An extremely low reverse recovery charge superjunction power vdmos

A technology of reverse recovery charge and power, applied in circuits, electrical components, electric solid-state devices, etc., can solve problems such as improving the reverse recovery characteristics of SJ-VDMOS body diodes, the level of limited freewheeling current, and the increase of leakage current , to achieve excellent reverse recovery characteristics, improve reverse recovery characteristics, and reduce the effect of Qrr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

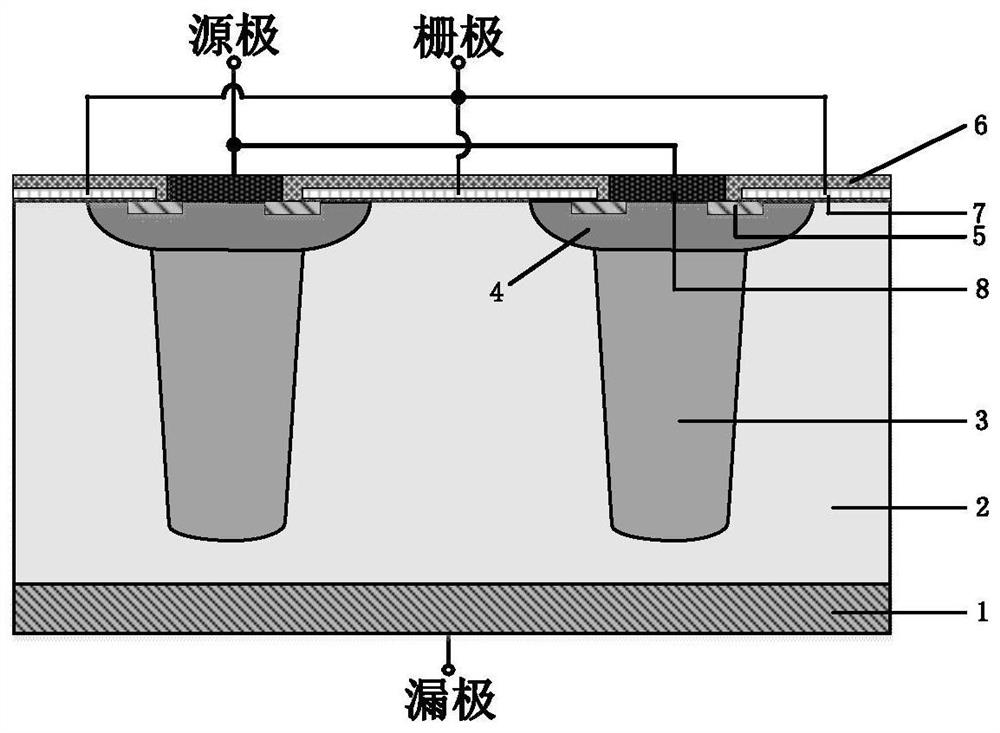

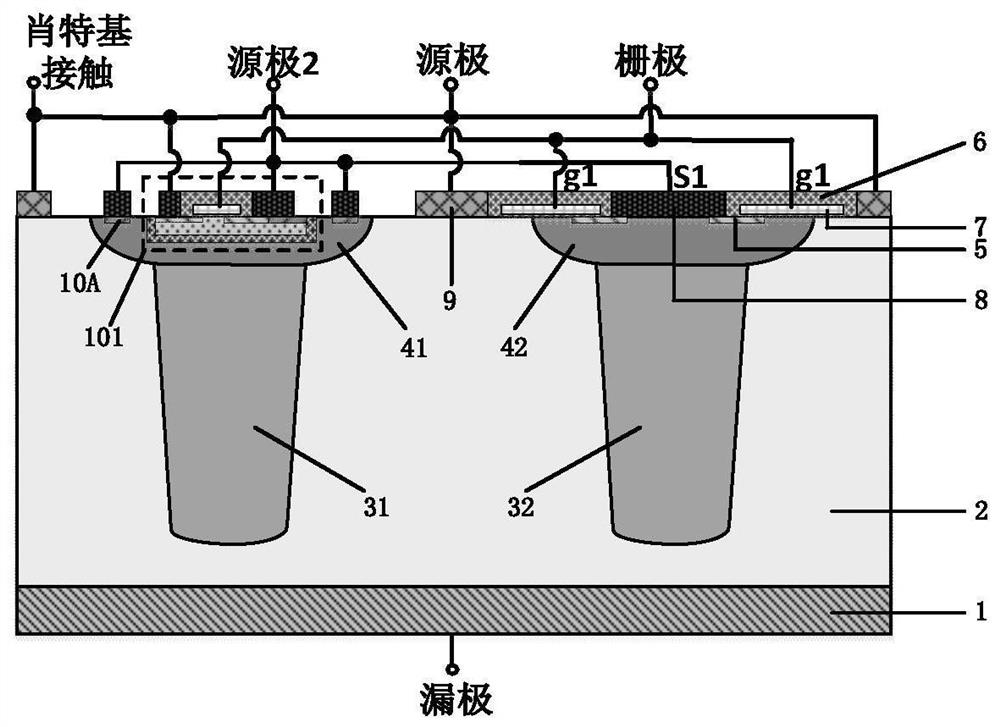

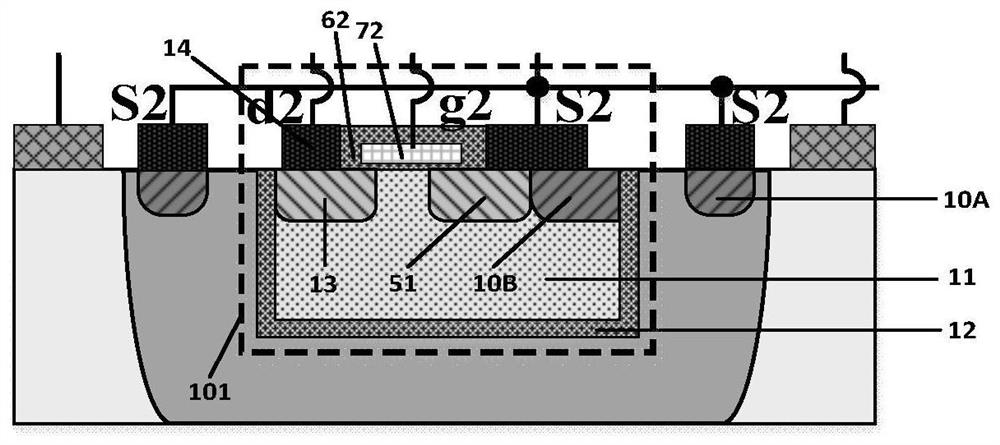

[0022] An extremely low reverse recovery charge superjunction power VDMOS, including a superjunction VDMOS, the superjunction VDMOS includes an N-type substrate 1 that doubles as a drain and an N-type drift region 2 disposed on the N-type substrate 1 , which is characterized in that a first P column 31 is provided in the N-type drift region 2 of the super junction VDMOS, and a first P-type body region 41 is provided on the top of the first P column 31, and the first P-type body region 41 The top surface is flush with the top surface of the N-type drift region 2, an N MOS transistor 101 is arranged on the first P-type body region 41, and an NMOS transistor 101 is arranged between the N MOS transistor 101 and the first P-type body region 41. With SiO 2 The isolation layer 12 is further provided with a first P-type heavily doped region 10A on the first P-type body region 41, the source metal of the super junction VDMOS, the source metal of the N MOS transistor 101 and the first P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com