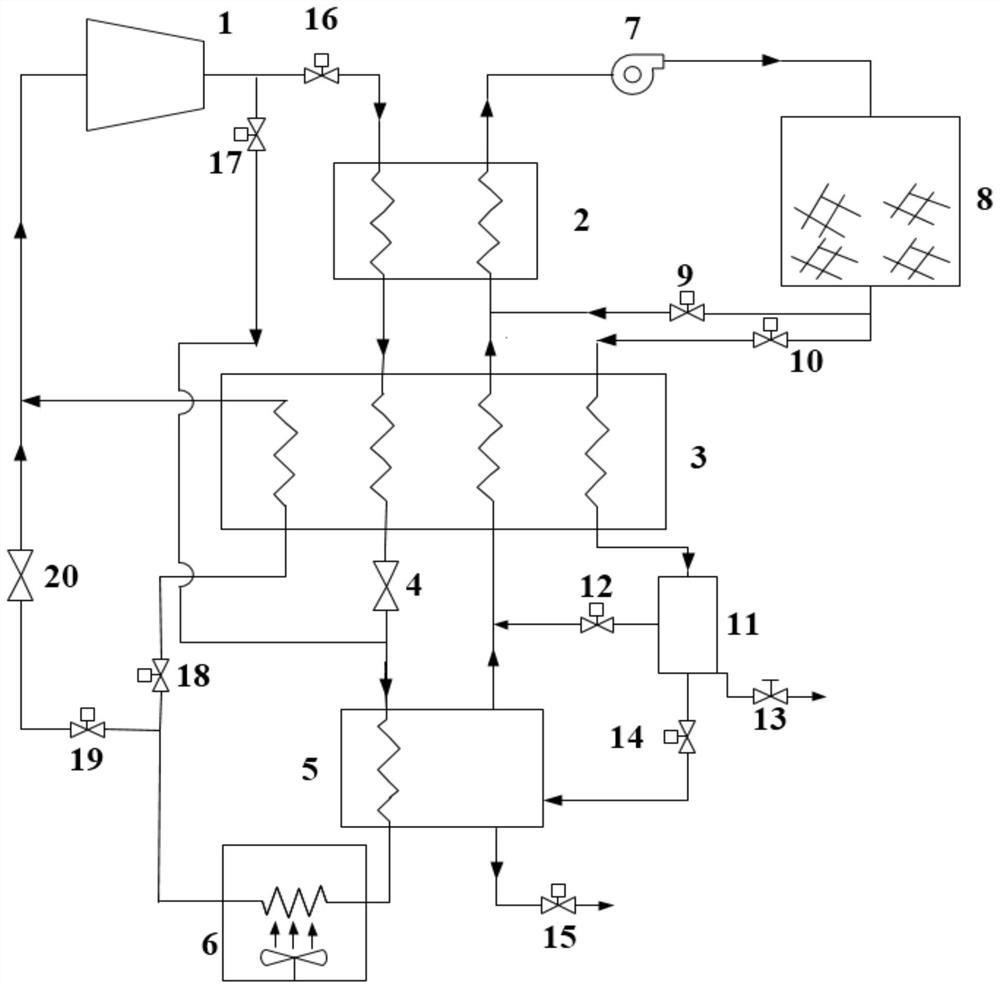

[0041] see figure 1 For Embodiment 1 of the present invention, a schematic structural diagram of a heat pump drying system with air source, large temperature span, and high temperature is provided. For the convenience of description, only the parts related to the embodiment of the present invention are shown, and the details are as follows.

[0042] The air source large temperature span high temperature heat pump drying system provided by the present invention includes: a compressor 1, a fan 7, a drying chamber 8, an evaporator 6, a condenser 2, a regenerative heat exchanger 3, a first throttling element 4, a second Two throttling elements 20, the first stop valve 9, the second stop valve 10, the third stop valve 12, the fourth stop valve 14, the fifth stop valve 16, the sixth stop valve 17, the seventh stop valve 18, the eighth stop valve The shut-off valve 19 , the first condensate-trap separator 11 , the second condensate-trap separator 5 , the first drain valve 13 and the ...

