A preparation method of blank solution in polytetrahydrofuran base value determination method

A technology of polytetrahydrofuran base number and blank solution, which is applied in the direction of chemical analysis by titration method, can solve the problems of titration liquid concentration change, unstable base number measurement, large error in the base number measurement result, etc. Number of times, reliable technical support, and the effect of mentioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

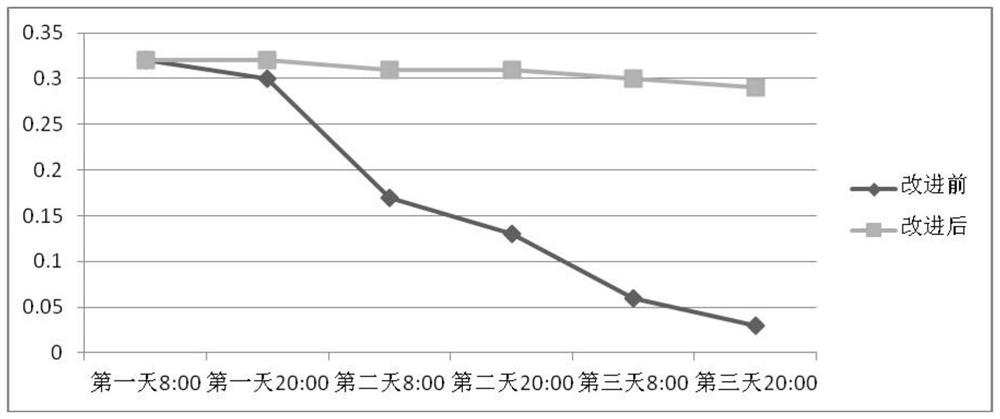

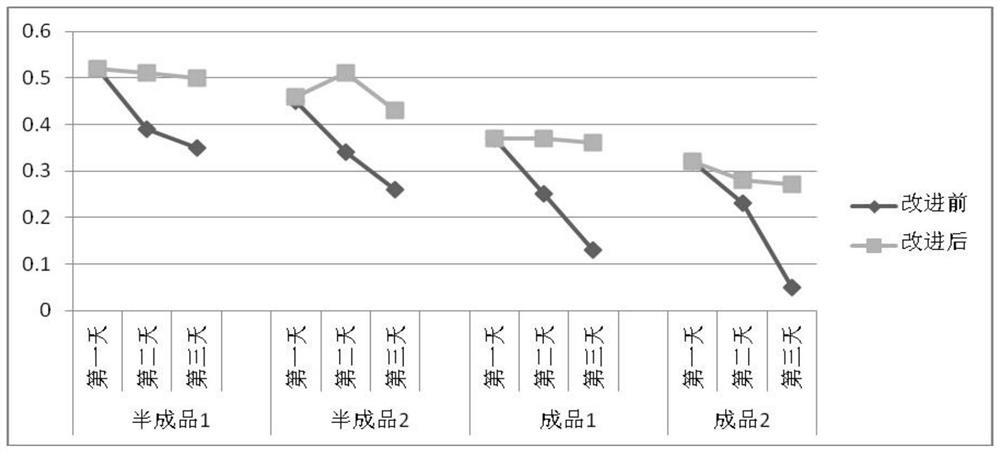

Examples

Embodiment 1

[0029] This embodiment provides a method for preparing a blank solution in a polytetrahydrofuran base value determination method, comprising the following steps:

[0030] Prepare the solution before preparing the solution. Wash the glass bottle, the magnet of the stirring device, the measuring cylinder, the beaker, the alkaline burette, the glass bottle stopper, etc. repeatedly with distilled water for 3 to 5 times, and dry them for later use.

[0031] Step 1: Add 9500ml methanol solution with a content of 99.9% to the glass bottle, then add 400ml high-purity water and 0.8ml, 0.5mol / L sodium hydroxide solution to the methanol solution, use 2 to 3 magnets to put Stir in a glass bottle with a magnetic stirring device, and stir for the first time for 8 hours to make a methanol solution of sodium hydroxide;

[0032] Step 2: leave the methanol solution of sodium hydroxide in step 1 open for 12 hours at room temperature;

[0033] Step 3: Stir the methanol solution of sodium hydroxi...

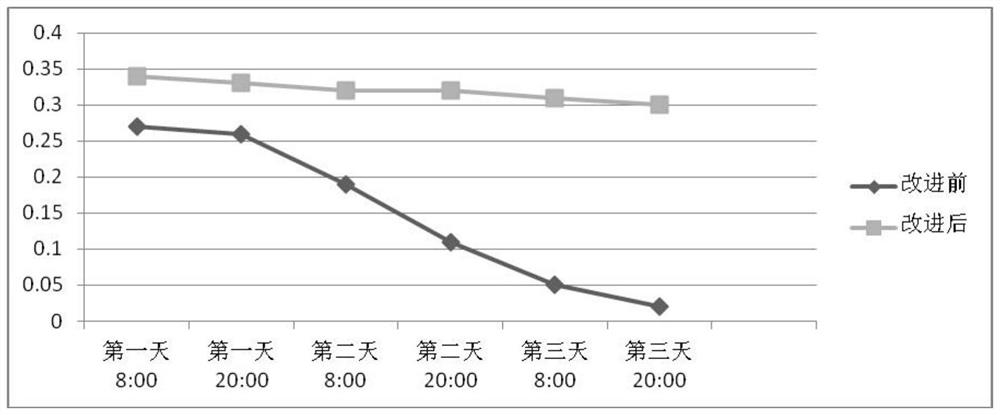

Embodiment 2

[0036] This embodiment provides another method for preparing a blank solution in the polytetrahydrofuran base value determination method, which includes the following steps:

[0037] Prepare the solution before preparing the solution. Wash the glass bottle, the stirring rod of the stirring device, the measuring cylinder, the beaker, the alkaline burette, the glass bottle stopper, etc. repeatedly with distilled water for 3 to 5 times, and dry them for later use.

[0038] Step 1: Add 9500ml of methanol solution with a content of 99.9% to the glass bottle, then add 400ml of high-purity water and 0.8ml, 0.5mol / L sodium hydroxide solution to the methanol solution, put the stirring rod into the glass bottle and use the stirring device Stir, make the methanol solution of sodium hydroxide through first stirring 8h;

[0039] Step 2: leave the methanol solution of sodium hydroxide in step 1 open for 12 hours at room temperature;

[0040] Step 3: Stir the methanol solution of sodium hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com