Embodiment 2

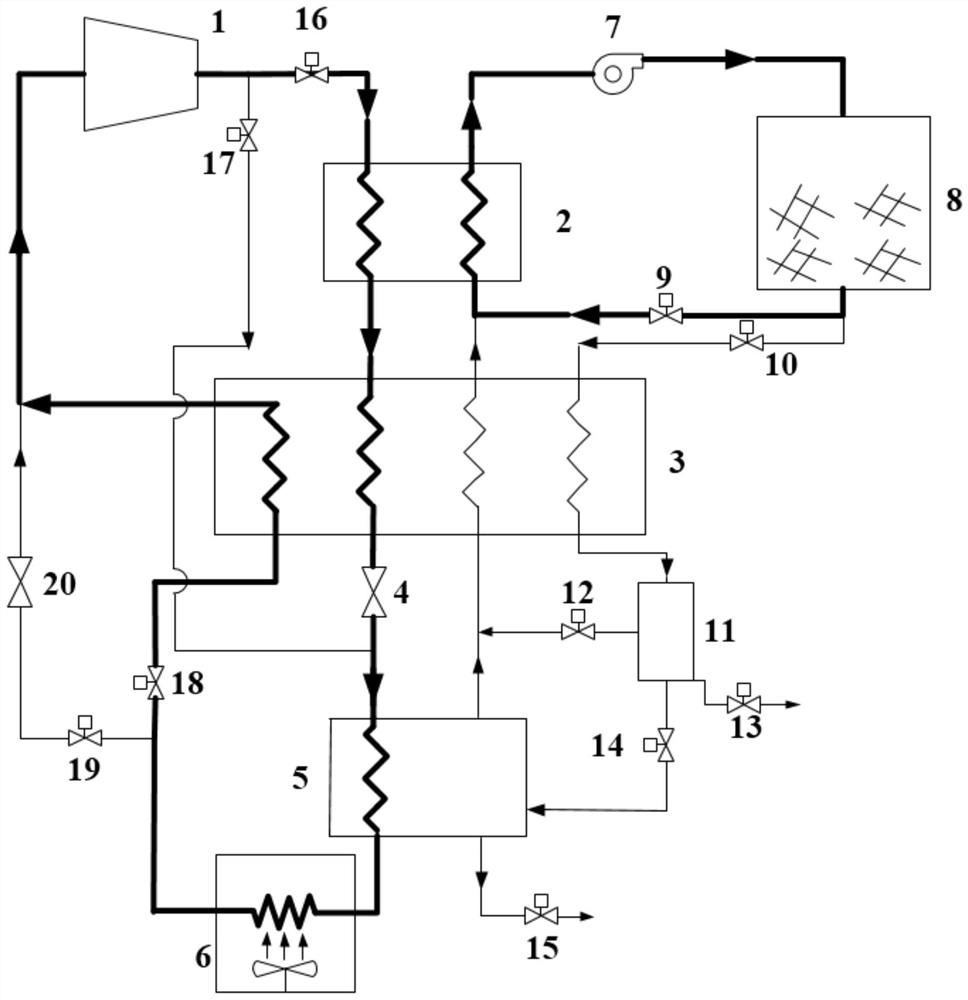

[0057] see figure 2 , is a schematic diagram of the preheating mode of the air source large temperature span high temperature heat pump system provided by an embodiment.

[0058] The air source large temperature span high temperature heat pump drying system includes a preheating mode, and the working mode of the preheating mode is as follows:

[0059] The first shut-off valve 9 is opened, the fifth shut-off valve 16 is opened, the seventh shut-off valve 18 is opened, the second shut-off valve 10 is closed, the third shut-off valve 12 is closed, the fourth shut-off valve 14 is closed, and the sixth shut-off valve 17 is closed , the eighth shut-off valve 19 is closed, the second liquid discharge valve 15 is closed, the high-temperature working fluid discharged from the high-pressure outlet of the compressor 1 enters the condenser 2 to heat the air through the fifth shut-off valve 16, and then enters the The regenerative heat exchanger 3 passes through the first throttling elem...

Embodiment 3

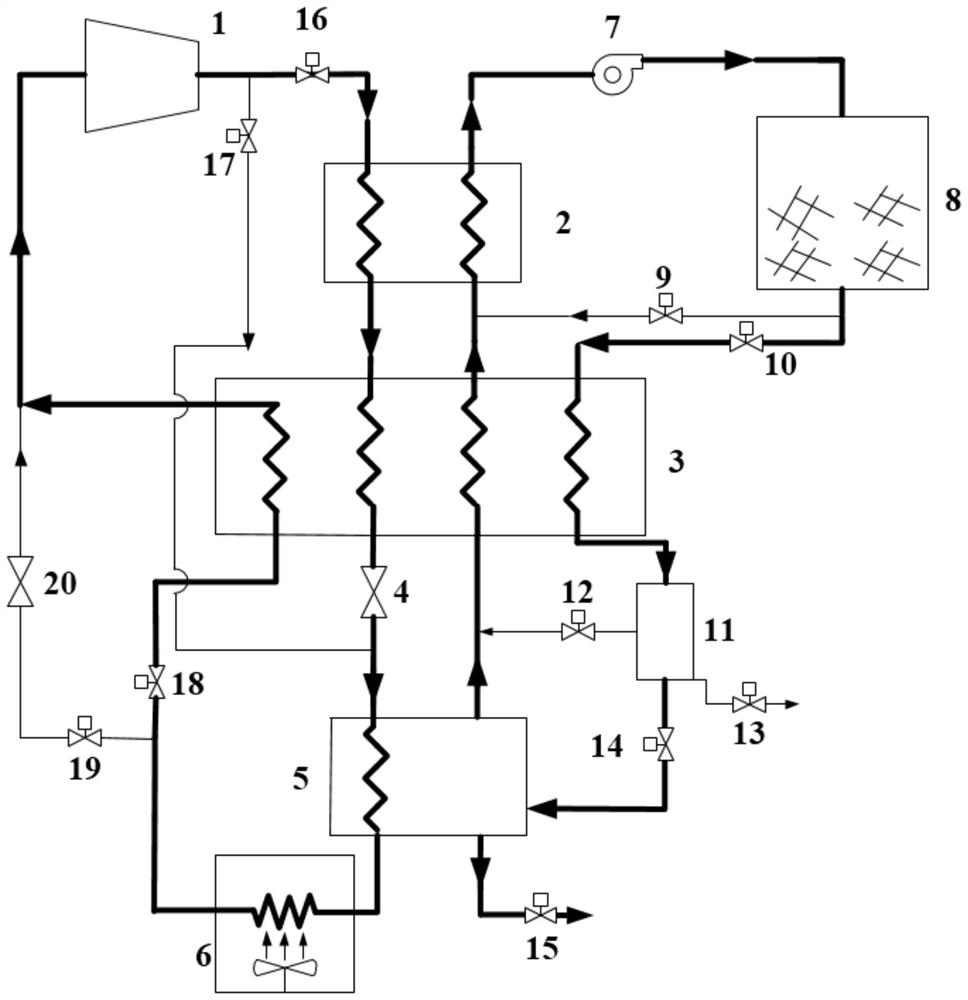

[0063] see image 3 , is a schematic diagram of the non-winter operation mode of the air source large temperature span high temperature heat pump system provided by an embodiment.

[0064] The air source large temperature span high temperature heat pump drying system includes a non-winter drying operation mode, and the non-winter drying operation mode works as follows:

[0065]The first shut-off valve 9 is closed, the third shut-off valve 12 is closed, the sixth shut-off valve 17 is closed, the eighth shut-off valve 19 is closed, the first liquid discharge valve 13 is closed, and the second shut-off valve is closed. The liquid discharge valve 15 is closed, the second shut-off valve 15 is opened, the fourth shut-off valve 14 is opened, the fifth shut-off valve 16 is opened, the seventh shut-off valve 18 is opened, and the high-pressure outlet of the compressor 1 The discharged high-temperature working fluid enters the condenser 2 to heat the air through the fifth cut-off valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com